Choosing the right grinding equipment during mineral processing is crucial to improving mineral processing efficiency and mineral recovery rate. Ball mills and rod mills are commonly used in grinding processes. They look similar and work in the same principle, but there are still differences between them in actual use. Choosing the right mill according to the properties of the mineral is crucial for mineral processing.

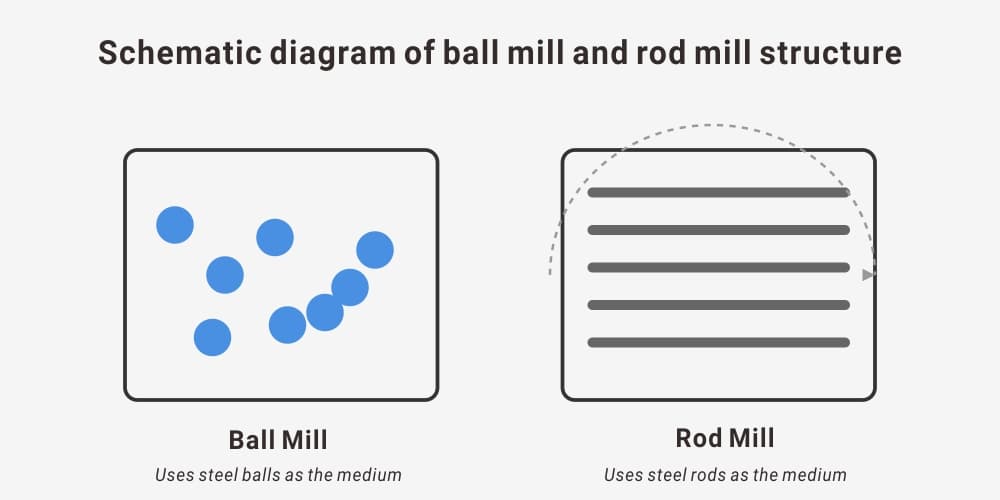

1. Differences in grinding media

Grinding media is the most intuitive feature that distinguishes the two types of equipment. Ball mills use steel balls or cast iron balls as grinding bodies. These grinding balls are spherical and can achieve multi-directional grinding effects. Rod mills use steel rods as grinding media. These steel rods are cylindrical and mainly grind in a linear direction.

2. Comparison of grinding effects

Ball mills can achieve a more delicate grinding effect, and the particle size of the final product can reach an extremely small level, which is particularly suitable for occasions that require ultra-fine grinding. However, the particle size distribution of the product after ball mill grinding is relatively wide. In contrast, the grinding of rod mill is relatively gentle. Although the particle size of the final product is relatively coarse, its particle size distribution is more concentrated and uniform, which can effectively avoid the problem of over-grinding, which makes it have unique advantages in occasions where medium particle size is required.

3. Analysis of working principle

The working process of ball mill reflects its diverse forms of movement. During operation, the steel balls can not only roll along the inner wall of the mill, but also be lifted and thrown freely. At the same time, the mutual collision between the balls is also constantly occurring. This complex combination of movements ensures a high grinding efficiency. The working method of rod mill is relatively simple. The steel rods mainly roll in a manner parallel to the axis of the mill, and rarely fall. The grinding effect mainly comes from the extrusion and shearing of the steel rods.

4. Comparison of application fields

Due to its excellent fine grinding ability, ball mills occupy an important position in the fields of mineral processing, cement production, ceramic manufacturing and chemical raw material processing, especially in the process of mineral processing that requires fine grinding. Rod mills play an important role in pre-grinding and building materials production in the mineral processing industry. Their uniform grinding characteristics make them an ideal choice for medium-sized material processing.

5. Economic Analysis

From the perspective of energy consumption, ball mills consume more energy because they need to lift the steel balls to a higher position. At the same time, the frequent collisions of steel balls cause rapid wear and tear, which requires regular replenishment, which also increases maintenance costs. Rod mills show better economic performance. The steel rods mainly perform rolling motion, which results in relatively small energy loss, slower wear, and more economical maintenance costs.

In the actual production process, it is also necessary to select the most suitable grinding equipment based on factors such as mineral properties and cost budget.

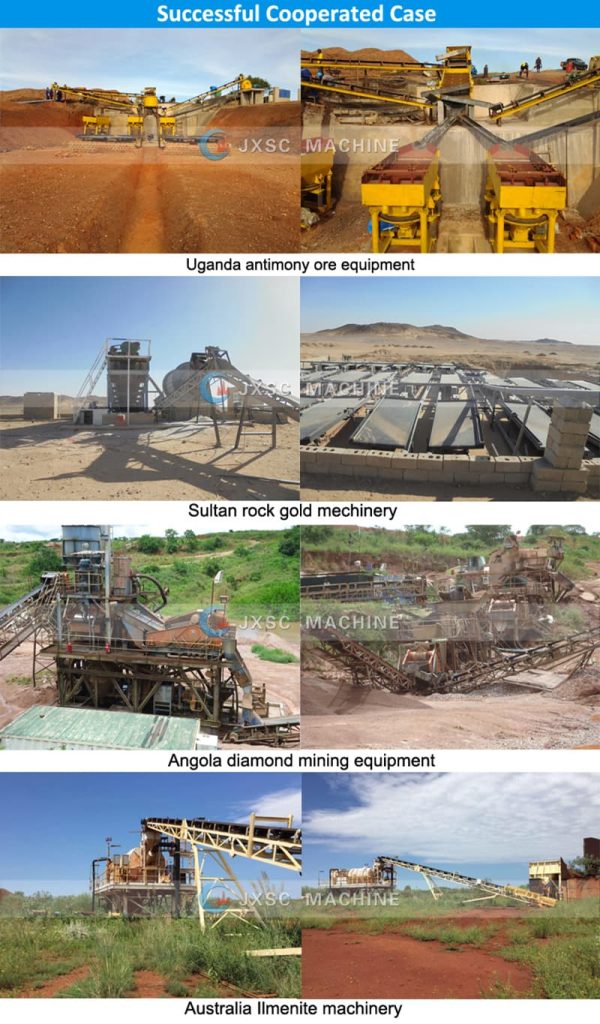

JXSC has 38 years of experience in the mining industry, and many experienced engineers provide professional technical support to customers. We focus on providing turnkey solutions and full equipment sales services for mining. Over the years, we have served hundreds of customers at home and abroad. Please send us your mining information. JXSC can provide more accurate suggestions based on your specific situation.