Tantalum and niobium are indispensable rare metals in modern industry and are widely used in electronics, aerospace and nuclear industries. In nature, these two elements often appear together and coexist with other minerals such as tin and iron. Due to the large specific gravity of tantalum-niobium ore, the beneficiation process of tantalum-niobium sand ore mainly relies on gravity separation. This article will introduce the efficient beneficiation process from ore to concentrate in detail.

Washing and screening

Tantalum-niobium sand ore has a high monomer dissociation degree and usually does not require crushing. However, the ore often contains slime, which may affect the subsequent beneficiation effect. Therefore, the first step is to use a rotary scrubber for washing and desliming. This equipment can not only effectively remove clay, but also screen and remove large particles of gangue at the same time. If washing is not required, trommel screen can be used for screening. Improve the efficiency of subsequent gravity separation and ensure the quality of feed.

Gravity separation treatment

Gravity separation is the core link of tantalum-niobium ore separation, which mainly depends on the density difference between minerals. Commonly used equipment includes Jig separator, shaking table and spiral chute. The processing flow varies according to the characteristics and output of the ore:

Large processing volume or uneven particle size ore: Jig separator primary selection → shaking table selection

Fine particle size ore: spiral chute primary selection → shaking table selection

Small processing volume: directly use shaking table for ore selection.

This flexible configuration can adapt to different types of tantalum-niobium sand ores, optimize sorting efficiency and improve concentrate grade.

Iron mineral separation

Tantalum-niobium ore often contains some iron minerals, such as magnetite and ilmenite. In order to improve the grade of tantalum-niobium ore, the concentrate is magnetically separated after gravity separation to remove magnetic minerals. This step often uses a three-disc magnetic separator with strong magnetism to effectively remove iron minerals.

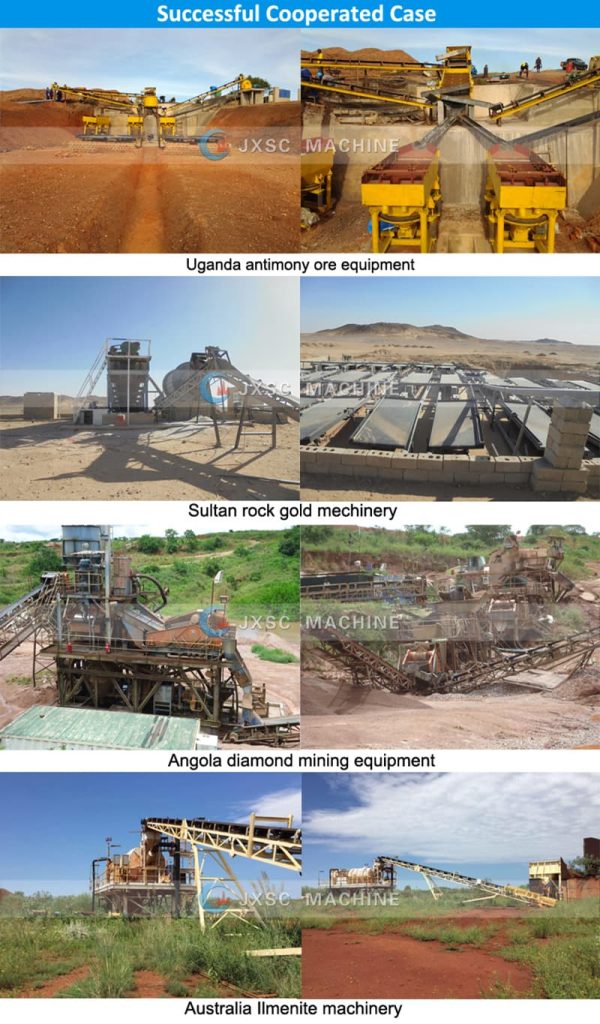

JXSC has 38 years of experience in the mining industry, and many experienced engineers provide professional technical support to customers. We focus on providing mineral turnkey solutions and full equipment sales services. We have served hundreds of customers at home and abroad over the years. Please send us your mineral mining information. A technician will contact you immediately.