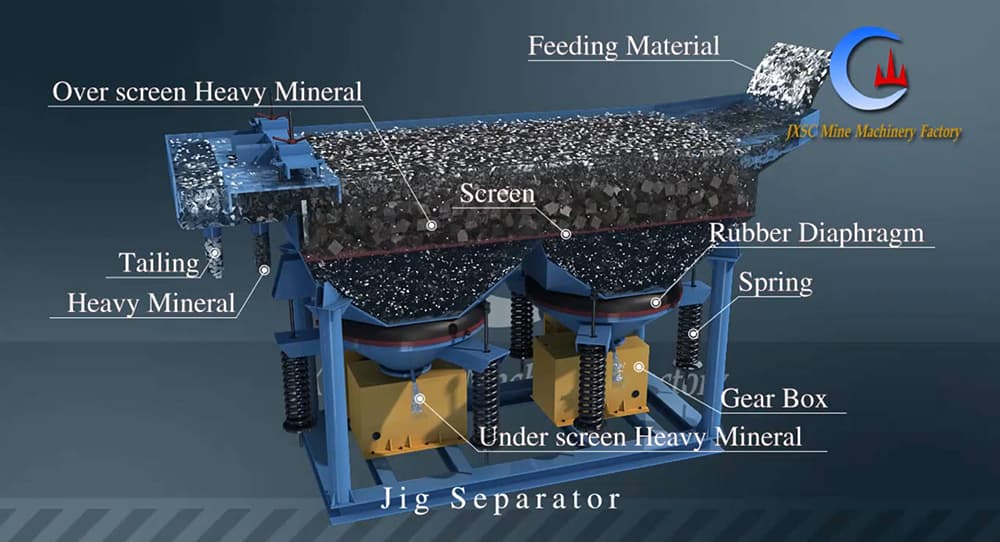

Jig Separator

Capacity:1-25 t/h

Applicable materials: diamond, placer gold, alluvial gold, tantalum niobium, titanium, tungsten, iron, tin, hematite, dolomite, manganese, barite, etc.

Description

Jig separator belongs to the coarse separation equipment. The greater the difference in specific gravity and density in the raw ore, the better the sorting effect will be. The number of wave boxes of the Jig separator can be customized. One wave box is commonly used for fine-grained minerals, and two wave boxes are commonly used for large-grained materials. According to different equipment structures and water flow movement methods, jigs can be divided into the following types: piston Jig separator, diaphragm Jig separator, air pulsation Jig separator, and moving screen Jig separator.

We have customized Jig separator for customers, which is suitable for sorting gold ore, diamonds, tantalum-niobium ore and other minerals. We have rich production experience. Welcome to consult!

Advantages

- The processing particle size range is wide, and both fine-grained materials and coarse-grained materials can be sorted.

- The machine occupies a small area and has a large processing capacity.

- Can use recycled water, energy saving and environmental protection.

- The sorting efficiency is high and the concentrate recovery effect is good.

- The pulsation speed easy to adjust.

Principle

The jig separator uses the different settling speeds of minerals with different specific gravity in the water flow to perform sorting work. The jig chamber agitate water flow, and the water flows through the screen of the jig chamber, pushing up the mineral deposits and making them in a loose state. Minerals with high density settle quickly in the water and fall to the bottom layer; minerals with low density settle slowly in the water and are transferred to the upper layer. . When the water flow drops, the fine particles with high density can enter the lower layer through the increasingly tight gaps in the mineral deposit, thereby achieving stratification of light and heavy minerals.

Specification

| Model | jigging chamber | diaphragm | Feeding size(MM) | Back Wash Water (M3/H) | Back Wash Water Pressure(Mpa) | Process Capacity (T/H) | Motor power (KW) | Dimension (MM) | Weight (Ton) | ||

| Shape | Area | Stroke | Jig frequency | ||||||||

| JT0.57-1 | Trapezoid | 0.57 | 10-17 | 80-120 | <10 | 18-20 | ≥0.1 | 1-3 | 1.5 | 1550x780x1530 | 0.6 |

| JT1-1 | Trapezoid | 1.1 | 10-17 | <10 | 20-30 | 2-4 | 2.2 | 2270x1110x1890 | 0.9 | ||

| JT2-2 | Trapezoid | 2.3 | 10-17 | 60-100 | <25 | 40-50 | 4-8 | 3 | 2900x1550x2000 | 1.4 | |

| JT4-2 | Trapezoid | 4.5 | 20-30 | <25 | 80-100 | 10-15 | 7.5 | 3900x2000x2460 | 3.2 | ||

| JT4-2A | Trapezoid | 4.5 | 20-30 | <25 | 80-100 | 10-15 | 4*2pc | 3900x2000x2460 | 4 | ||

| JT5-2 | Trapezoid | 5 | 20-30 | <25 | 80-100 | 10-20 | 7.5 | 4000x2050x2660 | 3.2 | ||

| JT6-3 | Trapezoid | 6.8 | 20-30 | <25 | 120-150 | 20-25 | 7.5+4 | 5400x2000x2460 | 5 | ||