Flotation Separator

Capacity: 0.2-20 t/h

Applicable materials: separate gold, antimony ore, lithium, copper, zinc, lead, nickel, molybdenum ore, graphite ore, fluorite ore, feldspar, tungsten ore, etc.

Description

Flotation machines mainly separate valuable ores from gangue minerals through chemical and physical interactions. It is very effective in processing non-ferrous metal ores, such as copper, lead, zinc, nickel, etc.; it can also be used for rough selection and selection of ferrous metals and non-metals. JXSC provides various types of flotation equipment, including mechanical agitation, aerated agitation, and rod flotation machines. It can effectively remove impurities and pollutants in the slurry, achieve clean separation and recover high-grade concentrate.

Advantages

- The stirring force is strong, the trajectory circulation of slurry and air is reasonable, and the sorting accuracy is high;

- JXSC flotation machine can process a wide range of particle sizes and has strong adaptability;

- Equipped with an advanced adjustment system to realize automatic control;

- Low power consumption, low operating costs, low wear, and long service life.

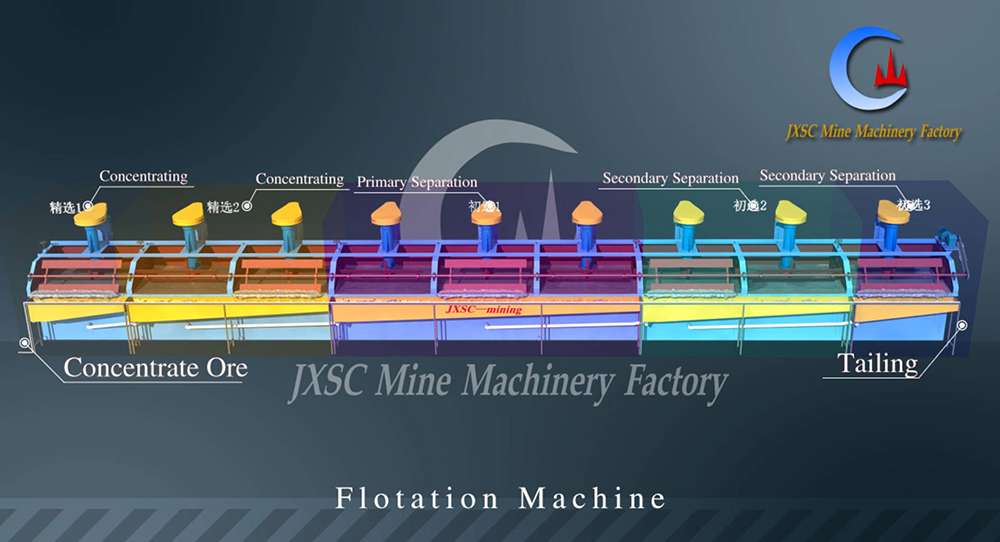

Principle

Put the ground ore into the mixing tank, add water or necessary chemicals to form a slurry, and then inject it into the flotation machine. Air is introduced into the slurry to form a large number of bubbles. Some mineral particles not easily wetted by water, generally called hydrophobic, are attached to the bubbles. Then, it floats to the surface of the slurry and is scraped out to form a foam product; the rest is retained in the slurry, and the mineralized bubbles containing specific minerals are discharged to separate minerals.

Specification

| Model | Volume m³ | Cell size mm | Impeller Dia.mm | Impeller speed r/min | Capacity m³/min | Power kw | Singe cell weight kg |

| SF-0.37 | 0.37 | 700x700x750 | 296 | 386 | 0.2-0.4 | 1.5/0.55 | 468 |

| SF-0.7 | 0.7 | 820x900x950 | 350 | 400 | 0.3-0.9 | 3/1.1 | 805 |

| SF-1.2 | 1.2 | 1100x1100x1100 | 450 | 312 | 0.6-1.2 | 5.5/1.1 | 1373 |

| SF-2.8 | 2.8 | 1700x1600x1150 | 550 | 268 | 1.5-3.5 | 11/1.5 | 2138 |

| SF-4 | 4 | 1850x2050x1200 | 650 | 220 | 2–4 | 15/1.5 | 2582 |

| SF-8 | 8 | 2200x2900x1400 | 760 | 191 | 4–8 | 30/1.5 | 4129 |

| SF-10 | 10 | 2200x2900x1700 | 760 | 191 | 5–10 | 30/1.5 | 4486 |

| SF-16 | 16 | 2850x3800x1700 | 760 | 191 | 5–16 | 30×2/1.5 | 8320 |

| SF-20 | 20 | 2850x3800x2000 | 760 | 191 | 5–20 | 30×2/1.5 | 9829 |

| There are also GF type self-priming flotation machine, XCF type aerated mechanical agitation flotation machine, KYF type aerated mechanical agitation flotation machine specifications and dimensions please contact us. | |||||||