In the current global mining market, the strategic position of gold is self-evident. As easy-to-mine gold ore resources are dwindling, the efficient development and utilization of low-grade, complex gold ores has become a focus and difficulty in the industry. This article aims to deeply explore the technical details, application conditions and optimization directions of modern gold ore beneficiation processes, and provide a comprehensive professional reference for engineers and technicians engaged in gold mine development.

Occurrence characteristics of gold and mineral processing principles

The form of gold in the ore directly affects the choice of mineral processing technology. Mainly include:

1. Alluvial gold

2. Rock gold

3. Mineralized gold such as gold sulfide

Gold in different occurrence states has significant differences in its degree of dissociation and selectivity, which determines the complexity and recovery efficiency of the mineral processing process. Understanding the occurrence characteristics of gold is the basis for selecting and optimizing mineral processing processes.

Main gold selection processes and their technical analysis

1. Gravity beneficiation

Gravity beneficiation uses the density difference between gold and gangue minerals (gold density is about 19.3g/cm³) to separate.

key equipment

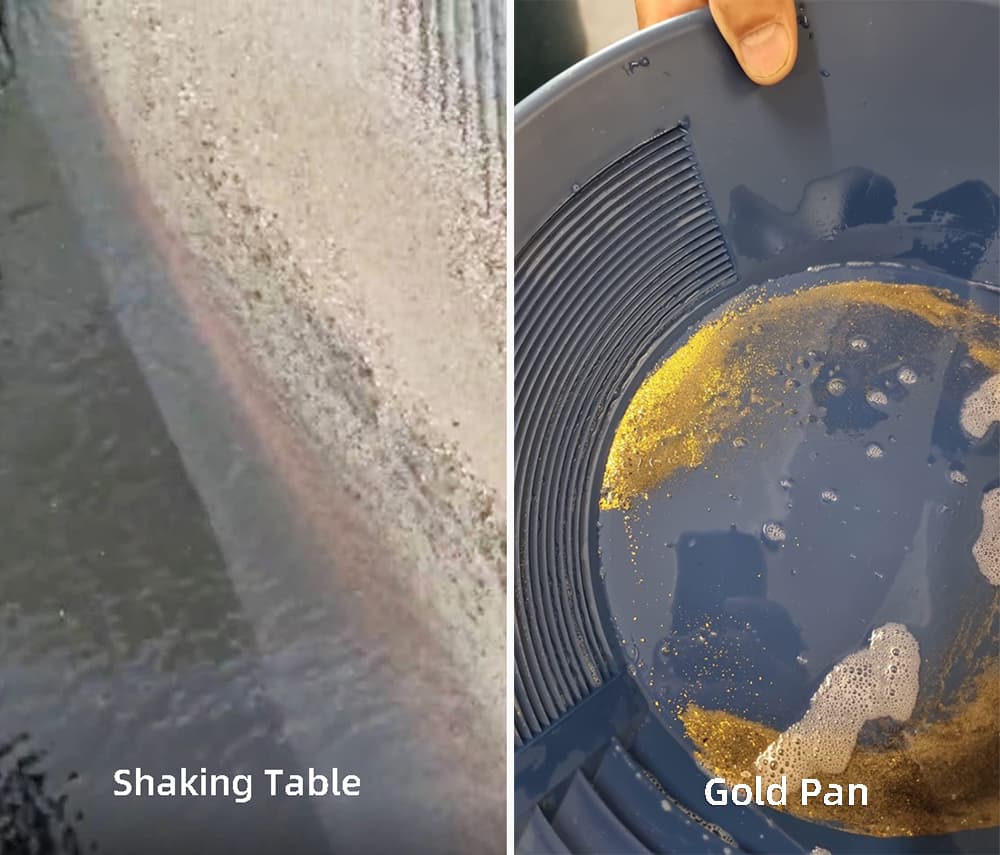

– shaker table

– Centrifugal Concentrator

– Spiral chute

– Jig machine

Applicable conditions

– High content of coarse gold (>74μm)

– High gold to silver ratio

Advantages and Disadvantages

Advantages: simple process, low operating cost

Disadvantages: low recovery rate for fine-grained gold (<74μm)

Process analysis

The gravity beneficiation process can be broken down into the following key steps:

1. Crushing and screening: crush the raw ore to appropriate particle size (usually <2mm) and screen to remove excessively fine particles.

2. Pre-selection: Use a shaking table or spiral chute for preliminary enrichment to remove most of the light gangue.

3. Selection: The pre-selected product is further processed, usually using a centrifuge or jig.

4. Concentrate processing: Gravity concentrate can be directly smelted or used as feed material for other processes (such as flotation).

The effect of gravity beneficiation is affected by factors such as the dissociation degree of the ore, the particle size distribution of the feed ore, and equipment parameters (such as shaker inclination angle and centrifuge speed). Optimizing these parameters can significantly improve the sorting effect.

2. Flotation separator

The flotation method utilizes the sulfur affinity of gold and sulfide minerals to achieve selective separation by adjusting the flotation reagent system.

key potion

– Collecting agents: xanthate, ethionate

– Foaming agent: terpineol, methyl isobutyl ketone (MIBK)

– Adjuster: sodium carbonate, copper sulfate

Applicable conditions

– Gold and sulfide minerals are closely embedded

– High content of fine gold

Advantages and Disadvantages Analysis

Advantages: Suitable for processing complex and refractory gold mines

Disadvantages: The cost of chemicals is high and the impact on the environment needs to be strictly controlled.

Process analysis

The specific process flow of flotation usually includes:

1. Ore grinding: Grind the ore until it is fine enough (usually -200 mesh accounts for 70-80%) to fully dissociate gold and gold-bearing minerals.

2. Slurry adjustment: Adjust the pulp concentration (usually 25-35% solids), and add adjusters to adjust the pH value.

3. Rough separation: Add collector and foaming agent to carry out the first stage of flotation to obtain coarse concentrate.

4. Scavenging: Scavenging the roughing tailings to recover the remaining valuable minerals.

5. Selection: The coarse concentrate is selected multiple times to improve the concentrate grade.

6. Purification: remove impurity minerals in the concentrate, such as chalcopyrite, galena, etc.

The flotation effect is highly dependent on the selection and dosage control of the chemical system. Different types of gold ore may require specific combinations of agents, such as arsenic gold ores that may require an activator (such as copper sulfate) to improve recovery.

3. Cyanide leaching method

The cyanide leaching method uses cyanide to dissolve gold under alkaline conditions to form a soluble gold cyanide complex.

Process variant

– CCD (carbon adsorption-direct cyanidation)

– CCF (Counter Current Wash Cyanide)

– CIP (carbon pulp method)

– CIL (carbon leaching method)

Applicable conditions

– Oxidized gold deposits

– Refractory metallurgical ores

Advantages and Disadvantages Analysis

Advantages: high recovery rate, wide application range

Disadvantages: High environmental risks, requiring strict safety management

Process analysis

The specific process flow of the cyanide leaching method can be divided into the following main stages:

1. Preprocessing:

– Pickling: removes carbonate minerals and reduces cyanide consumption.

– Pre-oxidation: For sulfide-containing ores, pre-oxidation may be required.

2. Cyanide leaching:

– Stirred leaching: carried out in large stirred tanks, usually lasting 24-72 hours.

– Heap leaching: suitable for low-grade ores, longer cycle (weeks to months).

3. Solid-liquid separation:

– CCD method: Use multi-stage countercurrent washing thickener.

– Press filter method: suitable for certain ores that are difficult to process.

4. Gold recycling:

– Zinc powder replacement: traditional method, suitable for high-grade solutions.

– Activated carbon adsorption: including CIP and CIL processes, more suitable for processing low-grade solutions.

5. Desorption electrolysis: Desorption of gold from gold-loaded activated carbon, and then electrolysis recovery.

6. Refining: Smelting the electrolytic products to make gold ingots.

The key to the cyanidation process is to optimize parameters such as cyanide concentration, pH value, and dissolved oxygen content in the solution to maximize the rate and extent of gold dissolution.

The above are several common methods for extracting gold from ore. No matter which method is used, various factors such as ore characteristics, technical feasibility, economic benefits and environmental impact must be comprehensively considered. It is recommended that you conduct a mineral processing test first, and then design a suitable gold ore extraction process based on the test analysis.

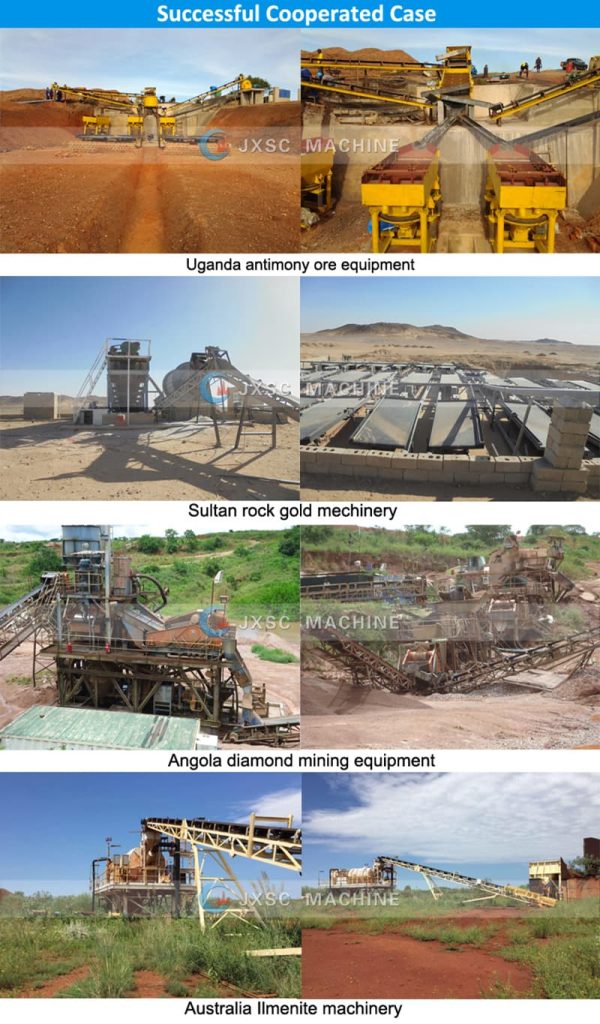

JXSC has 38 years of experience in the mining industry, and many experienced engineers provide professional technical support to customers. We focus on providing turnkey solutions and full equipment sales services for mining. Over the years, we have served hundreds of customers at home and abroad. Please send us your mining information. JXSC can provide more accurate suggestions based on your specific situation.