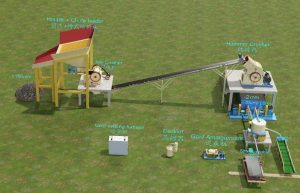

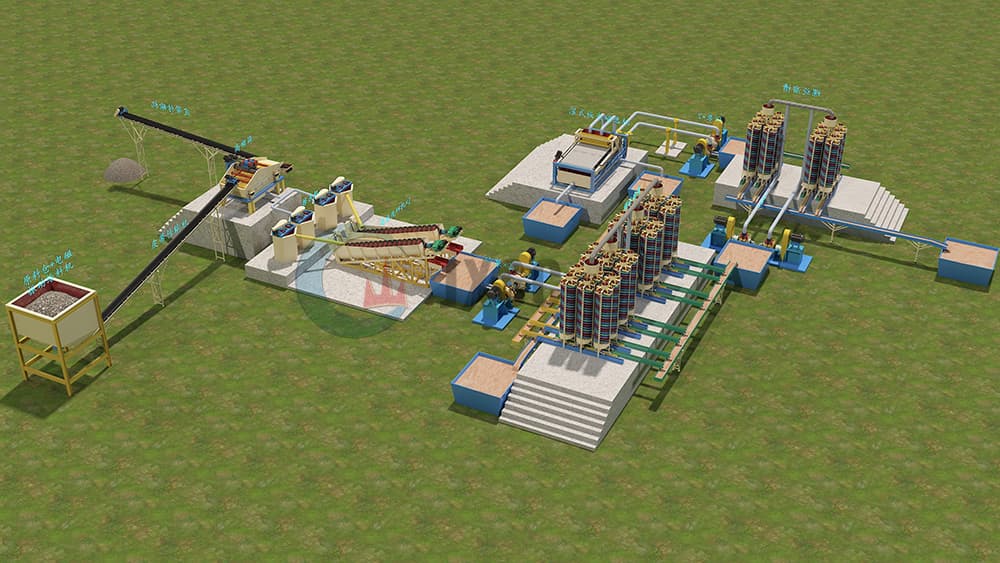

Quartz sand, also known as silica sand, is widely used in the glass and ceramic industries. Its main component is silicon dioxide. The purity of quartz sand directly affects its application effect. Therefore, in practical applications, it is often necessary to go through beneficiation treatment. Quartz sand beneficiation equipment includes crushers, ball mills, spiral classifiers, magnetic separators, flotation machines and concentrators, etc. These equipment together constitute a complete quartz sand beneficiation production line.

1. Crushing and screening

The first step in the beneficiation process is crushing. Through preliminary crushing and screening, larger impurities can be removed and the quartz ore can be crushed to a particle size suitable for subsequent processing.

2.Grinding and classification

After crushing, the quartz ore needs to be ground to refine its particle size further to adapt to the subsequent beneficiation process. Grinding usually uses a ball mill or a rod mill to grind the quartz ore to the required fineness. Classification uses equipment such as spiral classifiers or hydrocyclones to effectively separate particles of different particle sizes to prepare for subsequent beneficiation.

3. Ore dressing

After crushing and grinding, the quartz ore particles will be further converted into concentrates through ore dressing. The quartz sand beneficiation processes include washing, grading and desludging, scrubbing, magnetic separation, flotation and acid leaching.

Water washing and graded desludging: The quality of quartz sand decreases with the smaller particle size of the quartz ore, while the content of impurities such as iron and aluminum increases relatively, especially in quartz sand ore with high clay content. Therefore, water washing and graded desludging are necessary steps to improve the quality of quartz sand. This process can effectively remove clay and other fine impurities and improve the subsequent ore dressing efficiency.

Scrubbing: The scrubbing process mainly removes the iron film and other adherent impurities on the surface of quartz sand through the friction between mechanical force and quartz particles, and further crushes the quartz particles. Subsequently, the fine-grained particles are separated from the scrubbing slurry by a hydrocyclone to obtain higher-purity quartz sand.

Magnetic separation: The magnetic separation process is mainly used to remove weak magnetic impurities such as hematite, limonite, and biotite. Generally speaking, the separation of weak magnetic impurities usually uses a wet permanent magnetic drum magnetic separator, while the separation of strong magnetic substances uses a wet strong magnetic separator or a high gradient magnetic separator. These devices can effectively improve the purity of quartz sand.

Flotation: The flotation process is mainly used to remove impurities such as feldspar and mica in quartz sand. In industrial applications, hydrogen fluoride (HF) is often used as an activator, and under specific pH conditions, it is combined with a cationic collector for flotation separation.

Acid leaching: The acid leaching process uses the chemical properties of quartz sand for separation and purification. Quartz is almost insoluble in hydrochloric acid, sulfuric acid, and nitric acid, but can be dissolved by hydrogen fluoride (HF), so this property is widely used in the purification process of quartz sand. By controlling the acid-leaching conditions, impurities in quartz sand can be effectively removed, thereby improving its purity.

The quartz sand beneficiation process covers multiple links, including crushing, grinding, grading, scrubbing, magnetic separation, flotation, and acid leaching. Through the effective combination of these processes, high-purity quartz sand can be obtained. In actual production, it is also necessary to determine the specific mineral processing plan based on the properties of the original ore.

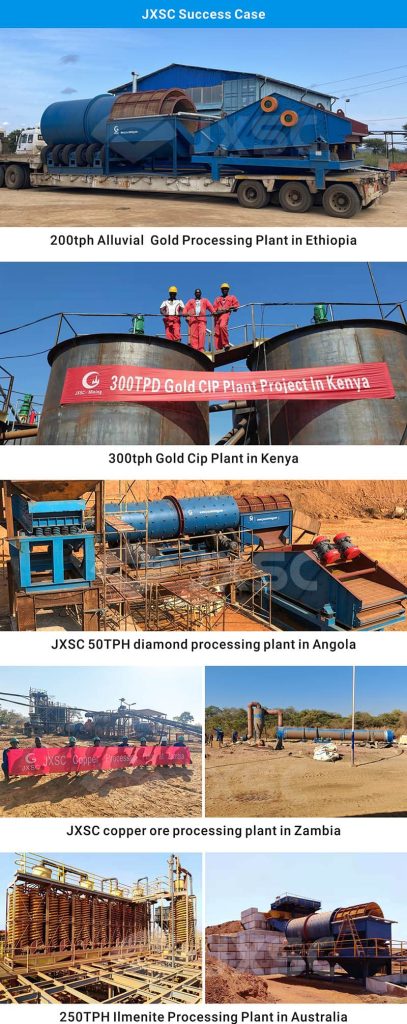

JXSC has 38 years of experience in the mining industry, and many experienced engineers provide professional technical support to customers. We focus on providing turnkey solutions and full equipment sales services for mining. Over the years, we have served hundreds of customers at home and abroad. Please send us your mining information. JXSC can provide more accurate suggestions based on your specific situation.