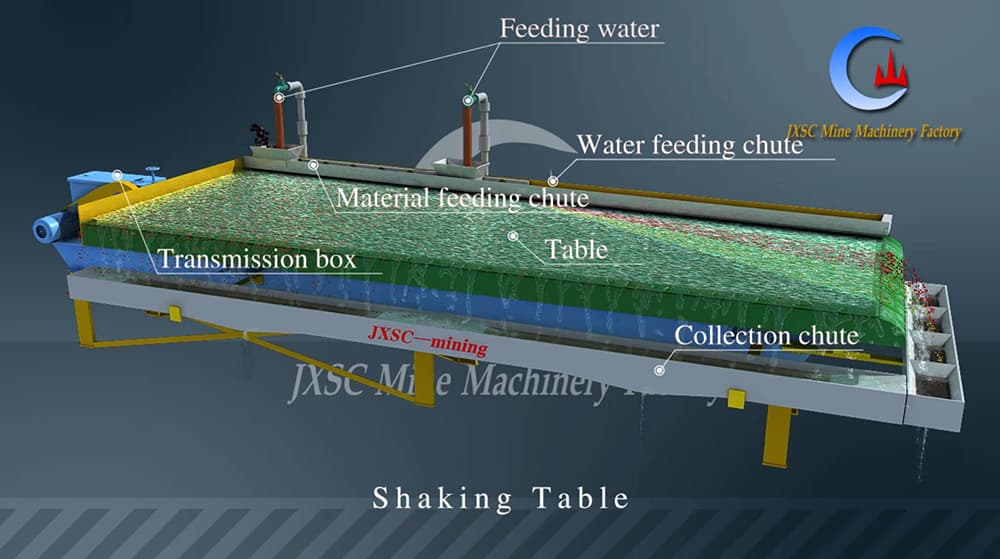

Shaking Table

Shaking table is one of the main equipments of gravity beneficiation equipment, which is suitable for separation of light and heavy minerals with obvious difference in specific gravity。

Capacity: 0.05-2 t/h

Applicable materials: gold ore, tin ore, chromium ore, tantalum and niobium ore, tungsten ore, iron ore, manganese ore, chromium ore Ore, silica sand, beach sand, zircon sand, monazite, etc., the best sorting size is 0-2mm.

Description

Shaking table is commonly used in the concentrator process of mineral processing. It can be used for roughing, selecting and other different operations, sorting coarse sand (2-0.5mm), fine sand (0.5-0.074mm), slime (-0.074), and other different granularity minerals. (Learn more about gold shaker tables)

Advantages

- The countertop made of emery, epoxy resin and fiberglass fabric is more wear-resistant, and stronger, has good sorting effect, and long service life.

- Thickened steel frame, better quality. It is 50cm higher than the ordinary shaker, making it more convenient to work.

- The feeding trough and collecting trough are made of PP material, which is more wear-resistant.

- Belt pulley with protective cover, safer operation.

Principle

The motor drives the belt pulley and the shaking table starts working. The slurry is sent to the feeding trough, mixed with water to form a slurry of a certain concentration, and flows to the bed surface. Under the combined action of the longitudinal reciprocating motion of the shaking table bed surface and the transverse water flow, the minerals are partitioned on the bed surface according to different specific gravity. The light mineral particles are pushed further by the water flow and move farther in the lateral direction, flowing to the tailings side; the heavy mineral particles are driven by the longitudinal reciprocating motion of the bed surface and flow to the concentrate end, thereby completing the separation work.

Specification

| Deck type | Unit | Course sand | Fine sand | Slime Deck | Three different kinds of decks are available | |||

| Beneficiation Area | m2 | 7.6 | 7.6 | 7.6 | 4.08 | 1.95 | 0.5 | |

| Deck Size | Length | mm | 4450 | 4450 | 4450 | 3000 | 2100 | 1100 |

| Transmission end width | mm | 1855 | 1855 | 1855 | 1320 | 1050 | 500 | |

| concentrate end width | mm | 1546 | 1546 | 1546 | 1100 | 850 | 430 | |

| Maximum Feeding Size | mm | 2 | 0.5 | 0.15 | 0.1-2 | 0.074-2 | 0.074-2 | |

| Process Capacity | t/h | 1.5-2 | 0.8-1.5 | 0.5-0.8 | 0.4-1.5 | 0.3-0.8t | 0.05-0.2 | |

| Feeding Density | % | 25-30 | 20-25 | 15-25 | 10-30 | |||

| Stroke | mm | 16-22 | 11-16 | 8-16 | 6-30 | 12-28 | 9-17 | |

| Frequency | f | 45-48 | 18-53 | 50-57 | 210-320 | 250-450 | 280-460 | |

| Water added | t/d | 80-150 | 30-60 | 10-17 | 0.3-1.5t/h | 0.2-1t/h | 0.1-0.5t/h | |

| Transverse slope of Deck | ° | 2° 30-4° 30 | 1° 30-3° 30 | 1° -2° | 0 -10° | 0 -8° | 0 -10° | |

| Longitudinal slope of Deck | ° | 1.4 | 0.92 | —— | —— | —— | —— | |

| Cross-section Shape of Deck | rectangular | saw tooth | triangle | Avaliable rectangular, saw tooth, triangle | ||||

| Motor Power | KW | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | |