Turnkey Solutions

Copper Processing Plant

In a copper processing plant, ore containing sulfide and oxide copper undergoes specialized beneficiation. Copper flotation plants focus on sulfide recovery via froth separation, while gravity methods concentrate oxidized copper. For mixed ores, concentrator workflows combine both: gravity separation extracts oxide copper first, followed by flotation for sulfide enrichment. Modern copper processing plants employ integrated beneficiation systems to maximize recovery from complex ores.

Copper Process

Oxidized copper processing plant

1. Crushing and grinding

The oxidized copper ore enters the jaw crusher for crushing. The crushed material enters the second jaw crusher to get fine copper ore. After the crushing process, the copper ore is transported to the vibrating screen for screening, and the materials that meet the requirements are screened out and transported by the conveyor to the material bin for the next step of the process. After crushing and screening, the material enters the ball mill for wet grinding, and the slurry from the ball mill enters the spiral classifier for classification. The spiral classifier sends the unqualified material to the ball mill for further grinding.

2.Gravity and Magnetic Separation

After crushing and grinding is the separation process. It usually uses gravity separation equipment like the shaking table. If the processing plant capacity is large, use the spiral chute and the shaking table for gravity separation. If there are magnetic metals that need to be recycled, add a magnetic separator in the processing plant to remove iron before gravity separation (if the processing capacity is large, use spiral chutes first and then use magnetic separators to remove iron).

Sulfide oxide mixed copper ore beneficiation plant

1. After crushing and grinding, the oxidized ore is treated with gravity separation equipment (for larger capacities, the copper ore goes to a spiral chute for separation, and then to the shaking table for concentration. For smaller capacities, use the shaking tables). The tailings of the shaking table enter the flotation equipment for processing.

2. The qualified pulp materials enter the mixing tank, where the materials are fully mixed. The mixed materials enter the flotation machine for flotation. After the pulp and reagents fully react in the flotation machine, the foam is generated on the machine. The foam containing minerals is sent to the foam tank by the rotating scraper to enter the following process. The tailings are transported to other places for treatment, while the concentrate will go to a concentration tank for concentration and sedimentation. After concentration and sedimentation, the copper concentrate will be dried to obtain finished copper powder.

3.If it needs to recycle the iron, add a magnetic separator to remove iron before gravity separation (if the processing capacity is large, use a spiral chute first and then use a magnetic separator to remove iron)

Related Case

Ore Type: Oxide copper ore

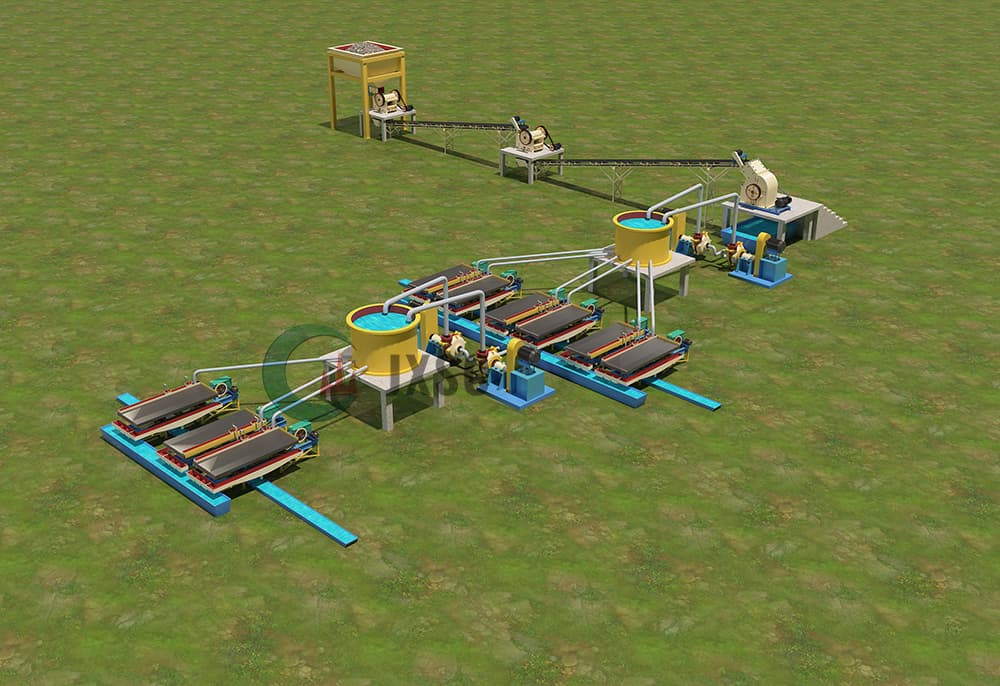

Hopper->Vibrating Feeder->Trommel Scrubber->Vibration Screen ->ball mill ->Slurry Pump->Shaking Table

- The truck unloads the copper ore to the hopper, and the vibrating feeder under the hopper transports the copper ore evenly to the trommel scrubber by belt conveyor for washing clay and screening big copper stones. The big copper stones fall to the jaw crusher for crushing, then the materials enter the vibrating screen for separation. After the screening, the material that meets the requirements will go to the ball mill.

- After grinding, the slurry from the ball mill will flow to the slurry tank. Use the slurry pump to pump the slurry to the distribution tank. The slurry in the distribution tank will flow to the shaking table for separation.

We supplied the complete plant for this copper project.

- Customer provides the hopper.

- Vibration Feeder, Capacity 10tph.

- Trommel Scrubber Washing Machine, Capacity 10tph.

- Vibration Screen Machine, Capacity 10TPH.

- Ball Mill Machine, Capacity 10TPH.

- Shaking table, 10 sets.