Copper ore has significant sulfur affinity and mainly occurs in the form of sulfide. Copper oxide will also be formed under strong oxygen conditions.

The beneficiation of copper ore mainly uses flotation, sometimes combined with magnetic separation, gravity separation or hydrometallurgy. The mineral processing process is selected based on the specific physical and chemical properties of the raw ore, associated minerals, etc.

The natural types of copper ores are generally divided into sulfide ores (containing less than 10% copper oxide), mixed ores (containing 10 to 30% copper oxide) and oxidized ores (containing 10% to 30% copper oxide) according to the different proportions of copper oxide and copper sulfide. Copper (copper above 30%) three types. The commonly used beneficiation processes for different types of copper ores are as follows:

1. Single copper sulfide: generally beneficiated by flotation.

2. Polymetallic copper sulfide: According to its main components, you can choose the mixed flotation method, the preferential flotation method, the mixed preferential flotation method, the flotation and gravity separation combined beneficiation method, the flotation and magnetic separation combined beneficiation method, and the flotation beneficiation method. Processing combined with selection and hydrometallurgy, etc.

3. Mixed copper: Generally, flotation is used, which can be treated alone or together with sulfide ore; flotation and hydrometallurgy can also be used together, that is, the copper concentrate is first selected by flotation, and then the flotation The final tailings are treated by hydrometallurgy.

4. Copper oxide: generally treated by a combination of flotation and hydrometallurgy or a combination of segregation and flotation; ores containing high levels of combined copper oxide are generally treated by hydrometallurgy.

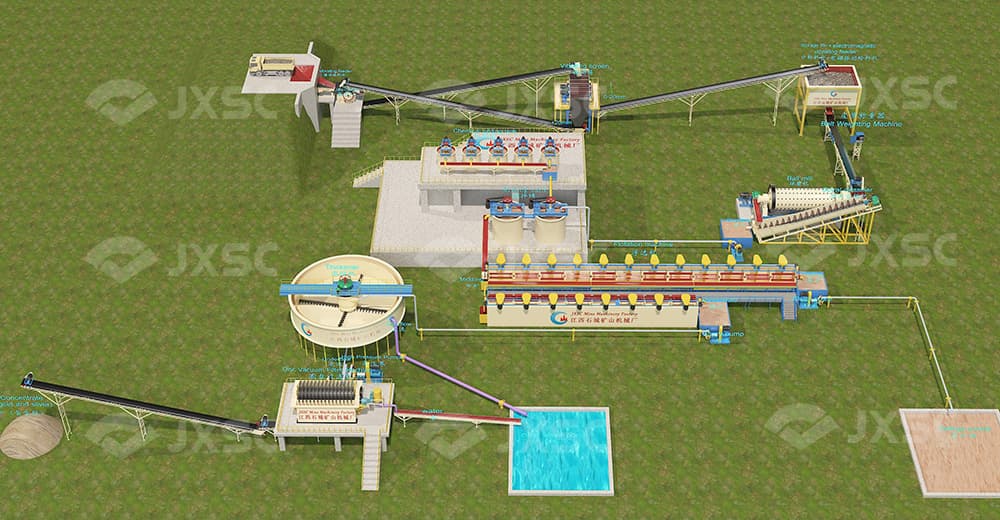

The specific beneficiation process of copper ore is as follows.

1. Crushing and screening

After mining, copper ore needs to be crushed to a certain particle size using crushing equipment to meet the feed particle size requirements for subsequent grinding operations. Two-stage one-closed-circuit crushing and three-stage one-closed-circuit crushing are commonly used crushing processes, including four parts: coarse crushing, medium crushing, fine crushing and screening. Screening and the final crushing section form a closed circuit to ensure the crushing particle size of the ore.

2.Grinding

One-stage closed-circuit grinding and two-stage closed-circuit grinding are both common methods in the grinding process. Usually a ball mill is used, combined with a spiral classifier to form a closed circuit.

3. Mineral processing

Copper sulfide mineral processing

(1) Multi-stage flotation process

The multi-stage flotation method is a conventional copper sulfide ore flotation method, which focuses on the separation of copper and sulfur. Generally, a closed-circuit flotation process of multi-stage rough selection-multi-stage selection-sweeping is used. Suitable for selecting simple copper sulfide minerals.

(2) Step-by-step priority flotation process

Distribution priority flotation is used for more complex copper sulfide ores, mainly azurite and sulfur-arsenic copper ores. Due to its complex structure, the conventional flotation process cannot obtain qualified copper concentrate. Therefore, it is necessary to roughly select the copper minerals that are easy to float, and then regrind the copper minerals that are difficult to float, re-select the middlings, and combine them for recycling. Copper concentrate.

(3) Flotation – mixed concentrate separation process

This method is suitable for lower-grade copper ores or copper sulfide ores with complex symbiotic relationships among chalcopyrite, sphalerite and galena. Generally, a large amount of gangue minerals are discarded through rough grinding and rough selection to obtain a mixed concentrate of copper, lead and zinc, and then the copper, lead and zinc concentrate is separated to obtain a single copper mineral.

(4) Waiting for flotation process

The equal flotation method is to divide the minerals with fast floating speed and slow floating speed into two parts for flotation respectively. This process can eliminate the impact of residual chemicals on flotation separation, uses less chemicals, and has good sorting indicators. However, the process is more complex, takes a long time, and requires more grinding equipment to be used in conjunction.

Copper oxide mineral processing

(1) Direct flotation process

Direct flotation method refers to the direct flotation of minerals without prior sulfidation. It is mostly used for ores with simple gangue composition.

(2) Sulfide flotation process

This method mainly uses soluble sulfides such as sodium sulfide and sodium hydrosulfide to pre-sulfide copper minerals, and then use copper sulfide collectors for recovery.

(3) Acid leaching process

This method mostly uses dilute sulfuric acid as the leaching agent. The copper minerals are leached into the leachate through heap leaching, pool leaching, in-situ leaching, stirring leaching, etc., and then the copper is removed from the leachate using methods such as displacement, precipitation, extraction-electrowinning, etc. extracted from. Mainly suitable for ores containing acidic gangue.

(4) Ammonia leaching process

This method uses the principle that ammonia reacts slowly with copper minerals in ores to form copper-ammonia complexes to recover copper minerals. Mainly suitable for copper oxide ores containing a large amount of alkaline gangue minerals and slime.

(5)Separation-flotation process

This method is to send the ore crushed to a certain particle size, 2~3% coal powder and 0.5~1% salt into the roasting furnace, and perform high-temperature roasting in a neutral or reducing atmosphere. During the process, the copper oxide minerals are It is reduced to metallic copper and precipitated on the surface of coal particles.

(6) Flotation-leaching combined separation process

Common flotation-leaching combined beneficiation methods include ammonia leaching sulfide flotation, acid leaching-precipitation-carrier flotation, stirring leaching-iron replacement-flotation, etc. This type of combined beneficiation is mainly suitable for refractory copper oxide. ore.

For the specific selection of ore beneficiation methods, it is also necessary to determine the ore properties through beneficiation tests.

JXSC has 38 years of experience in the mining industry, and many experienced engineers provide professional technical support to customers. We focus on providing turnkey solutions and full equipment sales services for mining. Over the years, we have served hundreds of customers at home and abroad. Please send us your mining information. JXSC can provide more accurate suggestions based on your specific situation.