Materail: Rock gold

Input size: >210mm

Process: Feeding> Crushing> Grinding> Leaching and Activated Carbon Adsorption processing> Gold-loaded carbon desorption and electrolytic Stage> Tailing Water recycle

Process Description

The carbon slurry gold extraction process (CIP method) is one of the methods of cyanide gold extraction.

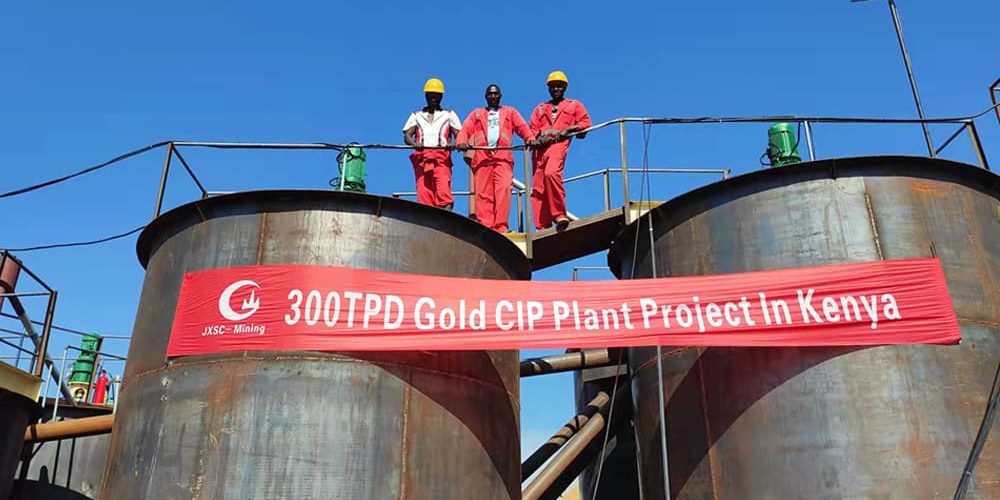

JXSC designed the flow chart of the processing line and provided the customer with a complete set of equipment. JXSC’s professional engineers go to the mining site to help customers install and use equipment.

1. Feeding + Crushing

The raw ore is larger than 210mm, and the material needs to be processed to a suitable size before beneficiation. The Chute Feeder sends materials to the crushing system. Rough Jaw crusher, Fine jaw crusher, and Roller Crusher work together to crush 210mm ore to less than 5mm.

Equipment: Feeding Hopper+Chute Feeder+ Rough Jaw crusher+belt conveyor+Fine jaw crusher+vibration

2. Grinding

The crushed materials enter the ball mill and are ground to 200 mesh. The grinding process is fed by an Electromagnetic vibration feeder and hydroCyclone classifies the slurry.

Equipment: Storage Bin+ Electromagnetic vibration feeder+ belt conveyor+Ball mill+HydroCyclone

3. Leaching Pretreatment

The material is concentrated and dehydrated through Thickener, and impurities such as sawdust are removed, and the slurry concentration is adjusted to a suitable concentration.

Equipment: Thickener + Agitation tank (for adjusting the density of slurry after thickener) +Liner vibrating

4. Leaching and Activated Carbon Adsorption processing

Materials are stirred and leached. The cyanide slurry enters the stirring adsorption tank, and activated carbon flows in the reverse direction to adsorb the dissolved gold in the slurry.

Equipment: tanks+ Roots blower (work for adsorption agitation tank)+ Liner vibrating screen for tailing

dewatering+ Liner vibrating screen for screening carbon+ Cabon extractor +Cabon screen

5. Gold-loaded carbon desorption and electrolytic Stage

The gold-loaded carbon is separated from the slurry with the help of a carbon extraction screen, and the gold complex is replaced in the desorption system. The sorted ore is dried and smelted into blocks using a Gold smelting furnace.

Equipment: normal temperature& normal pressure Elution & Electrolysis system+Drying Oven for gold

mud+ Gold smelting furnace

6. Carbon kiln for carbon regeneration

The desorbed activated carbon is first pickled with dilute sulfuric acid (nitric acid) to remove carbonate and other accumulations. After being returned to use several times, it needs to be thermally activated to restore the adsorption activity of the carbon.

7. Tailing Water recycling system

Cyanide-containing leached slurry cannot be discharged directly and must be processed by the tailings water recovery system.

High-pressure slurry pump+plate filter press+cone slurry tank for making the suitable density of the slurry before sending it to filter

8. FIVE Reagent adding devices system

Equipment: each system includes a reagent agitation tank+reagent slurry pump+ reagent tank.

(1) Flocculant make-up system for thickener

(2) sodium cyanide reagent make-up system for 2pcs leaching agitation tank

(3) Lime make-up system for 2pcs leaching agitation tank (for PH control)

(4) sodium hydroxide&hydrochloric acid reagent make-up system for cone agitation tank

(5) sodium hydroxide&&clean water&sodium cyanide reagent make-up system for Elution &

Electrolysis system

Other equipment:

(1) Water pumps for water supply to complete plant

(2) Slurry Pumps for plant

(3)Complete set of electric control panels

(4) Complete set Cables&wires

(5) Diesel Generator for plant machines power

(6) Complete set of Water pipes &slurry pipes