Gold Centrifugal Concentrator

Gold centrifugal concentrator is widely used to recover useful minerals from fine mud. It is mainly used for the enrichment of placer gold, vein gold and other non-ferrous metal associated gold.

Capacity: 0.5-60 t/h

Applicable materials: precious metals, including gold ore, silver ore, chromite, platinum group, tungsten ore, tin ore, iron ore and other metals

Capacity: 0.5-60 t/h

Applicable materials: precious metals, including gold ore, silver ore, chromite, platinum group, tungsten ore, tin ore, iron ore and other metals

Description

The gold centrifugal concentrator is gravity separation equipment, mainly used for primary concentration of gold and other precious metals,such as free gold in alluvial gold, grinded rock gold, gold tailings, platinum group precious metals, etc.

Gold centrifugal concentrator has two types: intermittent ore discharge and continuous ore discharge. Intermittent ore discharge is suitable for low-grade raw ore, and continuous ore discharge is suitable for higher-grade raw ore.

Gold centrifugal concentrator has two types: intermittent ore discharge and continuous ore discharge. Intermittent ore discharge is suitable for low-grade raw ore, and continuous ore discharge is suitable for higher-grade raw ore.

Advantages

- It has good processing effect on fine sludge, and the enrichment rate is higher than other gravity mineral processing equipment.

- The stratification and ore discharge speed is fast, and the sorting efficiency is high.

- The work does not require the use of chemical reagents and protects the environment.

- You can choose the gold centrifugal concentrator for automatic ore discharge, which is easy to operate and automatically collects ore.

Principle

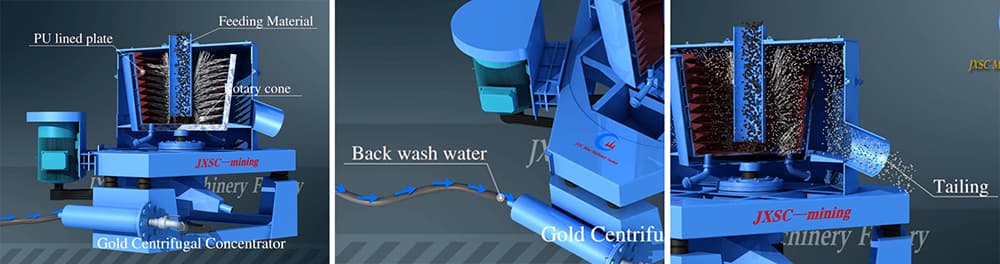

The slurry is fed in from the ore feed port. The drum in the Gold centrifugal concentrator rotates at high speed, and the slurry moves with it. Under the action of centrifugal force, the heavy minerals in the slurry precipitate on the inner wall of the drum, and the light ore particles rotate with the drum to the end. discharge.

Specification

| Model | Capacity (t/hr) | Feeding Size (mm) | Feeding Density (%) | Power (kw) | Cone Rotate Speed (RPM) | Back Water Required (m3/h) | Dimension (mm) |

| STLB20 | 0.5-1 | 0-2.5 | 20-50 | 1.1 | 800 | 15 | 800*560*710 |

| STLB30 | 2-3 | 0-4 | 20-50 | 2.2 | 600 | 20 | 1280*1030*1135 |

| STLB60 | 8-12 | 0-6 | 20-50 | 7.5 | 460 | 50 | 1850*1550*1600 |

| STLB80 | 10-20 | 0-6 | 20-50 | 15 | 400 | 80 | 2300*1800*2200 |

| STLB100 | 40-60 | 0-6 | 20-50 | 18 | 360 | 100 | 2400*2400*2250 |