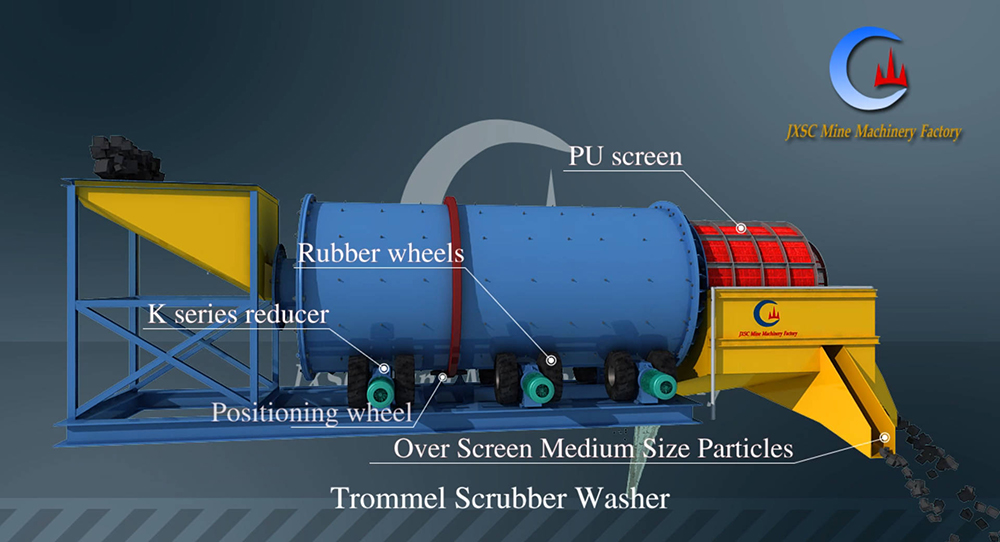

Trommel Scrubber

Capacity: 1-400 t/h

Applicable materials: placer gold ore, diamond ore, iron ore, silica ore, copper ore, manganese ore, tantalum-niobium ore, placer tin ore, phosphate ore, bauxite, barite, fluorite, garnet, Diamond, cement, quartz sand, steel sand, slag powder, etc.

Description

Trommel scrubber is used for cleaning sand mines with large mud content and high viscosity. It is often used to remove slime from minerals before crushing and beneficiation to facilitate subsequent operations. The inner wall of the trommel scrubber cylinder is equipped with a wear-resistant lining plate to prevent stone impact damage to the cylinder. It can be connected with a single-layer or multi-layer trommel screen to complete the washing and screening at the same time. The trommel scrubber can handle ores with large particle sizes and has good cleaning effect. It is an indispensable washing machine in the processing of large ores.

The drum trommel scrubber is very suitable for ores such as bauxite, silica ore, barite ore, manganese ore, limonite, etc. whose raw ores contain a large amount of sticky mud.

Advantages

- Ore washing and screening are completed at the same time, and large-grained ores can be processed.

- It has wide applicability, large processing capacity and strong cleaning ability for mud-containing minerals.

- The screen can be customized and used in multiple layers to obtain finished products of various specifications.

Principle

The gear transmission device drives the cleaning cylinder to rotate. Materials with mud are fed into the drum from the feed port. There are washing blades in the drum. The drum rotates and drives the materials to be continuously thrown up and down. In the process, it collides with the washing blades and is washed by high-pressure water flow. The minerals and mud are gradually dispersed. . During the cleaning process, the minerals gradually move to the discharge end, pass through the sieve, and are classified into minerals of various particle sizes before being discharged.

Specification

| Model | Drum Dia(mm) | Drum&Screen Length (M) | Screen Mesh Size(mm) | Rotation Speed (r/min) | Feeding Size(mm) | Angle of Inclination(o) | Process Capacity(t/h) | Motor Power(kw) |

| JXSC-400 | 400 | 2m+1.2m | ≤20 | 27.9 | ≤80 | ≤10 | 1-5 | 3 |

| JXSC-600 | 600 | 2m+1.2m | ≤25 | 27.6 | ≤80 | ≤10 | 5-10 | 4 |

| JXSC-750 | 750 | 2.5m+1.5m | ≤25 | 27.6 | ≤100 | ≤10 | 10-20 | 5 |

| JXSC-900 | 900 | 3m+1.8m | ≤25 | 27.6 | ≤100 | ≤10 | 20-40 | 11 |

| JXSC-1200 | 1200 | 4m+2m | ≤25 | 17 | ≤100 | ≤10 | 40-70 | 15 |

| JXSC-1500 | 1500 | 4m+2m | ≤50 | 16 | ≤100 | ≤10 | 70-100 | 30 |

| JXSC-1800 | 1800 | 4m+2m | ≤50 | 16 | ≤100 | ≤10 | 100-150 | 18.5*2 |

| JXSC-2100 | 2100 | 4m+2m | ≤50 | 16 | ≤100 | ≤10 | 150-200 | 22*2 |

| JXSC-2400 | 2400 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 200-250 | 22*4 |

| JXSC-2700 | 2700 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 250-270 | 55*2 |

| JXSC-3000 | 3000 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 270-300 | 30*4 |

| JXSC-3200 | 3200 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 300-340 | 37*4 |

| JXSC-3400 | 3400 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 340-370 | 45*4 |

| JXSC-3600 | 3600 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 370-400 | 55*4 |