In the modern metallurgical industry, the iron ore beneficiation process plays a decisive role in the final concentrate quality. Different types of iron ore have different physical and chemical properties and require corresponding beneficiation technologies.

1. Ore beneficiation technology of strong magnetic magnetite

Magnetite is the leader of the iron ore family and is rich in iron content, often exceeding 80%. The most notable feature of this ore is its strong magnetism, which provides natural advantages for its mineral processing process.

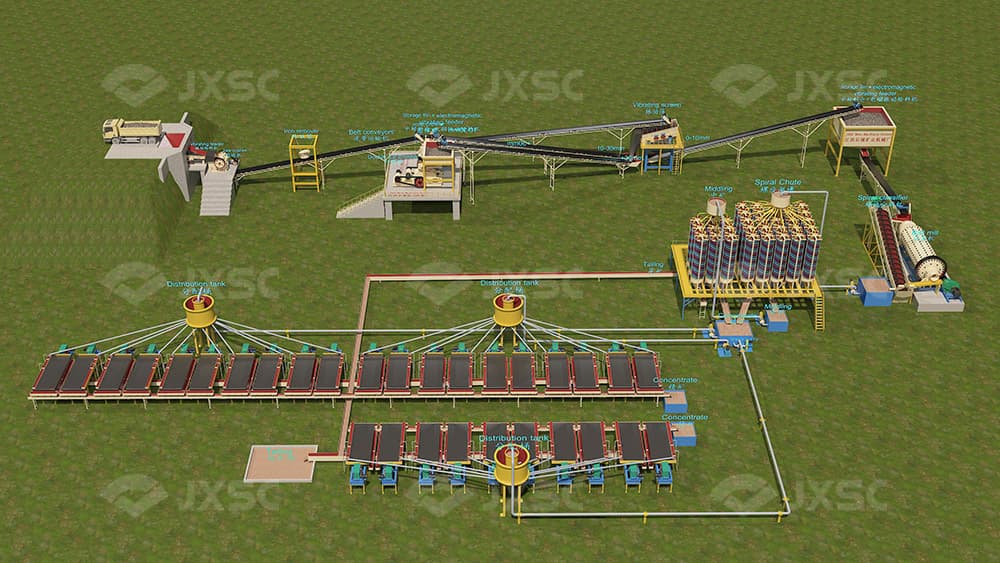

Industrial practice shows that magnetite has the most ideal mineral processing effect. By adopting the process route of “coarse crushing–magnetic separation and pre-finishing-stage grinding-grading”, we can not only significantly reduce production costs, but also obtain high-quality concentrate products. Actual production data shows that using this process, ore with a raw ore grade of 23.44% can be upgraded to a concentrate grade of 64.18%, while maintaining a high iron recovery rate of 73.74%.

2. Quality improvement and efficiency improvement of weakly magnetic hematite

Although hematite has a moderate iron content (about 50%), due to its weak magnetic characteristics, the beneficiation process design is relatively complex. This type of ore mainly exists in the form of iron oxide and includes multiple subtypes, such as titanium hematite, aluminum hematite, etc.

In view of the characteristics of hematite, the innovative “continuous grinding-multi-stage magnetic separation-reverse flotation” combined process is adopted in industrial production. The unique features of this process are:

First of all, continuous grinding is used to replace traditional stage grinding, which effectively prevents losses caused by excessive grinding. Secondly, through the combined application of weak magnetic separation and strong magnetic separation, primary and secondary sludge were successfully separated, creating favorable conditions for the subsequent reverse flotation process. Finally, anion reverse flotation technology was used to further improve the quality of the concentrate.

3. Treatment plan for special limonite

The beneficiation of limonite is relatively difficult, mainly because its iron content is relatively low (35-40%) and its crystal water content is high, making it prone to sludge during grinding. These characteristics bring challenges to traditional mineral processing methods, and it is often difficult to achieve the concentrate grade requirement of more than 60%.

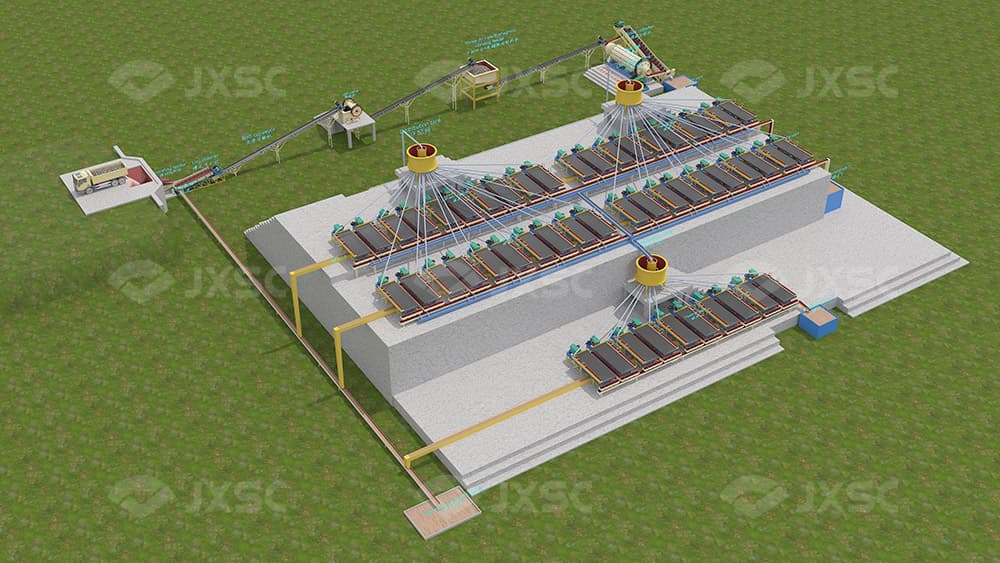

In response to these characteristics of limonite, various treatment options have been developed in industrial practice:

A single beneficiation process can be used, such as gravity separation or flotation

A combined process of magnetic separation and flotation can also be used

In some cases, a combination of reduction roasting, magnetic separation and leaching is also a viable option.

In actual production, the beneficiation processes of different iron ores need to be optimized and adjusted according to specific conditions. In addition to the above three main ores, for other types of iron ores such as siderite and ilmenite, detailed ore property analysis is also required to formulate reasonable process plans.

The final process selection should be considered comprehensively. Such as the physical and chemical properties of the ore itself, environmental protection requirements, equipment investment costs and other factors.

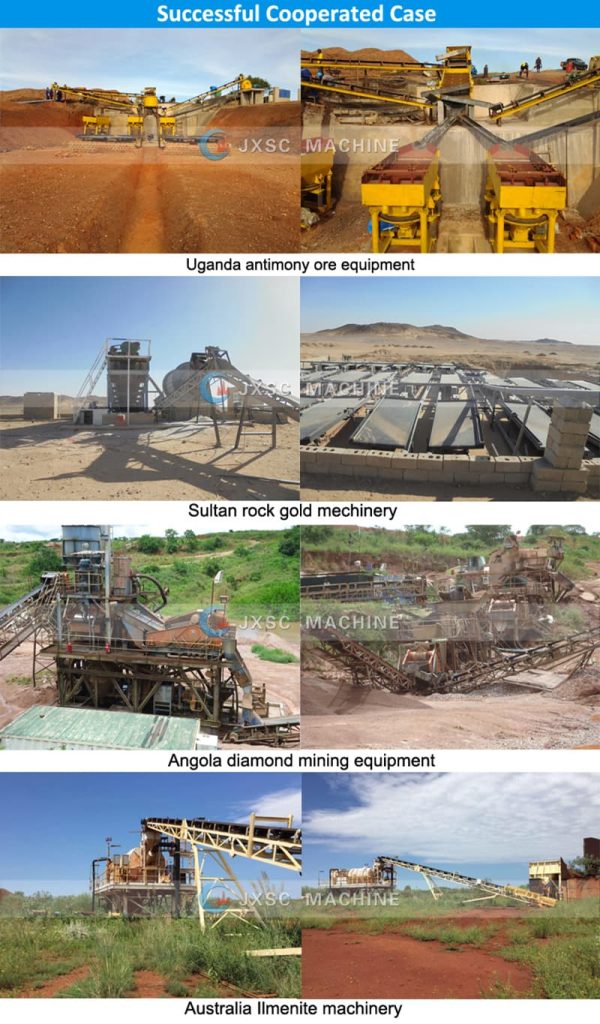

JXSC has 38 years of experience in the mining industry, and many experienced engineers provide professional technical support to customers. We focus on providing turnkey solutions and full equipment sales services for mining. Over the years, we have served hundreds of customers at home and abroad. Please send us your mining information. JXSC can provide more accurate suggestions based on your specific situation.