Tantalum-niobium ore is a complex type of ore, containing a variety of valuable metal minerals, such as tantalum-niobium ore, coltan, tantalum-niobium-tin, columbite, etc. The separation and extraction of these minerals is critical to the production of tantalum and niobium metals.

The beneficiation of tantalum-niobium ore usually uses a combination of multiple processes, including crushing, washing, gravity separation, magnetic separation and flotation.

1. Crush and Washing

Before sorting, it must first be pre-treated according to the mineral properties to facilitate subsequent mineral processing.

When processing tantalum-niobium rock ore, the raw ore first needs to be crushed and finely grinding to release the mineral particles.

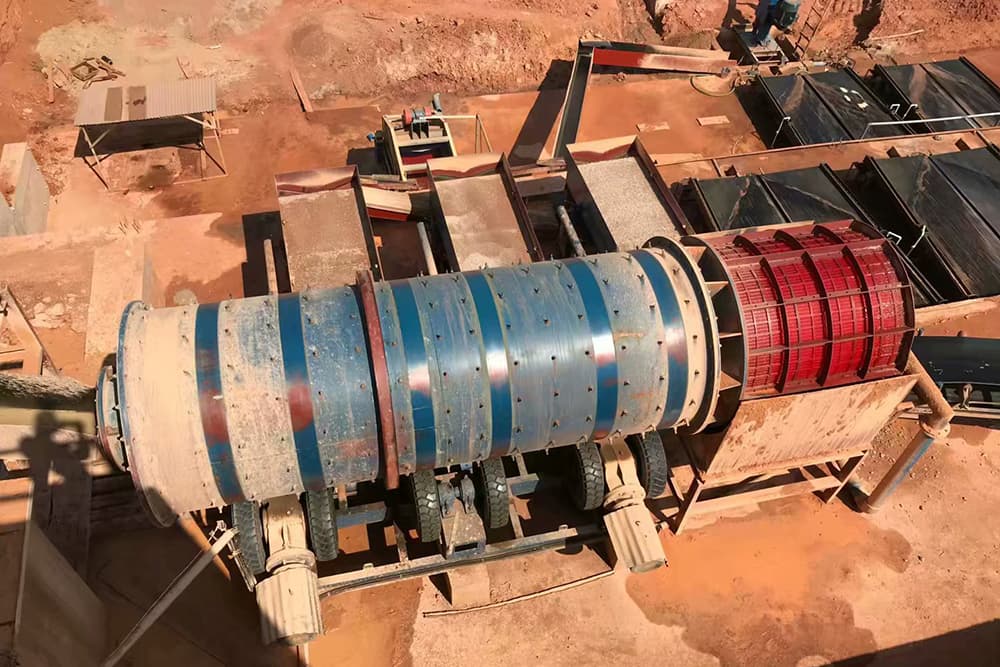

For tantalum-niobium sand deposits with high mud content, ore washing operations are crucial. Rotary scrubber is usually used for the ore washing process. Through cleaning, soil impurities in the tantalum-niobium ore can be effectively removed to facilitate subsequent mineral processing.

2. Gravity Separation, Magnetic Separation and Flotation.

The gravity separation process is the main means of roughing tantalum-niobium ore, which can efficiently separate mixed coarse concentrates containing valuable minerals such as tantalum-niobium, tungsten, and tin. Roughing plants usually use a variety of gravity separation equipment such as jig separator, spiral chutes, shaking tables and centrifugal concentrator for separation. The gravity separation method is pollution-free and low-cost, but the separation and recovery rate of sludge is low.

This coarse concentrate then enters the concentration stage, where it can be further separated and purified using magnetic separation, flotation and other methods. Dry three-disk magnetic separators are commonly used for magnetic separation, which is very effective for tantalum-niobium ores containing magnetic minerals. Before magnetic separation, it is sometimes necessary to combine chemical treatments such as pickling to remove the influence of surface iron and improve the separation efficiency. Flotation is suitable for processing tantalum-niobium ore slime, reducing the loss of tantalum-niobium ore and improving the grade of concentrate.

Different types of tantalum-niobium ores have different compositions and characteristics, and the mineral processing process will be adjusted accordingly. For example, for primary tantalum-niobium ore and fine crystals, a multi-stage gravity separation process is usually used; for tantalite-columbite sand ore, a combined process of magnetic separation and electric separation is more often used. In addition, yellow-green tantalum and niobium deposits adopt a combined process of gravity separation, magnetic separation and flotation according to the type of ore.

In general, the determination of the tantalum-niobium ore beneficiation process is mainly based on the properties of the raw ore, including the density, hardness, magnetism of various minerals in the ore, the embedded particle size and occurrence state of useful minerals. Through the comprehensive utilization of crushing, washing and screening, gravity separation, magnetic separation, flotation and other means, valuable metals such as tantalum and niobium can be effectively recovered and separated.