The specific gravity of tin ore is 6.8-7.1, and the crystal belongs to the tetragonal system, often accompanied by iron, tantalum, niobium and other minerals. Tin is soft and ductile, chemically stable, corrosion-resistant, fusible, has a low friction coefficient, and tin salts are non-toxic. Therefore, tin and tin alloys have been widely used in modern national defense, modern industry, cutting-edge science and technology, and human life.

Alluvial tin ore is formed by long-term weathering and deposition of rock ore, and contains sticky clay. Therefore, the alluvial tin ore must be cleaned and separated before beneficiation. Because cassiterite has a large specific gravity and a significant difference in specific gravity with gangue, gravity separation is often used in the beneficiation process. Sometimes there are iron oxide minerals in the ore, and magnetic separation and flotation are used to increase the purity of the tin concentrate.

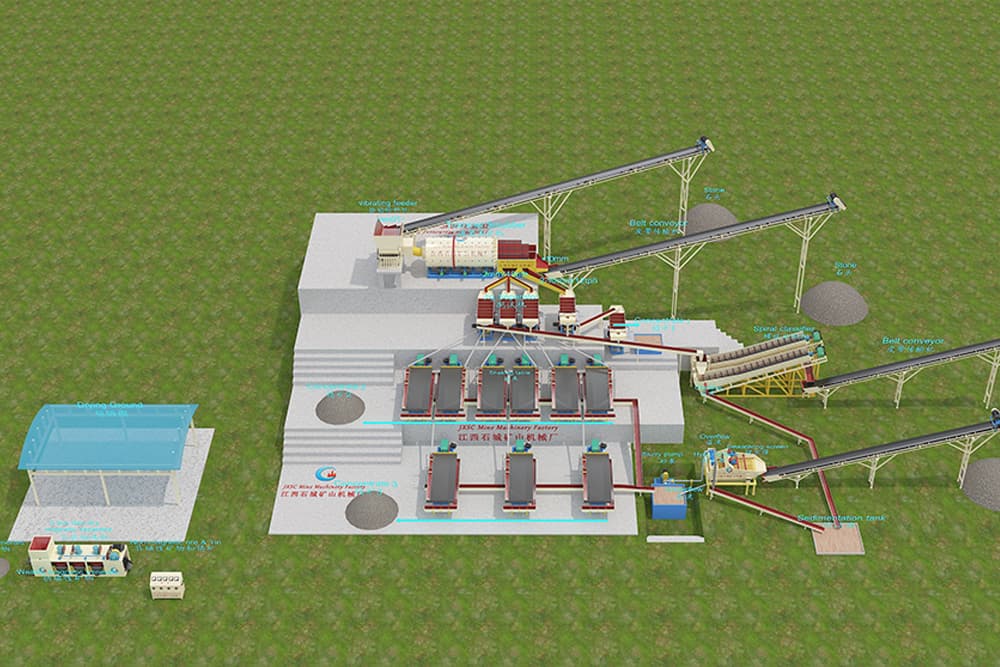

The process flow of tin ore recovery includes four parts: washing system, gravity separation system, magnetic separation and tailings dewatering system.

1. Washing system

The raw materials are evenly fed into the trommel scrubber by a vibrating feeder to wash away the clay and screen out the oversized waste rock. The vibrating feeder is equipped with a grid with a gap of 70mm, which can remove large waste rocks above 70mm. The trommel scrubber is equipped with two layers of 2mm and 10mm screens to screen out waste rocks above 0-2mm, 2-10mm, and 10mm.

The large waste rocks above 70mm from the vibrating feeder and the small waste rocks above 10mm from the trommel scrubber are sent to a distant place by a belt conveyor.

2. Gravity separation by jig separator and shaking table

The 0-2mm slurry from the drum ore washer is transported to the jig separator for primary selection of tin concentrate. The tin concentrate selected by the jig separator in the first stage is sent to the shaking table for further purification. In order to improve the recovery rate, the shaking table middlings are sent to the shaking table in the second stage for reprocessing to recover more tin concentrate.

The 2-10mm tin concentrate is transported from the trommel scrubber to another jig separator for primary concentration of tin concentrate. Its tin concentrate enters the second stage of the jig separator for fine selection to improve the tin grade.

3. Magnetic separation

The 0-2mm tin concentrate recovered by gravity separation is sent to a three-disc dry magnetic separator to further remove other impurities and improve the grade of the tin concentrate.

4. Tailings dewatering system

The tailings from the jig separator are sent to a spiral dewatering machine for dewatering, so that the tailings are dry and can be transported by a belt conveyor. The tailings water is recycled and reused.

All tailings from the shaking table are sent to the cyclone, the overflow of the cyclone is clear water, and the bottom flow enters the dewatering screen for further dehydration. The dry tailings on the screen and the muddy water under the screen enter the sedimentation tank.

The above is the beneficiation process of alluvial tin ore. Tin ore sample testing can also be carried out before production. JXSC has an ore testing laboratory and can provide all the equipment and technical support required for beneficiation. Welcome to consult and visit our factory.