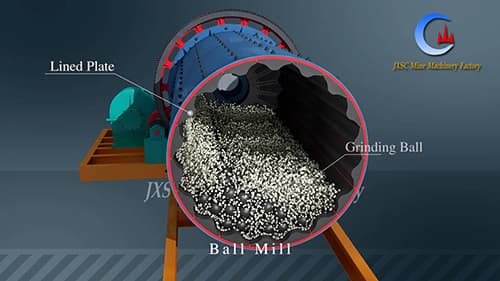

Ball Mill

It is also widely used in cement, silicate products, and new building materials. refractory material. Fertilizer, black and non-ferrous metal beneficiation and glass ceramics and other production industries.

Capacity: 0.4-150 t/h

Applicable materials: Gold ore, cooper ore, magnetite ore, antimony, calcite, kaolin, mica, clay, bentonite, chrome and other ores for grinding.

Description

The ball mill is the key equipment for crushing after the material is crushed.

It can be used for dry or wet grinding of various ores and other grindable materials.

The ball mill is composed of feeding part, discharging part, rotary part, transmission part (reducer, small transmission gear, motor, electric control) and other main parts.

The hollow shaft is made of cast steel. The inner lining is removable, and the rotary gear is processed by casting hobbing. There is a wear-resistant liner in the simplified body, which has good wear resistance.

Grinding methods:

Dry grinding: suitable for materials that react easily with water, areas with limited water resources, or when the fineness requirement of the final product is not high.

Wet grinding: suitable for most materials, including copper ore, iron ore, molybdenum ore, phosphate ore, feldspar ore, fluorite ore, etc.

Types of ball mills:

Grate type ball mill: equipped with a grating at the front end of the discharge, which forces the discharge and effectively avoids over-grinding.

Overflow type ball mill: suitable for secondary grinding or when there is a higher requirement for the fineness of the final product.

Grinding media: Mainly include steel balls, alumina balls, zirconia balls, etc.

Advantages

- Double-row spherical roller bearings make it easier to start and more energy-efficient.

- The wave-shaped liner increases the contact area between the balls and the ore, improving efficiency and reducing energy consumption.

- There are multiple choices for liner materials, and high wear-resistant rubber liners have excellent wear resistance and long service life.

- The large discharge opening allows for high production capacity.

Principle

In a ball mill, 30-40% of steel balls are placed depending on the model. After the ball mill starts operating, the cylinder rotates. Stones enter the interior of the ball mill through the feed inlet. With the rotation of the ball mill, the stones and steel balls collide and rub against each other, eventually grinding the stone ore into fine powder.

Specification

| Model | Drum size(m) | Rotation speed (r/min) | Ball load(t) | Feeding size(mm) | Output size(mm) | Capacity(t/h) | Motor power(kw) | Weight(t) |

| MQZ0918 | 0.9*1.8 | 38.8 | 1.92 | < =20 | 0.074-0.6 | 0.4-2.14 | 22 | 5.34 |

| MQZ0930 | 0.9*3.0 | 36 | 2.7 | < =20 | 0.074-0.6 | 1.1-3.5 | 22 | 6.98 |

| MQZ1224 | 1.2*2.4 | 31 | 4.8 | < =20 | 0.074-0.6 | 0.4-6.8 | 37 | 13.43 |

| MQZ 1245 | 1.2*4.5 | 31 | 5.2 | < =20 | 0.074-0.4 | 1.6-12 | 75 | 17.4 |

| MQZ 1530 | 1.5*3.0 | 27.5 | 8.1 | < =25 | 0.074-0.4 | 2.9-16.5 | 80 | 18.6 |

| MQZ 1557 | 1.5*5.7 | 29.2 | 15 | < =25 | 0.074-0.4 | 4.1-25 | 130 | 24.54 |

| MQZ 1836 | 1.8*3.6 | 23.9 | 11 | < =25 | 0.074-0.4 | 8-40 | 155 | 33 |

| MQZ2136 | 3.1*3.6 | 23.8 | 27 | < =25 | 0.074-0.4 | 8-61 | 210 | 46.8 |

| MQZ2436 | 2.4*3.6 | 22 | 28 | < =25 | 0.074-0.4 | 7-95 | 240 | 73 |

| MQZ2465 | 2.4*6.5 | 22 | 36 | < =25 | 0.074-0.4 | 7-110 | 310 | 76 |

| MQZ2736 | 2.7*3.6 | 21.9 | 39 | < =25 | 0.074-0.4 | 13-145 | 400 | 77 |

| MQZ2740 | 2.7*4.0 | 21.9 | 43 | < =25 | 0.074-0.4 | 13-150 | 400 | 91 |

| MQZ3060 | 3.0*6.0 | 19 | 70 | < =25 | 0.074-0.4 | 100-150 | 800 | 155 |