How to Choose Between Ball Mill and Rod Mill

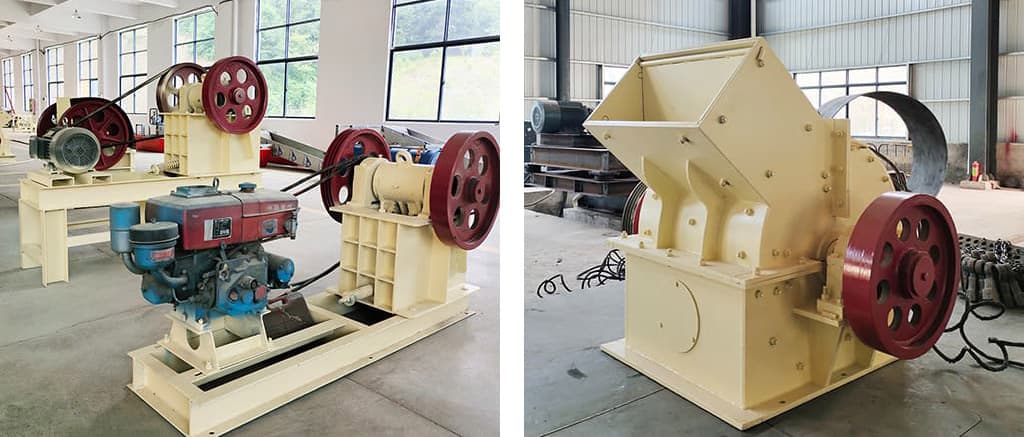

Choosing the right grinding equipment during mineral processing is crucial to improving mineral processing efficiency and mineral recovery rate. Ball mills and rod mills are commonly used in grinding processes. They look similar and work in the same principle, but there are still differences between them in actual use. Choosing the right mill according to […]

How to Choose Between Ball Mill and Rod Mill Read More »