What Are the Steps of Heavy Minerals Beneficiation in Beach Sand?

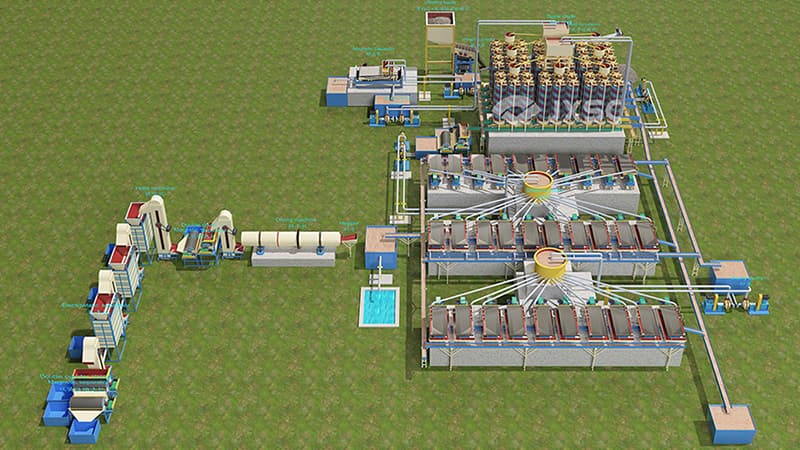

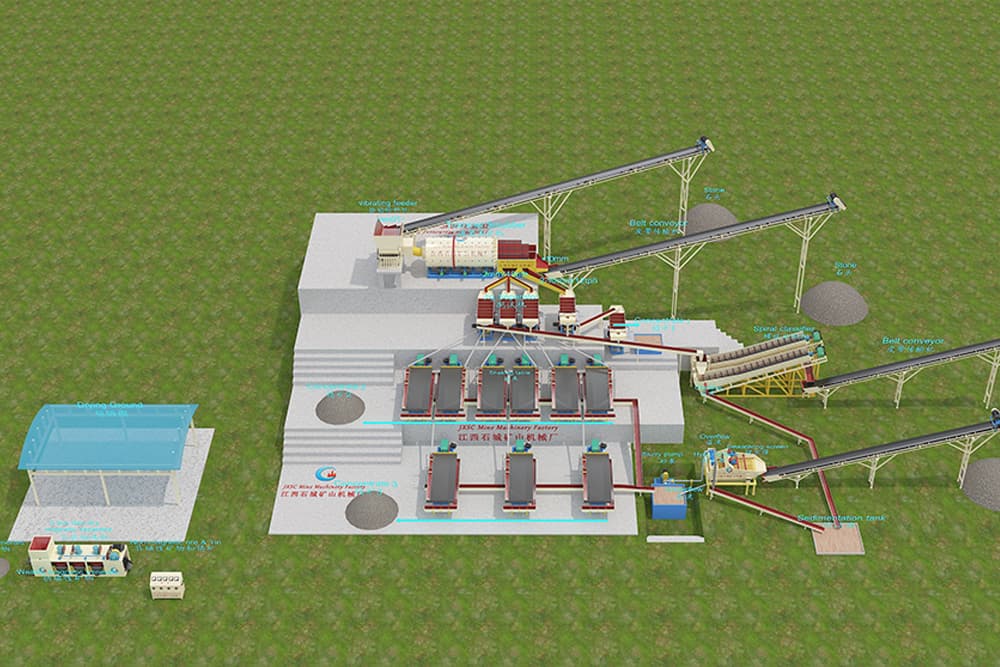

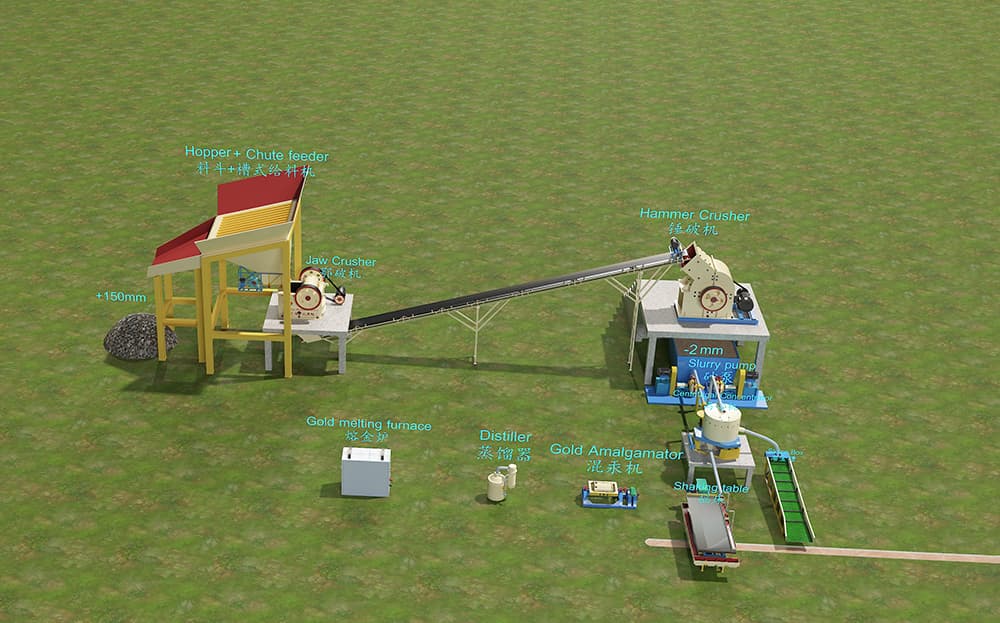

Beach sand deposits are sand deposits formed by waves and shore currents. Heavy mineral sands are washed up on the coast and deposited, while particles with small specific gravity and fine particle size are brought back to the sea. Beach sand contains rich rutile and zircon sand, which has important industrial value. Beach sand zircon […]

What Are the Steps of Heavy Minerals Beneficiation in Beach Sand? Read More »