In nature, chromium often forms chromite with iron, and its main components are iron, magnesium, and chromium oxides. Chromium-magnesia spinel or chromium-iron spinel minerals are common forms. In the mineral processing process, different mineral beneficiation processes can be used for different types of chrome ores.

1. Separation of chrome ore with different chromium oxide content.

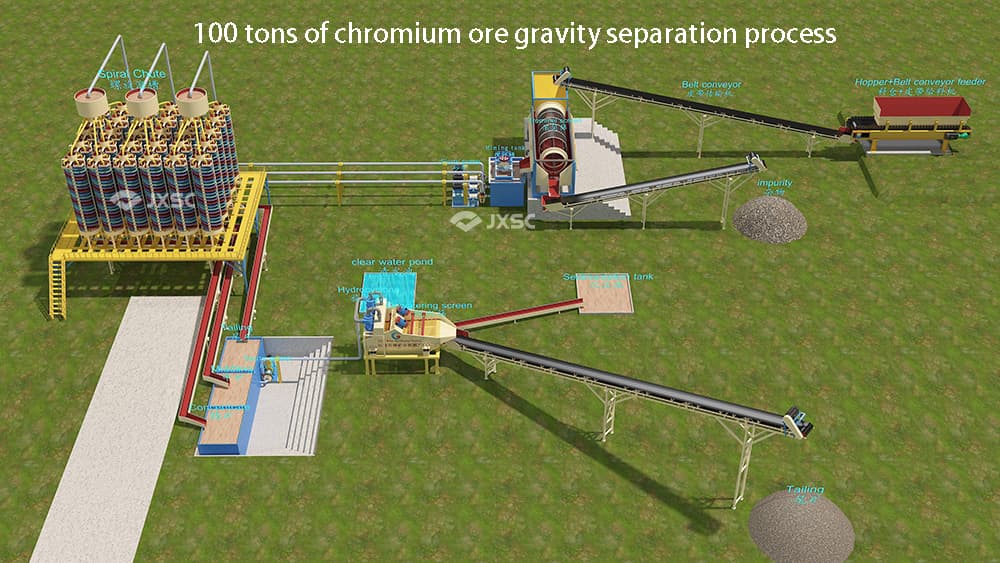

For rich ores with high chromium oxide content, a single gravity separation or magnetic separation process can be adopted. For chromium ores with lower chromium oxide content, it is necessary to consider using a combined magnetic-gravimetric process to obtain better indicators. The specific process flow needs to be determined according to the properties of the ore.

2. Chromite rock ore and placer beneficiation.

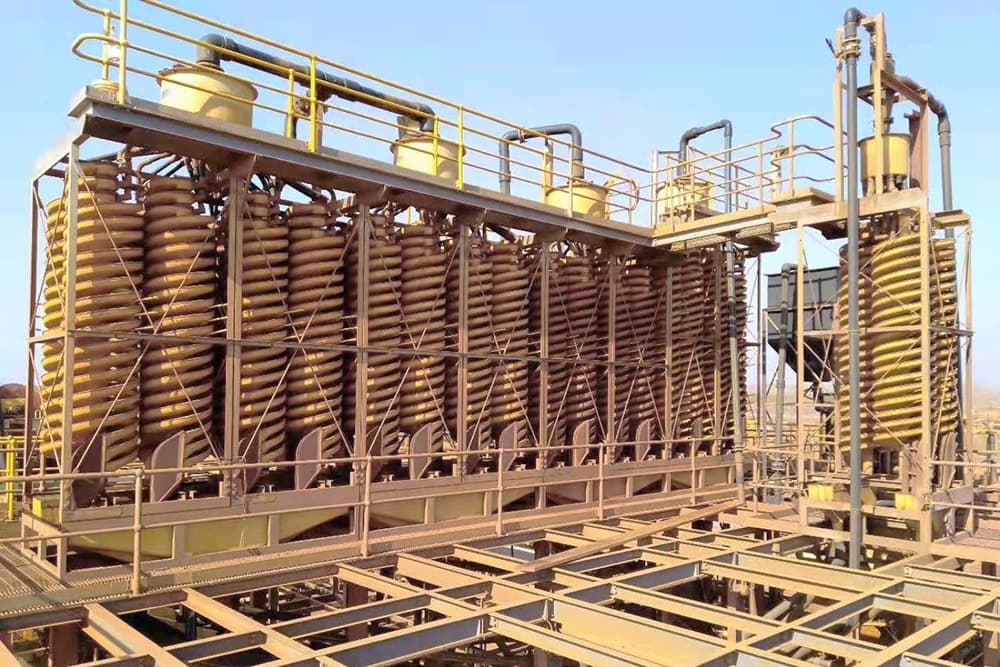

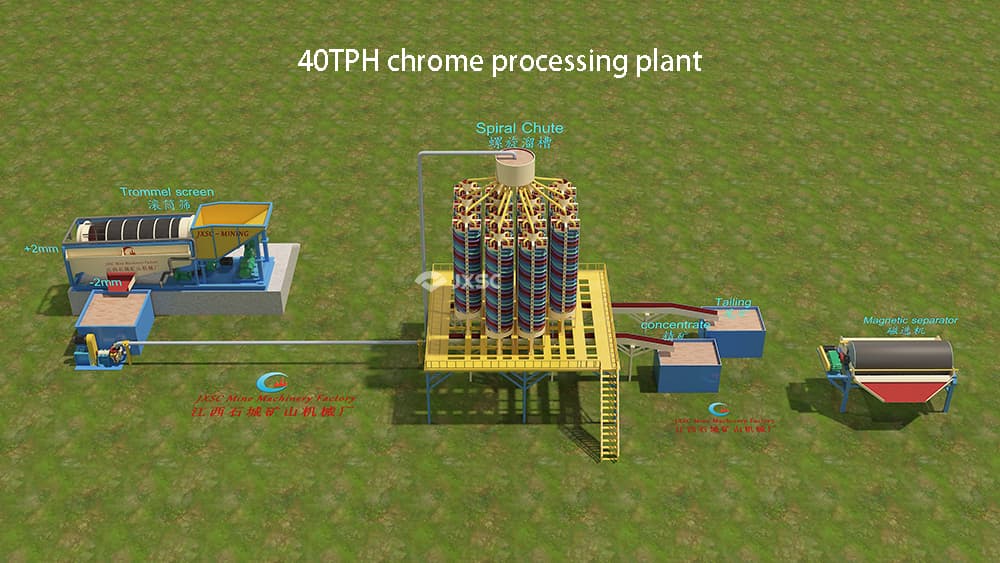

Chromite ore beneficiation and chromite placer beneficiation are two common types of chromium ore. Chromite ore beneficiation usually requires the use of crushers, rod mills, jig separator, and other equipment, while chromite sand ore beneficiation usually only requires the use of washers, jigs, spiral chutes, and other equipment. Although the shaking table is also a commonly used gravity separation equipment, it is usually used for the repurification of chromite concentrate or tailings sweeping to improve the recovery rate.

3. Selection of magnetic separator

In the process of beneficiation, weak magnetic beneficiation, and strong magnetic beneficiation are commonly used methods. The weak magnetic separator can remove magnetite, improve the chromium-iron ratio of the concentrate, and further enrich qualified chromite concentrate products. The strong magnetic separator can recover chromite and separate gangue minerals. It is especially suitable for situations where fine-grained minerals are not suitable for gravity separation.

4. Chrome ore flotation processing.

In addition, flotation mineral processing is also a method of processing fine-grained chromite ore, which requires the use of a flotation machine and flotation reagents. Although the flotation process is complex and the power consumption and chemical costs are high, it can be considered when gravity separation and strong magnetic separation are not effective.

In summary, the selection of chromium ore beneficiation technology should be determined based on the properties of the ore and the content of various components to achieve the best beneficiation effect.