Single Cylinder Cone Crusher

Widely used in metal and non-metallic ore, cement, sand, metallurgy and other industries, suitable for medium and fine crushing.

Capacity: 65-715 t/h

Applicable materials: various kinds of rocks and ores like cobble, granite, basalt, iron, limestone, quartzite, diabase, iron ore, gold ore,cooper ore, etc.

Description

The jaw crusher adopts the principle of mutual extrusion of jaw plates to process materials. It is used in the first process of crushing various ore rocks. It can process various ores with a compressive strength not higher than 320MPa to medium particle size at one time. It is often combined with cone crusher, impact crusher, sand making machine, etc. to form a complete sand and gravel production line。

PE type jaw crusher is suitable for coarse crushing and can crush ores within 750mm. PEX type jaw crusher is suitable for medium and fine crushing.

Main models: PE150×750, PE250×750, PE250×1000, PE250×1200, PE300×1300, etc.

Advantages

- Reasonable crushing cavity design, large production capacity, high crushing efficiency and low energy consumption.

- The iron passing design protects the normal operation of the equipment and improves the crushing efficiency. When encountering foreign objects that are difficult to crush, the hydraulic safety system lowers the main shaft and enlarges the discharge opening to discharge the foreign objects.

- The equipment has excellent sealing performance, simple structure, strong reliability, easy maintenance and low operating cost.

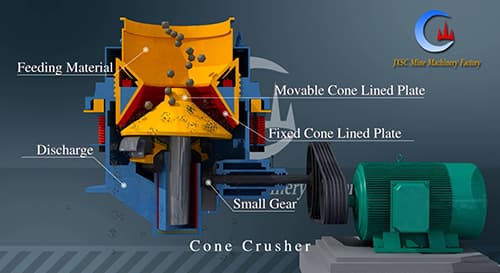

Principle

DNGP Series Single Cylinder Cone Crusher has an adjustable outlet. The machine is equipped with an operation panel, which is convenient for users to use. The machine parameters can be accurately set and the size of the discharge port can be adjusted through the operation panel. When working, the hydraulic oil pump will inject or drain oil into the spindle cylinder to adjust the height of the spindle, thereby changing the distance between the rolling wall and the crushing wall, thereby adjusting the size of the discharge port.

Specification

| MODEL | CHAMBER | FEED OPENING MM | MAX FEEDING SIZE MM | MINIMUM DISCHARGE MM | MAXIMUM DISCHARGE MM | MOTOR POWER | MACHINE WEIGHT | CAPACITY t/h | ||||

| STROKE | STROKE | STROKE | STROKE | STROKE | STROKE | KW | KG | |||||

| DNGP100 | A | 150 | 120 | 12 | 15 | 30 | 39 | 37 | 40 | 90 | 5800 | 35-135 |

| B | 130 | 105 | 10 | 11 | 26 | 33 | 31 | 38 | ||||

| C | 100 | 85 | 7 | 9 | 16 | 33 | 30 | 30 | ||||

| DNGP200 | A | 220 | 180 | 18 | 22 | 30 | 35 | 30 | 30 | 160-220 | 12300 | 85-350 |

| B | 150 | 120 | 15 | 19 | 26 | 35 | 30 | 30 | ||||

| C | 80 | 60 | 9 | 12 | 35 | 30 | ||||||

| DNGP300 | A | 230 | 190 | 20 | 25 | 45 | 40 | 250-280 | 16500 | 115-400 | ||

| B | 150 | 125 | 17 | 20 | 45 | 40 | ||||||

| C | 80 | 60 | 10 | 13 | 40 | 35 | ||||||

| DNGP500 | A | 230 | 180 | 22 | 26 | 50 | 45 | 315 | 25800 | 245-500 | ||

| B | 150 | 125 | 19 | 22 | 48 | 43 | ||||||

| C | 100 | 80 | 12 | 14 | 40 | 35 | ||||||

| DNGP600 | A | 280 | 220 | 22 | 26 | 45 | 35 | 355 | 26700 | 280-715 | ||

| B | 150 | 125 | 19 | 22 | 45 | 35 | ||||||