Gold processing plant

JXSC Gold Solutions Since 1985

• Custom-built gold processing plant designs

• Advanced beneficiation process for 98%+ recovery rates

• Premium gold mining equipment for sale (ISO-certified)

• Specialization: alluvial, rock & sulfide gold ores

• On-site engineering support & lifetime maintenance

Why Choose Us?

Integrated solutions from ore analysis to final recovery, using wear-resistant equipment that reduces operational costs by 30-45%.

Gold Ore Processing

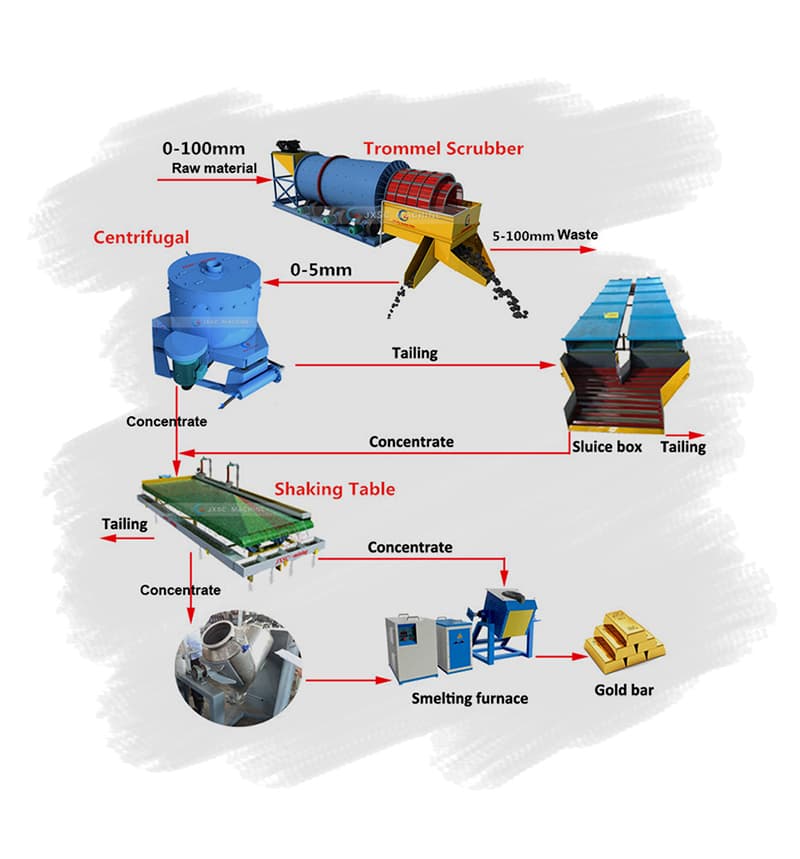

A modern gold processing plant typically combines multiple stages to maximize recovery efficiency:

1. Crushing Process

Essential for liberating gold from host rock, the crushing stage controls ore particle size and enhances mineralization for optimized downstream processing.

2. Washing System

Gold trommel scrubbers in processing plants remove clay contaminants and improve extraction rates through vigorous material scrubbing.

3. Gravity Separation

Utilizing density differences, this cost-effective method achieves 60-85% gold recovery through equipment like centrifugal concentrators, ideal for both hard rock and alluvial deposits.

4. Flotation

Critical for sulfide gold processing, this method separates gold-bearing minerals via air bubbles, achieving 85-93% recovery rates in complex ore treatment.

5. CIP Method

The carbon-in-pulp (CIP) process uses activated carbon to directly recover gold from cyanide solutions, maintaining 90-96% recovery rates across various ore grades.

6. CIL Enhancement

The carbon-in-leach (CIL) method enhances CIP efficiency by combining leaching and adsorption processes in gold processing plant operations, reducing processing time by 15-20%.

Gold Beneficiation Plant

For different types of gold ores including alluvial gold, rock gold, and sulfide gold, JXSC tailors the gold beneficiation process for you to optimize efficiency.

Mobile, Portable and Small Scale Gold Washing Equipment for Sale

Customize your ideal mobile gold wash plant with a range of washing and sorting equipment options. Popular choices ready for selection!

JXSC has designed efficient gold ore processing plant for many customers around the world. Please send us your mineral mining information. A technician will contact you immediately.

Free design of gold ore beneficiation process. Provide ore sample testing services. Turnkey solution.

Products are produced in strict accordance with international standards. One year warranty, accessories provided.

Engineers provide on-site guidance on installation and commissioning of equipment.