Fluorite, also known as fluorite, has a chemical composition of CaF2 and widely contains rare earth elements (such as Y, Ce) and other elements that can replace Ca (such as Fe, Al). Among them, yttrium-rich fluorite is called yttrium fluorite. Fluorite often coexists with quartz, calcite, barite and metal sulfide minerals. Because it contains fluorine, it is an important raw material for the preparation of fluorine-containing compounds. In addition, fluorite is widely used in industrial fields such as steelmaking, non-ferrous metal smelting, cement, glass and ceramics due to its low melting point. Transparent fluorite crystals can also be used in optics and handicrafts.

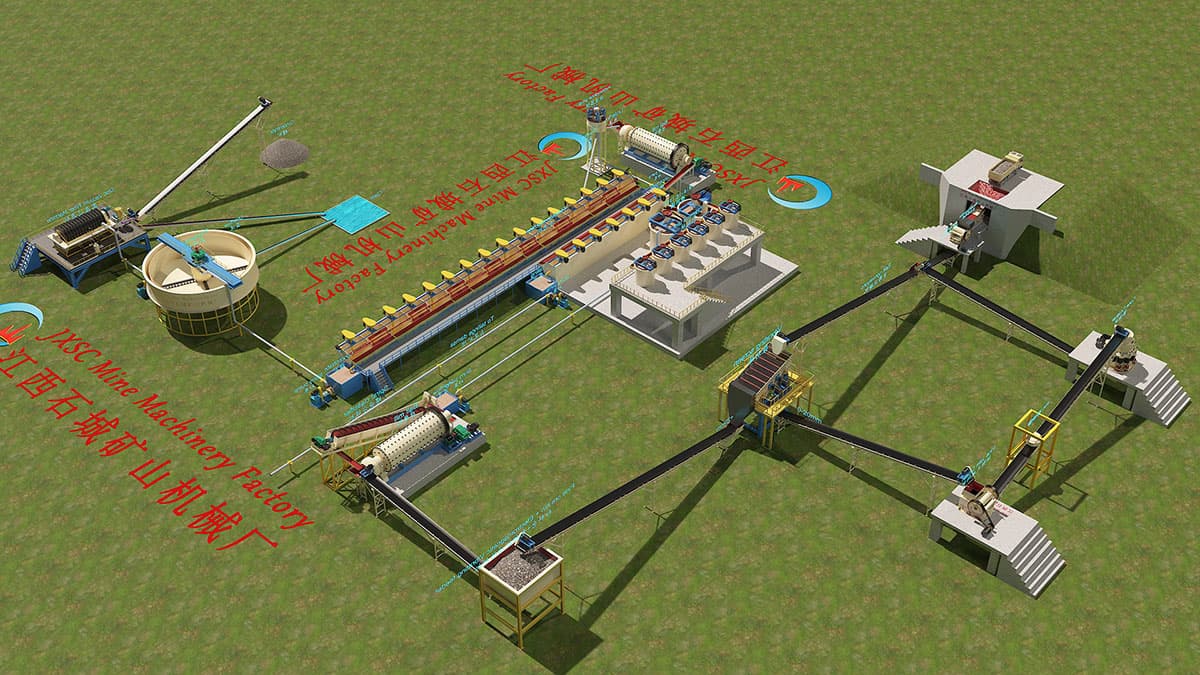

The fluorite beneficiation process mainly includes the following steps: ore crushing, grinding and grading, flotation sorting, roughing, scavenging and concentrating, concentration and dehydration, and tailings treatment.

1. Ore crushing

The first step in beneficiation is to crush the ore to reduce the particle size of the mineral and increase the exposed area of the mineral, laying the foundation for subsequent grinding and sorting operations. The crushing process is usually divided into three stages: coarse crushing, medium crushing and fine crushing. The purpose of coarse crushing is to initially crush the large pieces of mined materials into smaller sizes, usually using a jaw crusher. After coarse crushing, the materials enter the medium crushing stage to further reduce the particle size. Common equipment includes cone crushers and impact crushers. The last stage is the fine crushing stage, using an impact crusher or a roller crusher for final processing of the materials.

2.Grinding and classification

Grinding is the further processing of the crushed ore. Grinding operations usually use ball mills or rod mills. The ground minerals are classified by particle size through a spiral classifier or a hydrocyclone, and the coarse particles return to the grinding circuit, and the fine particles enter the sorting operation.

3. Flotation separator

Flotation is a key step in the beneficiation of fluorite ore. Through the action of flotation agents, fluorite minerals and gangue minerals are effectively separated. Flotation operations include the addition of adjusters, the addition of collectors, and the generation of bubbles. Anionic collectors such as oleic acid and its derivatives are usually used for the flotation of fluorite ore.

4. Roughing, scavenging and concentrating

In order to improve the grade and recovery rate of fluorite concentrate, flotation operations usually include three stages: roughing, scavenging and concentrating. Roughing is the preliminary sorting, scavenging is to further recover the valuable minerals in the tailings, and concentrating is the operation to improve the grade of the concentrate. According to the difference in the physical and chemical properties of the surface of fluorite and gangue minerals, the flotation of the minerals is changed by adding flotation agents to achieve the separation of fluorite and gangue. Commonly used flotation agents include collectors, inhibitors and frothers. Oleic acid, oxidized paraffin soap, etc. are often used as collectors for fluorite; water glass, sodium hexametaphosphate, etc. are used as inhibitors for gangue minerals.

5. Concentration and dehydration

The fluorite concentrate after sorting needs to be concentrated and dehydrated to meet the needs of subsequent processes or markets. Concentration operations usually use filters or centrifuges for dehydration operations.

6. Tailings treatment

Tailings are waste generated during the beneficiation process, and their treatment methods are crucial to environmental protection. Tailings treatment usually includes tailings concentration, dehydration and stockpiling. The rational use of tailings, such as for building materials or filling materials, is also an important way to achieve comprehensive resource utilization.

In the actual mineral processing process, due to the variety of fluorite ore types, the types and contents of other minerals contained are different, so it is very necessary to conduct mineral processing tests before determining the specific mineral processing process.

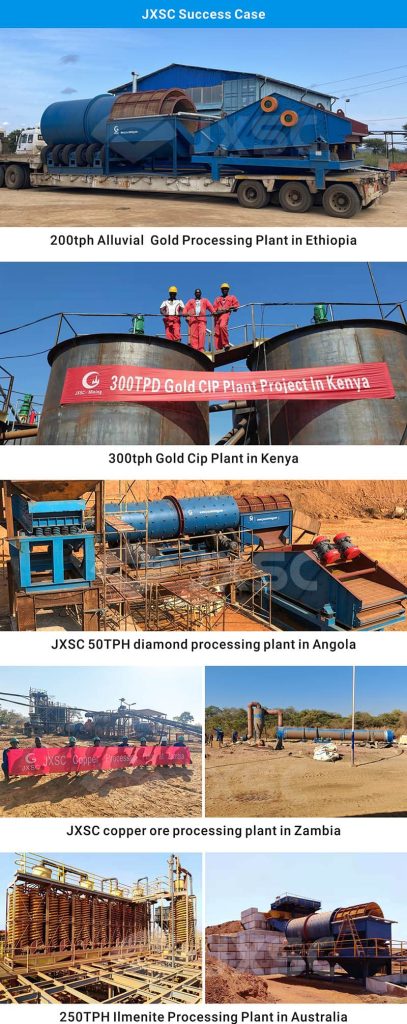

JXSC has 38 years of experience in the mining industry, and many experienced engineers provide professional technical support to customers. We focus on providing turnkey solutions and full equipment sales services for mining. Over the years, we have served hundreds of customers at home and abroad. Please send us your mining information. JXSC can provide more accurate suggestions based on your specific situation.