Rotary Vibration Screen

Widely used in food, ceramic, chemical, pharmaceutical industry, metallurgy, pollution abatement, etc.,

Applicable materials:Iron powder, aluminum powder, lead powder, copper powder, alloy powder, electrolytic copper powder, refractory materials, steel shot, alumina, metal metallurgical powder, etc.,

Description

The rotary vibrating screen is designed as a high-precision screening machinery. It’s mainly used for grading, removing impurities, and solid-liquid separation to improve product quality. With the external output and stackable design, this ingenious and simple machine can continuously filter up to 5 stages of product separation in just 1 operation.

The sieving screen with a tightly controlled aperture size is essential to achieving a reliable, efficient screening outcome. Our sieve screen is made of stainless steel woven wire cloth, with a mesh count of 3–508 mesh to satisfy different needs for powder sieving. Our rotary vibrating screens are available in various sizes, suitable for smaller and larger scale operations from Ø400 to Ø2000, and with single or multiple screening decks.

Advantages

- Fine filter: In the rotary vibrating screen, the sieve cloth is a stainless steel wire woven mesh, and the smallest can reach 600 mesh (0.02mm). The counterweight rapid adjustment system can control and adjust the material movement on the sieve cloth, and maintain a long screening time to complete the fine screen.

- High throughput: Horizontal, inclined, vertical 3D vibratory motion for higher vibrations, 3 times higher throughput through precise screening, it allows throughputs from 100 to 5,000 kg/h depending on the product, mesh size, and machine feed flow.

- No dust pollution: The rotary vibrating screen can be used with a hose to achieve full sealing without dust, floating powder, and liquid splashing. It is very suitable for sanitary production lines and dust-free workshops, and it is also very helpful to protect the health of your employees.

- Good adaptability: The height of the machine can be specially customized according to customer requirements. The discharge port can be placed 360 degrees, which is convenient for other equipment in the production line.

Principle

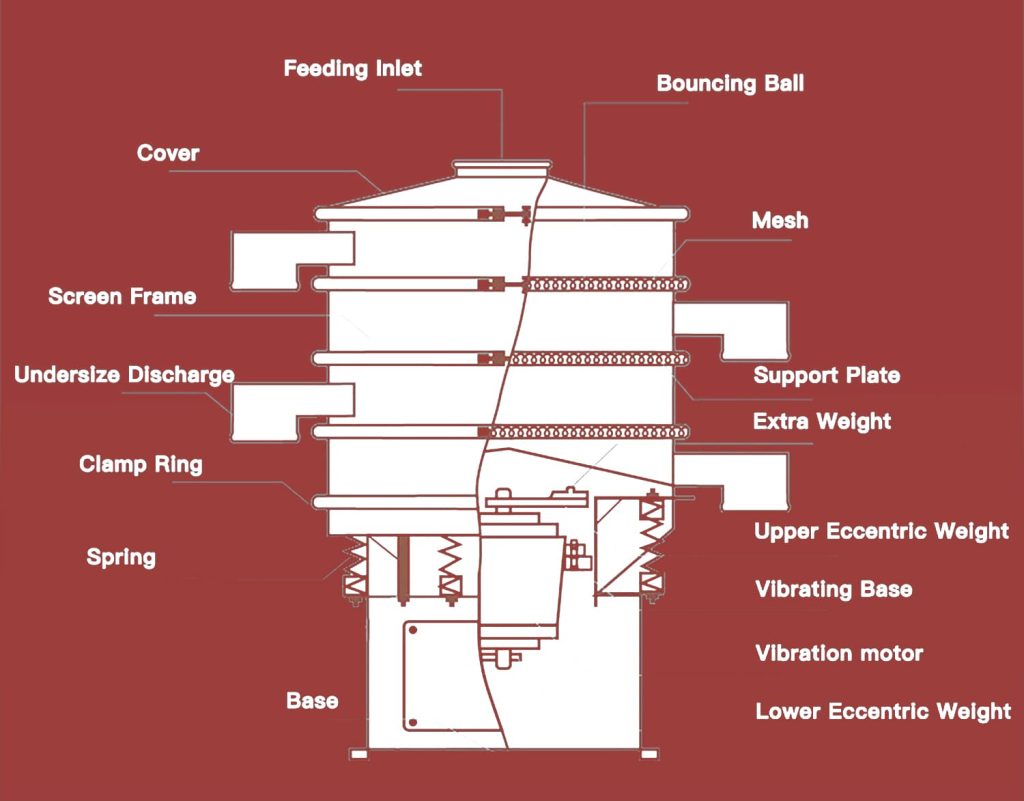

The rotary vibrating screen uses a vertical vibration motor as the exciter. The upper and lower ends of the vibration motor are equipped with eccentric weights, which convert the rotational motion of the vibration motor into horizontal, vertical, and tilted three-dimensional motion and then transfer this motion to the Screen surface. Adjusting the phase angles of the upper and lower ends can change the movement trajectory of the material on the screen surface.

Specification

| Model | Screening Size (m²) | Layer | Screen Diameter(mm) | Screen Mesh(mesh) | Motor Power (kw) | |

| 600 | 0.2281 | 1-5 | Φ540 | 2-500 | 0.55 | 0.75 |

| 800 | 0.4183 | 1-5 | Φ730 | 2-500 | 0.75 | 1.1 |

| 1000 | 0.6359 | 1-5 | Φ900 | 2-500 | 1.1 | 1.5 |

| 1200 | 0.9499 | 1-5 | Φ1100 | 2-500 | 1.5 | 1.5 |

| 1500 | 1.5386 | 1-5 | Φ1400 | 2-500 | 2.2 | 2.2 |

| 1800 | 2.2687 | 1-3 | Φ1700 | 2-500 | 3.0 | 2.2 |

| 2000 | 2.7922 | 1-3 | Φ1886 | 2-500 | 3.7 | 3.0 |