Wet Drum Magnetic Separator

Capacity: 0.1-180 t/h

Applicable materials: Iron removal operations for iron ore, magnetite, ilmenite, tantalum-niobium ore, siderite, limonite, tungsten ore and other materials.

Description

Wet drum magnetic separator is a magnetic separation equipment commonly used in iron ore beneficiation plants. Efficiently and effectively separates magnetic and non-magnetic materials from slurry streams. In the mining industry, wet drum magnetic separators are used to ensure high purity and quality of the final product by removing iron impurities. JXSC wet drum magnetic separator is equipped with powerful functions such as variable speed control and automatic unloading mechanism. The magnetic roller coefficient can be customized to make it more adaptable to different processing requirements.

Advantages

- The wet drum magnetic separator can continuously feed and discharge ore, and has high processing capacity;

- It has high magnetic recovery efficiency and can extract valuable magnetic materials to the maximum extent;

- Its durable construction ensures reliability under harsh operating conditions;

- High sorting accuracy is beneficial to improving the grade of ore.

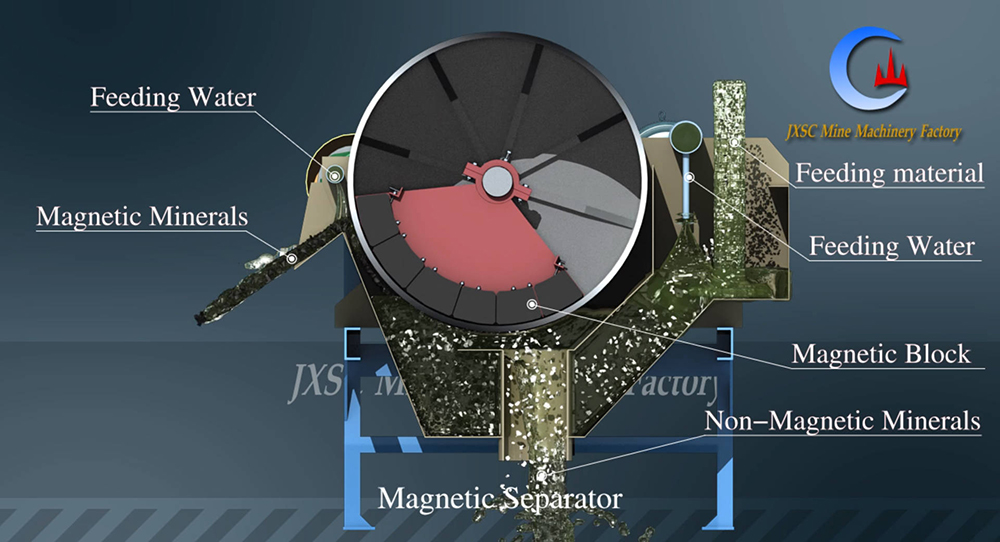

Principle

When the slurry enters the magnetic field area of wet drum magnetic separator, the strongly magnetic minerals are adsorbed on the surface of the cylinder, and the weakly magnetic and non-magnetic minerals are thrown off and discharged. The strong magnetic minerals adsorbed on the surface of the cylinder are taken out of the magnetic field area as the cylinder rotates and washed with water into the concentrate tank to complete the sorting operation.

Specification

| Model | Shell diameter (mm) | Shell length (mm) | Shell rotation speed (r/min) | Feeding size (mm) | Processing capacity (t/h) | Power (kw) |

| CTB4060 | 400 | 600 | 48 | 2-0 | 0.5-1 | 1.1 |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10–20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15–30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20–45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40–60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45–60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45–70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50–75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50–100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60–120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80–140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85–180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100–180 | 7.5 |