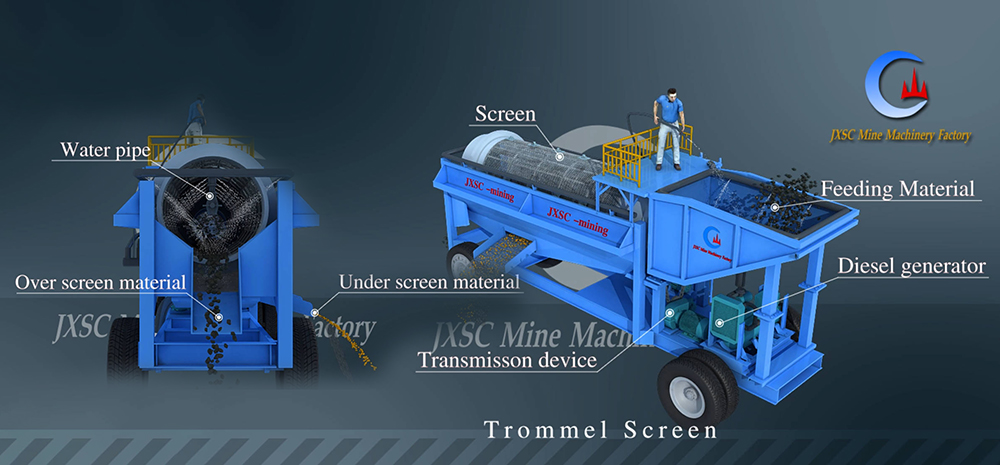

Trommel Screen

Capacity: 1-200 t/h

Applicable materials: Screening and washing of gold ore, barite, quartz stone, silica sand, kaolin, chromium ore, iron ore, tantalum-niobium tin ore, cobblestone, garnet, mountain sand, soil, compost, etc., rocks, aggregates, sand or minerals.

Description

Trommel screen, also known as a rotary screen, is an innovative and efficient equipment for screening and grading a wide range of materials. It can screen various types of materials, such as rock, aggregate, rock, gravel, minerals, soil or sand. It is commonly used in various mining operations such as gold mining, mineral extraction, and aggregate processing. It can also be equipped with a water-flushing pipe to clean the soil or impurities on the material’s surface while screening. JXSC supports customized mobile or modular trommel screens, which are flexible and can be assembled according to specific processing requirements.

Advantages

- The trommel screen has a self-cleaning function, the screen holes are not easily clogged, and the service life is long;

- The circular screen body has a large effective area for screening, so the screening capacity per unit time is large;

- The entire screening mechanism is designed in a sealed dust cover, with almost no dust and noise pollution;

- Customizable screen mesh size to meet screening requirements for different materials.

Principle

The trommel screen is usually made of mesh or perforated metal and mainly rotates around a cylindrical drum to separate materials of different sizes. When the material enters the internal screen, due to the tilt and rotation of the drum device, the material on the screen surface is flipped and rolled, so that the qualified materials (products under the screen) are discharged through the screen on the outer circumference of the drum. Unqualified materials (products on the screen) are discharged through the end of the drum. Due to the flipping and rolling of materials in the drum, materials stuck in the screen holes can be ejected to prevent the screen holes from being blocked.

Specification

| Model | Screen Size (mm) | Feeding Size (mm) | Drum Dia (mm) | Drum length (mm) | Process Capacity (t/h) | Motor Power(kw) |

| GT0513 | ≤20 | ≤80 | 500 | 1300 | 1-5 | 3 |

| GT0813 | ≤20 | ≤80 | 800 | 1300 | 5-10 | 4 |

| GT1015 | ≤20 | ≤80 | 1000 | 1500 | 10-15 | 5 |

| GT1020 | ≤25 | ≤80 | 1000 | 2000 | 15-20 | 5.5 |

| GT1225 | ≤25 | ≤100 | 1200 | 2500 | 20-50 | 7.5 |

| GT1530 | ≤25 | ≤100 | 1500 | 3000 | 40-70 | 11 |

| GT1545 | ≤25 | ≤100 | 1500 | 4500 | 70-100 | 15 |

| GT1848 | ≤50 | ≤100 | 1800 | 4800 | 100-150 | 22 |

| GT2055 | ≤50 | ≤100 | 2000 | 5500 | 150-200 | 30 |