Thickener

Capacity:1.3-1440 t/h

Applicable materials: gold cip & cil processing, ludge, wastewater, waste residue.

Description

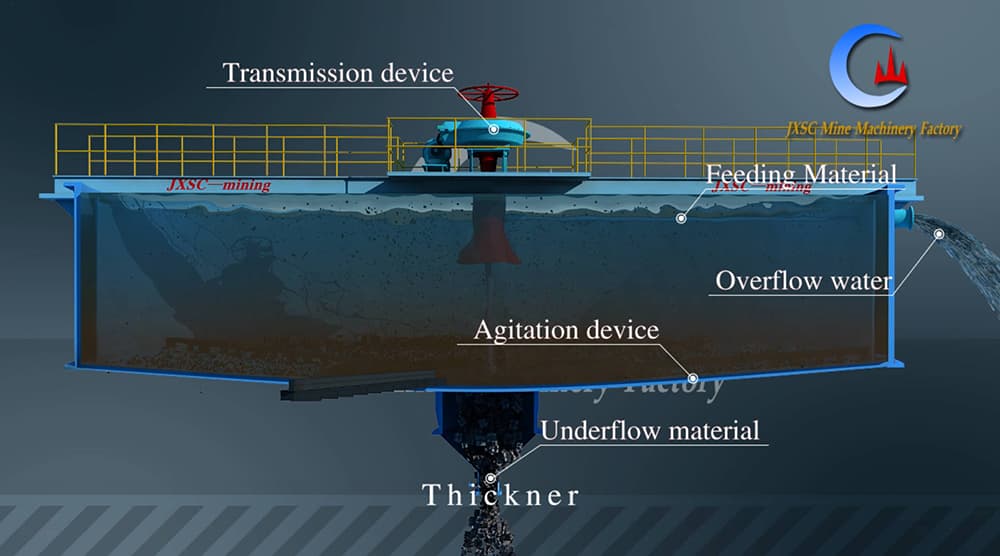

The thickener is a solid-liquid separation equipment based on gravity sedimentation. It is usually a cylindrical shallow tank with a cone bottom built from concrete, wood, or metal welded plates as structural materials. The slurry with a solid content of 10% to 20% can be concentrated through gravity sedimentation into an underflow slurry with a solid content of 45% to 55%. With the slow speed operation (1/3 to 1/5r/min) installed in the thickener can ), the thickened underflow slurry is discharged from the underflow port at the bottom of the thickener through the rake action. The thickener is generally mainly composed of a concentration tank, a cake frame, a transmission device, a cake frame lifting device, a feeding device, an unloading device, and a signal safety device. Its application fields are wide, including the processing of ore minerals, metallurgical alumina, chemical intermediate products, wastewater treatment in environmental protection projects, and the treatment of sludge and slag. The thickener can enrich the valuable elements in the ore through processes such as sedimentation, filtration, and concentration, thereby improving its grade and output.

Advantages

- Add flocculant to increase the particle size of settled solid particles, thereby speeding up the settling speed.

- Install inclined plates to shorten the settling distance of mineral particles and increase the settling area.

- Play the role of flocculation, filtration, compression, and increasing processing capacity of the dense phase layer of mud deposits.

- Equipped with complete automatic control facilities.

Principle

The working principle of the thickener is mainly to achieve the separation and enrichment of solid particles through processes such as sedimentation, filtration, and concentration. Specifically, the materials inside the thickener enter the middle plate or tank through the feed pipe and are then thoroughly stirred and mixed under the action of the stirring device. The solid particles gradually settle onto the filter media(such as filter cloth or screen) during the stirring process to form a filter cake. As the filter cake thickens, the pressure difference on the filter medium gradually increases, causing the water in the filter cake to be squeezed out, achieving solid-liquid separation. Finally, the materials inside the thickener are discharged from the tank, completing the entire thickening process.

Specification

| Center Drive Thickener Technical Parameters | |||||||

| Model | Thickener Tank | Sedimentation area (m2) | /Transmission speed(r/min) | Motor | /Capacity(t/d) | ||

| /Diameter (m) | Depth (m) | Model | /Power(kw) | ||||

| NZS1 | 1.8 | 1.8 | 2.55 | 0.5 | Y90L-6 | 1.1 | 1.3-5.6 |

| NZS2.5 | 2.5 | 1.8 | 4.9 | 0.33 | Y90L-6 | 1.1 | 5-10.8 |

| NZS3.6 | 3.6 | 1.8 | 10.2 | 0.38 | Y90L-6 | 1.1 | 5-22.4 |

| NZS6 | 6 | 2.956 | 28 | 0.35 | Y90L-4 | 1.5 | 14-60 |

| NZS8 | 8 | 3 | 50.2 | 0.27 | Y132S-6 | 3 | 25-120 |

| NZS9 | 9 | 3 | 63.5 | 0.25 | Y132S-6 | 3 | 32-150 |

| NZS12 | 12 | 3.6 | 113 | 0.19 | Y132S-6 | 3 | 50-250 |

| NZS15 | 15 | 3.6 | 176 | 0.1 | Y132M2-6 | 5.5 | 70-350 |

| NZS18 | 18 | 3.74 | 255 | 0.2 | Y160M-6 | 7.5 | 100-560 |

| NZS20 | 20 | 4.4 | 315 | 0.2 | Y160M2-8 | 7.5 | 200-1440 |

| NZS24 | 24 | 4.716 | 452 | 0.1 | Y180L-8 | 11 | 200-1440 |