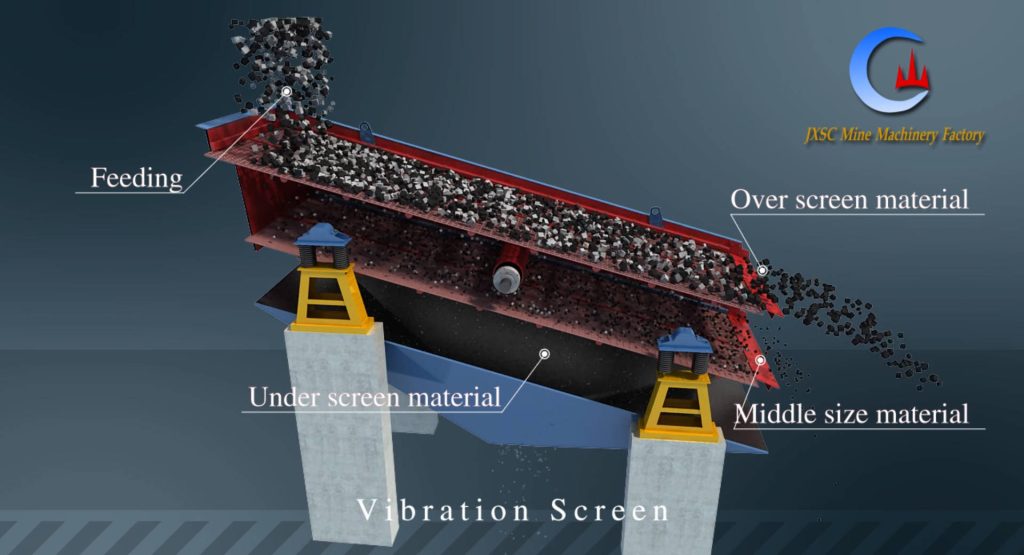

Vibrating Screen

Mainly used in mining, coal, smelting, building materials, refractory materials, light industry, chemical industry, medicine, food and other industries.

Applicable materials:Vibrating screens are used for coarse, medium, and ultra-fine screening of materials of ores, such as quartz, iron, granite, coal, pebbles, limestone, granite, basalt, diabase, ferrous metals ore (e.g. iron, tin, tungsten, tantalum, etc.) and nonferrous metals ores (e.g. lead, zinc, gold, silver, and industrial sand, etc.)

Description

A vibrating screen is a commonly used screening equipment and is widely used in many industries. Vibrating screens can be divided into different types according to screening requirements and working environments.

Classification of vibrating screens

According to the weight and use, we can divide the vibrating screening equipment into mining vibrating screens, light fine vibrating screens, and experimental vibrating screen machines.

- Mining vibrating screens: High-efficiency & heavy-duty vibrating screens, self-centering vibrating screens, elliptical vibrating screens, dewatering screens, circular vibrating screens, linear vibrating screens, etc.

- Light fine vibrating screens: Rotary vibrating screens, linear vibrating screens, straight row screens, ultrasonic vibrating screens, filter screens, etc.

- Experimental vibrating screen: slap screen, top impact vibrating screen machine, standard inspection screen, electric vibrating screen machine, etc.

According to the material running trajectory of the vibrating screen, it can be divided into the linear vibrating screen (materials move forward in a straight line on the screen surface) and the circular vibrating screen (materials move in a circular motion on the screen surface).

Vibrating screens are most commonly used in mineral processing plants. According to their different transmission mechanisms, we can divide them into the following types: eccentric vibrating screens, inertial vibrating screens, self-centering vibrating screens, and resonant vibrating screens.

Vibrating screens are mainly used in mining, metallurgy, building materials, roads, railways, water conservancy, and chemical industries. Screening and classifying medium-sized materials like sand, ore granular, and cement are very important before further processing these materials. Also, a vibrating screen is applied in de-water, de-slime, and heavy medium operation.

Advantages

- Due to the strong vibration of the screen box, the phenomenon of materials blocking the screen holes is reduced, making the screen have higher screening efficiency and productivity.

- The structure is simple, and the screen surface is easy to replace.

- Screening consumes less electricity per ton of material.

Principle

reen surface. In contrast, transverse vibration makes the material move along the horizontal direction of the screen surface. The vibration forces in these two directions act alternately, causing the material to sway back and forth on the screen to separate materials of different particle sizes.

Specification

| Model | Screening Size (m²) | Vibration Amplitude (mm) | Motor Model | Motor Power | Rotating speed(r.p.m) |

| DZS0410 | 0.4*1.0 | 2-4 | YZO-3-6 | 0.25 | 960 |

| DZS0412 | 0.4*1.2 | 2-4 | YZO-3-6 | 0.25 | 960 |

| DZS0415 | 0.4*1.5 | 2-4 | YZO-3-6 | 0.25 | 960 |

| DZS0612 | 0.6*1.2 | 3-5 | YZO-3-6 | 0.25 | 960 |

| DZS0718 | 0.7*1.8 | 3-5 | YZO-10-6 | 1 | 960 |

| DZS0815 | 0.8*1.5 | 4-6 | YZO-18-6 | 1.1 | 960 |

| DZS0918 | 0.9*1.8 | 4-6 | YZO-20-6 | 2 | 960 |

| DZS0922 | 0.9*2.2 | 4-6 | YZO-20-6 | 2*1.5 | 960 |

| DZS1018 | 1.0*1.8 | 4-6 | YZO-16-6 | 2*1.1 | 960 |

| DZS1020 | 1.0*2.0 | 4-6 | YZO-16-6 | 2*1.1 | 960 |

| DZS1225 | 1.25*1.25 | 4-6 | YZO-20-6 | 2*2 | 960 |

| DZS1530 | 1.5*3.0 | 4-6 | YZO-36-6 | 2*3 | 960 |

| DZS21530 | 1.5*3.0 | 4-6 | YZO-36-6 | 2*3 | 960 |

| DZS1536 | 1.5*3.6 | 4-6 | YZO-36-6 | 2*3 | 960 |