Alluvial Gold Processing Plant

Alluvial(Sand) gold refers to a sandy substance containing a certain proportion of gold. When the gold ore rocks weather to the point of cracking, the gold breaks away from the veins and settles along with the sediment at the bottom of the river, forming alluvial (placer/sand) gold. The beneficiation process of placer gold ore mainly includes gravity separation and flotation. The processes are crushing, washing and screening, roughing and concentrating.

Process Description

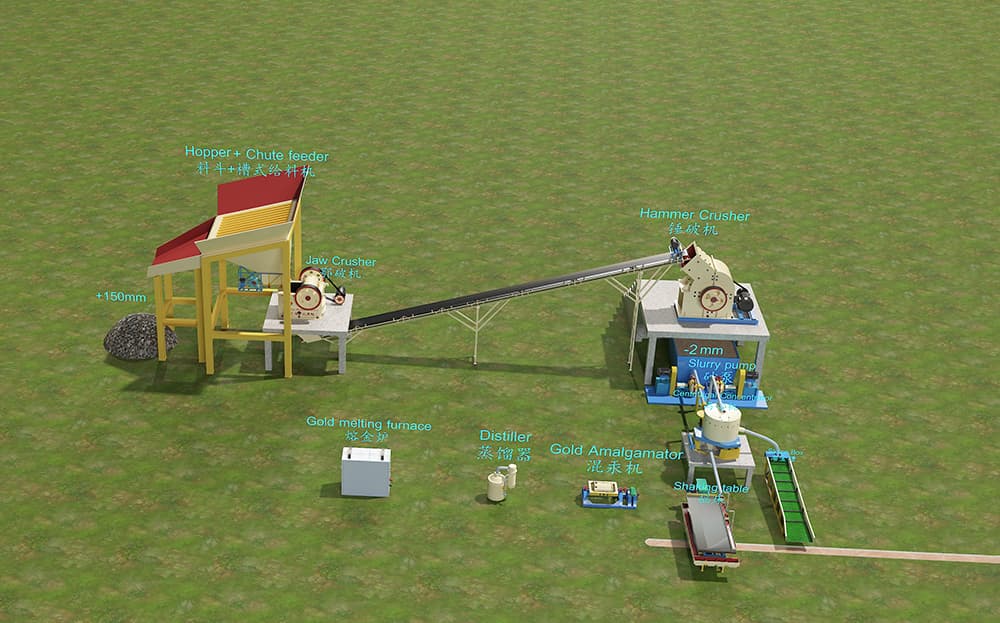

Crushing

The gold in some alluvial gold deposits is wrapped in rock particles or associated with minerals. In order to release the gold ore, the gold ore needs to be crushed first. Another situation is that alluvial gold ore contains cemented mud masses, some of which have a particle size of more than 100 mm. Crushing can separate the slime from the ore particles, exposing the gold particles and creating favorable conditions for mineral processing. Hammer crushers, jaw crushers, and vibrating screens are commonly used in crushing.

Washing and screening

Placer gold deposits usually contain large amounts of weathered clay, which encapsulates the gold ore and forms cemented masses or mud bodies. Therefore, ore washing operations are crucial for extracting gold ore. The ore washing process includes water soaking, flushing, mechanical agitation and screening to effectively separate the ore from the ore slime. After the ore washing treatment, the sediment will be broken up and separated, and a large amount of gold-free gravel can be screened out, which will improve the grade of the ore and facilitate the subsequent mineral processing work. Commonly used placer gold washing and screening equipment include vibrating screens, trommel screens, trommel Scrubber, etc.

Gravity separation

In the case where gold exists in the form of free gold particles in sand gold deposits, the gold deposits can be efficiently enriched through gravity separation. Gravity separation has simple operation, low investment, and no secondary pollution. It is the most economical and environmentally friendly treatment method for this type of ore. At the same time, for vein gold ore containing other heavy minerals, the gravity separation process after crushing is also an effective way to quickly recover gold and associated minerals.

In the gravity separation method, more than two types of gravity separation equipment are often used to process minerals of different particle sizes and improve the gold ore recovery rate. Mainly use Jig separator, shaking table, sluice box, gold centrifugal concentrator, spiral chute, etc.

Flotation

Flotation is suitable for gold placer containing sulfide. During flotation, the buoyancy of the bubbles in the water floats the gold-containing sulfide minerals, thereby achieving the purpose of separation.

For vein gold ore or fine-grained gold ore, a single gravity separation method cannot obtain the ideal gold concentrate, and a combined process is required to achieve it. Commonly used processes include:

(1) Gravity separation-flotation: Gravity separation to recover coarse gold in the ore, tailings flotation.

(2) Flotation-gravity: flotation is the main method, suitable for close symbiosis between gold and sulfide, and can obtain a higher recovery rate than single flotation.

JXSC Alluvial Gold Processing Plant in Romania

JXSC has provided complete set processing plant machines &all accessories for Romania customer alluvial gold Processing Plant. While we offer the details layout design with base constructions drawing accordingly.

The process as below:

Screening: The vibrating screen screens out 0-4mm sand.

Rougher Separation: The centrifuge roughly selects 0-4mm sand, and the tailings are sent to the sluice box for recycling.

Concentration: The concentrate from the centrifuge and sluice box is screened with a sieve. The 0-2mm concentrate is selected on the

shaking table. The +2mm concentrate will use gold pan to refine again.

Use equipment: Centrifugal concentrator(STLB80)、Sluice box(1x6m)、Shaking table(2100x1050mm)、Water pump(IS80)