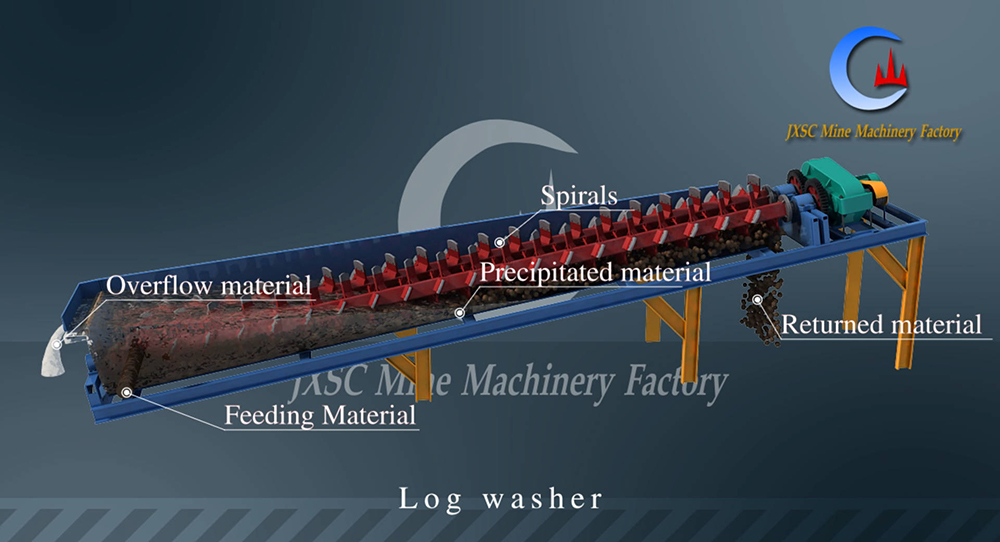

Log Washer

In the mining sector, high-efficiency cleaning equipment is critical for upgrading raw material quality. The log washer, with its unique spiral design, stands out as an essential solution for effectively processing argillaceous minerals.

Capacity:

10-100 t/h

Applicable materials:

Commonly used for washing and separating sludge and stains from primary minerals such as manganese ore, iron ore, fluorite ore, gold ore, hard kaolin, iron ore, ilmenite, phosphate ore, tungsten ore, tin ore, limestone, etc.

What is Log washer

Log washers, also called spiral washing machines, specialize in scrubbing challenging mining materials with heavy clay content, stubborn viscosity, and mudball clusters. These robust machines deliver three-in-one processing – combining intense mixing, thorough washing, and effective desliming – making them ideal for iron ore beneficiation and aggregate purification.

JXSC’s customizable single/double spiral log washers feature enhanced abrasion plates and optimized spiral rotation speeds. Their counter-rotating mechanisms achieve 30% higher scrubbing efficiency than conventional models, particularly effective in processing alluvial deposits and weathered ores common in mining operations.

Advantages

- The spiral body is long, the mud removal effect is remarkable, and the sealing system is good;

- The log washer is often used to clean ores with large amounts of mud and has a strong scrubbing effect;

- The spiral blades are wear-resistant, adaptable to various materials and can be replaced;

- It has large processing capacity, low energy consumption and easy maintenance.

Principle

The motor of the log washer drives the two spiral impellers to rotate in different directions through the reducer. The blades vigorously stir the materials entering the tank. Materials of various phases and fine sizes tumble, rub and collide. Mud clumps and stickiness are fully decomposed, and impurities covering the mineral surface are eluted. Due to the buoyancy of the water, the water flow in the washing tank takes away impurities and fine particles in time and discharges them from the bottom outlet. The cleaned minerals are scraped by the blades and removed from the sand return port at the top, thereby realizing the materials’ washing, classification and desliming.

Specification

| Model | Spiral Dia.(mm) | Rotating Speed(r/min) | Feeding Size(mm) | Tank Slope(o) | Process Capacity(t/h) | Motor Power(kw) | Weight(T) |

| 2RXL320 | 750 | 28 | ≤30 | ≤12 | 10 | 4 | 0.9 |

| 2RXL400 | 750 | 23 | ≤30 | ≤12 | 20 | 5.5 | 1.9 |

| 2RXL540 | 1000 | 23 | ≤30 | ≤12 | 25 | 7.5 | 3.9 |

| 2RXL750 | 1000 | 22.7 | ≤70 | ≤12 | 50 | 40 | 17.2 |

| 2RXL800 | 1200 | 22 | ≤70 | ≤12 | 70 | 45 | 18.9 |

| 2RXL914 | 1200 | 21 | ≤70 | ≤12 | 100 | 55 | 23 |