The gold element in oxidized gold ore mainly exists in the form of oxide or hydroxide. The gold element of the ore is closely combined with the oxidized minerals, and the ore structure is complex and difficult to extract directly. Therefore, the heap leaching process came into being, providing an economical and efficient beneficiation solution for small and medium-sized gold mines. The heap leaching process is a beneficiation method for low-grade oxidized gold ore. Its core idea is to pile up the ore on a special bottom pad, use a low-concentration alkaline solvent to continuously spray, dissolve the gold element in the ore, and achieve metal recovery through professional equipment.

The entire heap leaching gold selection process mainly includes key links such as ore accumulation, solution spraying, metal dissolution, metal recovery and tailings treatment. In the ore accumulation stage, the ore needs to be evenly piled on the anti-seepage bottom pad; by using sodium cyanide and other solvents for repeated leaching, the gold element is dissolved and collected; finally, the metal is extracted by activated carbon adsorption, replacement and other methods, and the ore slag after the reaction is harmlessly treated.

The heap leaching process mainly includes three common methods: zinc powder replacement method, carbon adsorption method and ion exchange adsorption method.

The zinc powder replacement method is suitable for gold-containing precious liquid after cyanide leaching. It mainly uses zinc powder or zinc wire as a reducing agent. Its process includes washing, leaching liquid purification, deoxidation and replacement.

The technical advantage of the carbon adsorption method is that it does not require additional filtering devices and can directly adsorb gold elements in the cyanide slurry.

The ion exchange adsorption method is based on the double decomposition reaction of the target ions in the solution and the solid exchange agent to achieve the selective transfer of the target components between the liquid phase and the solid phase.

In order to ensure the efficient operation of the heap leaching process, a variety of professional equipment is required. These equipment include crushing equipment (such as jaw and cone crushers), screening equipment (vibrating screening), solution treatment equipment (adsorption column, barren liquid tank and barren liquid pump, precious liquid tank, carbon storage tank, analytical column), metal extraction equipment (electrolyzer, desorption liquid tank, zinc powder feeder) and auxiliary equipment (air compressor, circulating pump, filter press, slurry pump).

In practical applications, the optimization of mineral processing schemes is crucial. It is recommended to customize exclusive process solutions according to the characteristics of the ore, conduct sufficient mineral processing tests, continuously optimize process parameters, and pay attention to environmental protection and comprehensive resource utilization. Through precise process design and advanced equipment support, we can significantly improve the economic value of low-grade ores and promote the efficient utilization of mineral resources.

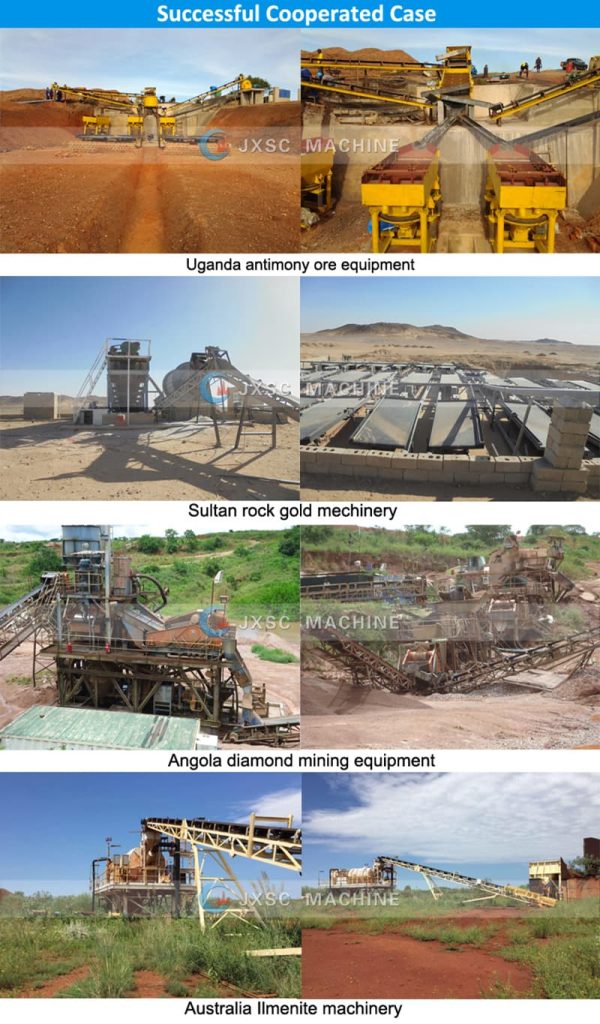

JXSC has 38 years of experience in the mining industry, and many experienced engineers provide professional technical support to customers. We focus on providing turnkey solutions and full equipment sales services for mining. Over the years, we have served hundreds of customers at home and abroad. Please send us your mining information. JXSC can provide more accurate suggestions based on your specific situation.