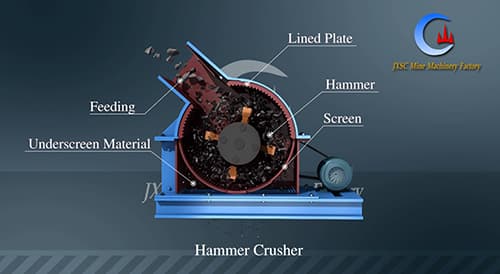

Hammer Crusher

It is suitable for crushing brittle materials with a compressive strength below 180MPa in industrial sectors such as cement, chemical industry, electric power, and metallurgy.

Capacity: 3-110 t/h

Applicable materials: limestone, slag, gypsum, coke, Medium and fine crushing of coal and other materials.

Description

Hammer crushers are divided into ordinary hammer crushers and ring hammer crushers. Ring hammers are generally suitable for coal, coke and other industries. Ordinary hammer crushers are usually represented by the English prefix PC, while ring hammer crushers are represented by the English prefix PCH. The hammer crusher has the characteristics of simple structure and large crushing ratio. It can be broken into shape at one time and can be used for dry crushing and wet crushing. At the same time, by adjusting the gap size of the grate bars, the particle size of the finished product can be changed.

Advantages

- The crushing ratio is large, the production efficiency is high, and the finished product has uniform particle size.

- High manganese steel hammer head, wear-resistant and impact-resistant.

- The gasket-type dischargThe hammer plate is equipped with a wear-resistant sheath to avoid direct collision between stones and the rotor plate, thereby extending the service life of the rotor.e port adjustment device makes the equipment highly adjustable.

- The sealing structure design of the crushing cavity solves the problems of dust pollution and dust leakage.

- The mobile hammer crusher can be customized to suit more scenarios.

Principle

During the hammer crushing operation, the motor drives the rotor to rotate at high speed, and the material enters the crushing chamber from the upper material opening, collides with the high-speed rotating rotor, and is crushed. The crushed materials fall to the sieve plate below, the materials smaller than the screen gap are discharged, and the materials larger than the screen gap continue to be crushed and ground by the hammer.

Specification

| Model | Feeding size (mm) | Discharge particle size (mm) | Capacity (t/h) | Power (kw) | Weight (t) | Overall dimensions of main body (L*W*H)MM |

| PC400*300 | <200 | <15 | 3-10 | 11 | 0.8 | 900*670*860 |

| PC600*400 | <250 | <15 | 10-20 | 22 | 2.2 | 1200*1050*1200 |

| PC800*600 | <250 | <25 | 20-50 | 55 | 4.8 | 1310*1180*1310 |

| PC1000*800 | <350 | <35 | 50-70 | 75-90 | 5.9 | 1600*1390*1580 |

| PC1000*1000 | <350 | <35 | 70-90 | 90-110 | 8 | 1800*1590*1775 |

| PC1200*1200 | <350 | <35 | 80-110 | 132-160 | 19.2 | 2060*1600*2200 |