Chrome has excellent properties such as hardness, brittleness and corrosion resistance, so it is widely used in metallurgy, chemical industry, cast iron, refractory and high-precision technology.

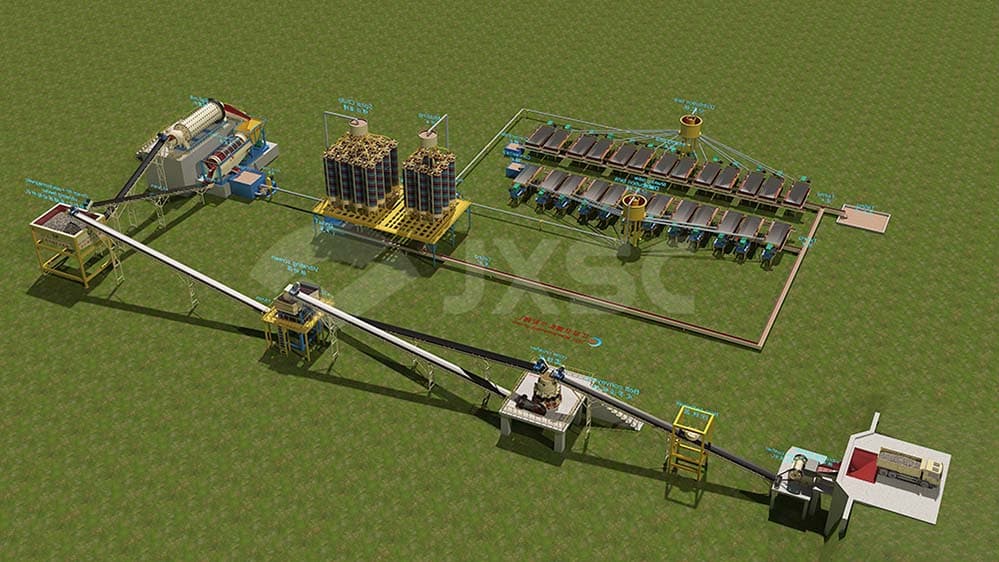

Chrome has a strong affinity for iron. In nature, chrome and iron always coexist, and chrome ore is often called chromite. Chrome ore processing plants usually include four systems: crushing, grinding, beneficiation, and dehydration. After these processes, high-quality chrome concentrate can be obtained.

1. Crushing system

Crushing and grinding of raw ore are the starting point of the entire chrome ore beneficiation process. First, the large pieces of raw ore are broken into small pieces by a crusher for subsequent grinding operations. This step often uses jaw crushers, hammer crushers, and cone crushers.

2. Grinding system

The crushed ore is sent to a ball mill or a rod mill to further grind the coarsely crushed ore to meet the particle size requirements of beneficiation.

3. Ore beneficiation system

Gravity separation: Gravity separation is a common treatment process for chrome ore, which uses the density difference between chrome ore and gangue to separate gangue. Gravity separation equipment includes jig separator, shaking table and spiral chute. Jig separator is suitable for processing coarse-grained chromite, while shaking table and spiral chute are suitable for processing fine-grained chromite.

Magnetic separation: Gravity separation cannot separate some magnetic heavy minerals such as iron, so magnetic separators are used to separate magnetic minerals from tin concentrate to improve the grade of chromite concentrate. Both weak magnetic and strong magnetic separators can separate chromite.

In a weak magnetic field, the grade of chromite concentrate is improved by removing strong magnetic minerals (mainly magnetite) from the ore;

In a strong magnetic field, gangue minerals are separated and chromite is recovered.

Flotation: Gravity separation and magnetic separation are both difficult to obtain good separation effects for fine-grained chromite, so flotation is a good supplement. Add flotation reagents to the flotation machine to process fine or fine-grained chromite, but attention should be paid to the selection and dosage of reagents.

4. Dehydration system

The chrome concentrate obtained from mineral processing sometimes contains a lot of water, and concentrators and filters are often used for dehydration.

When selecting chrome ore beneficiation technology and equipment, you can refer to the mineral processing test indicators. The specific process flow should be determined according to the properties of the ore itself. Adopting appropriate process flow and equipment configuration can reduce costs and improve economic benefits.

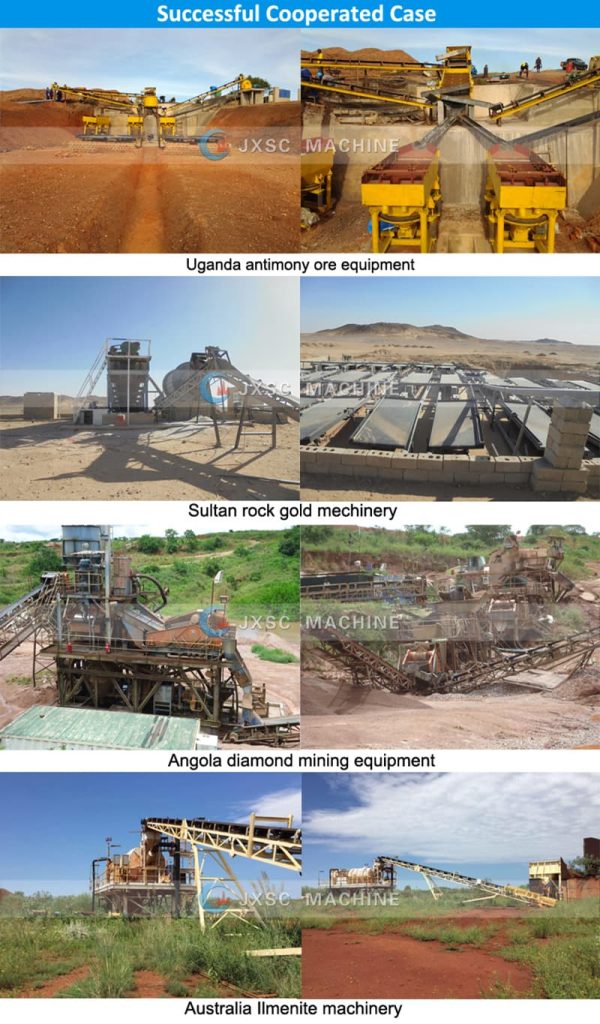

JXSC has a large number of authoritative mining industry technicians, has accumulated rich experience in mining research, machinery development, and mineral processing, has mastered the mining and beneficiation technology of more than 70 ores, and has design and mining experience in hundreds of mines. Welcome to consult and visit our factory.