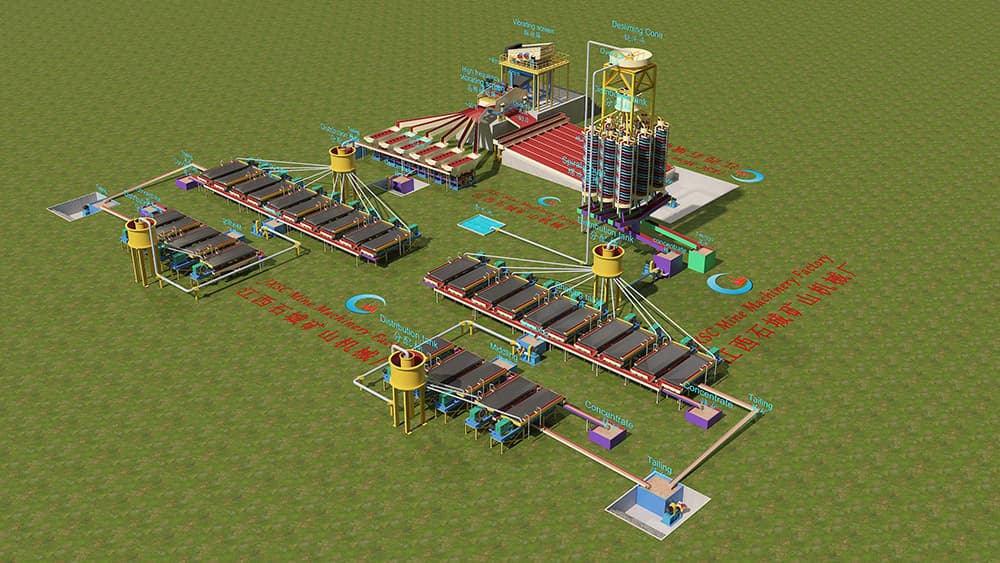

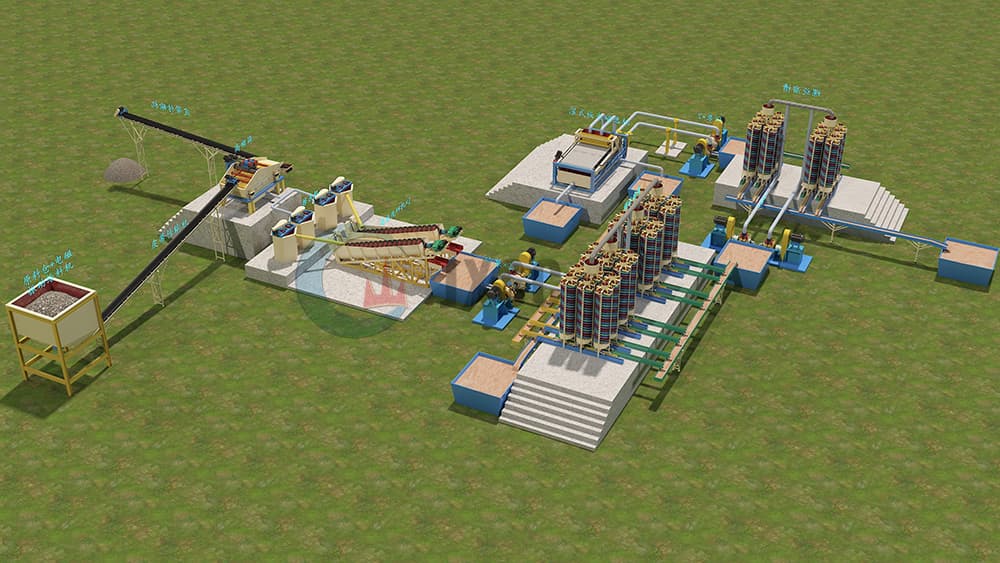

Exploring 100tph Ilmenite Processing Plant & Iron Ore Beneficiation

Iron ore is a key raw material for refining iron and is widely used in steel production. Ilmenite is an important source ore of iron. The main components of ilmenite are titanium oxide (TiO₂) and iron oxide (FeO), and its chemical formula is FeTiO₃. The ore is usually black or dark gray, has a metallic […]

Exploring 100tph Ilmenite Processing Plant & Iron Ore Beneficiation Read More »