Copper ore beneficiation is the process of separating copper minerals in ores from other gangues, mainly using technologies such as flotation, leaching-extraction-electrolysis, and priority flotation. Different types of copper ores are suitable for different beneficiation methods. The following is a detailed introduction to these methods and common copper ore types.

Main beneficiation methods for copper ore

1. Flotation process

Scope of application: sulfide copper ore (such as chalcopyrite and azurite)

Main steps: crushing, grinding, flotation (roughing – concentrating – scavenging)

Principle: This method uses the difference in surface properties between copper minerals and gangue minerals. By adding collectors and frothers, copper minerals are selectively attached to bubbles, thereby separating them from gangue. Flotation has a high recovery rate and is the most commonly used method in copper ore dressing.

2. Leaching-extraction-electrolysis process

Scope of application: oxidized copper ore (such as cuprite and ferrocopper ore)

Process flow: acid leaching → solvent extraction → electrolysis

Features: This method can directly obtain electrolytic copper products. Although the cost is high, the product purity is relatively high. Through acid leaching, the oxidized copper ore is converted into soluble copper salts, and then copper is obtained through extraction and electrolysis.

3. Preferential flotation process

Scope of application: mixed copper ore

Process flow: first float sulfide ore, then treat oxidized ore

Features: This method can handle complex mixed ores, first separate sulfide ore, and then treat oxidized ore, which improves the overall recovery rate.

Common types of copper ores and their beneficiation methods

1. Sulfide copper ore

Mainly includes chalcopyrite and azurite, usually in the form of sulfide. The beneficiation method includes grinding, flotation and leaching. After the ore is crushed and ground, high-purity copper concentrate is separated by flotation.

2. Oxidized copper ore

The main components are oxides or hydroxides, such as cuprite and black copper ore. Flotation is usually not required in the beneficiation process. Leaching, heap leaching and extraction are mainly used, which can convert oxidized copper ore into soluble copper salts for further processing.

3. Placer copper ore

This ore is a mixture of copper ore and muddy or fine-grained rock. The beneficiation method includes crushing, grinding and re-selection to increase the copper content in the ore.

In addition to the above types, there are other special types of copper ore, such as copper-containing coarse sand and copper-molybdenum ore. For different types of copper ore, detailed ore characteristic analysis and beneficiation experiments are required to determine the appropriate beneficiation method.

The choice of copper ore beneficiation method depends on the type and characteristics of the ore. Flotation, leaching-extraction-electrolysis and preferential flotation are the most commonly used technologies, each of which has its scope of application and advantages and disadvantages. In actual operation, it is crucial to choose a suitable beneficiation method by comprehensively considering the ore characteristics and economic benefits.

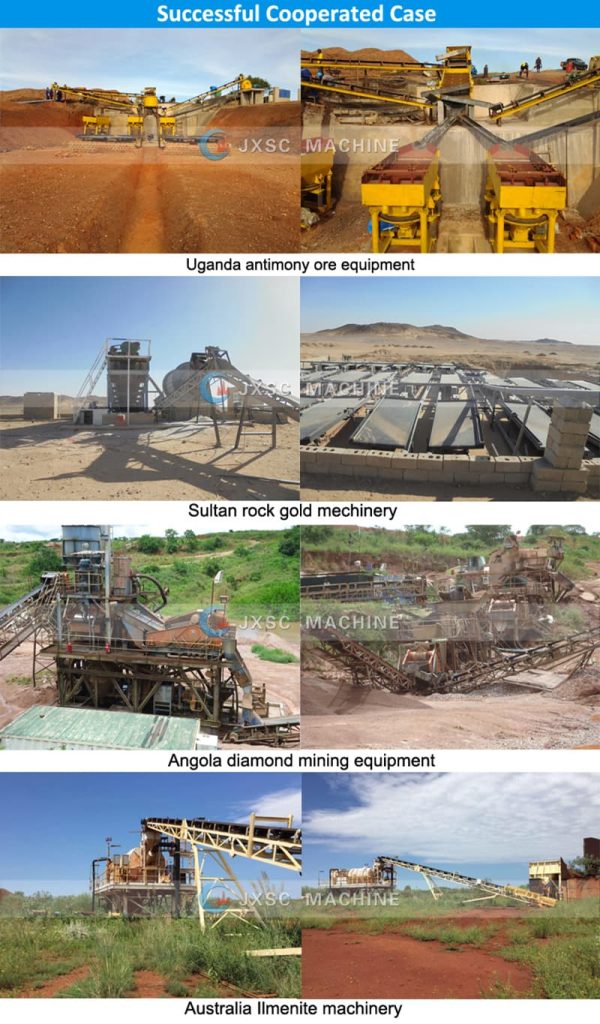

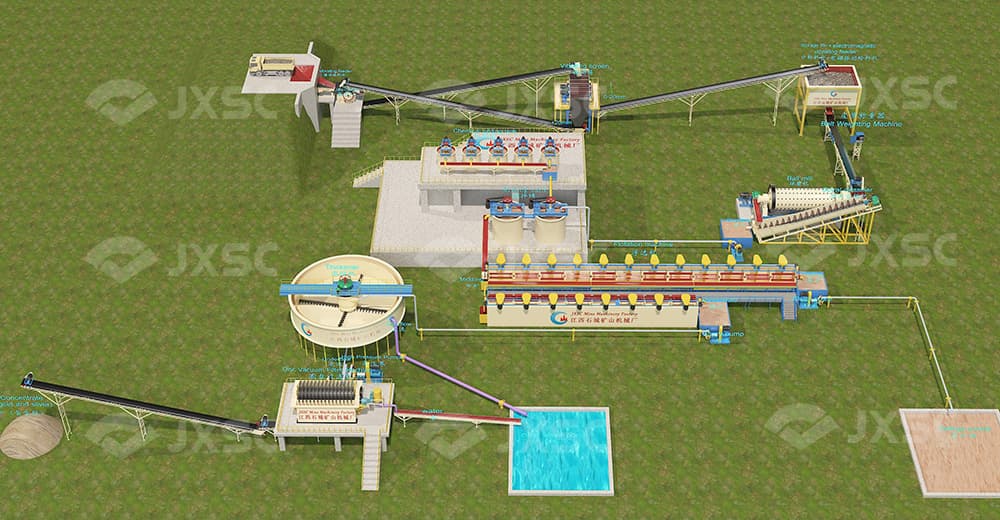

JXSC has 38 years of experience in the mining industry, and many experienced engineers provide professional technical support to customers. We focus on providing turnkey solutions and full equipment sales services for mining. Over the years, we have served hundreds of customers at home and abroad. Please send us your mining information. JXSC can provide more accurate suggestions based on your specific situation.