Turnkey Solutions

Beach Sand Beneficiation Plant

Beach sand beneficiation refers to separating and concentrating valuable minerals from beach sand deposits. The composition of beach sand varies, but it often contains valuable minerals such as ilmenite, rutile, zircon, monazite, garnet, and others. These minerals are important for various industrial applications, including producing titanium dioxide, zirconium, and rare earth elements. Beach sand beneficiation methods aim to extract and concentrate these valuable minerals.

The methods of beach sand beneficiation can vary according to the properties of the target minerals and the differences in sand composition. The main beneficiation methods of beach sand include gravity separation, magnetic separation, and electrostatic separation.

Process Description

General steps for beach sand beneficiation:

- Pre-screening

First pre-screened the beach sand, removedlarger impurities, stones and organic matter to obtain relatively pure sand. - Heavy MediaSeparation

Using the heavy media separation method, the sand material is divided into components of different densities by adjusting the buoyancy in the mortar. This helps separate heavy mineral particles containing valuable minerals.

- Magnetic Separation

Using magnetic differences, magnetic separation equipment is used to separate magnetic minerals (such as ilmenite, magnetite) from non-magnetic minerals. - Gravity Separation

Use gravity separation equipment, such as spiral chutes, centrifugalmachine to re-separate the sand to obtain a higher concentration of valuable minerals. - Chemical Leaching

The chemical leaching method can be used for seaside sand containing rare earth minerals. The target minerals are leached out using acid solutions, and then separated and purified through chemical reactions and precipitation. - Electrical Separation

Using electrical differences, minerals with different electrical properties are separated through electrical separation equipment. This is often used in the separation of beach sand containing electrically charged minerals such as zircon. - Screening and Vibration Sorting

Using screening and vibration sorting equipment, the particles are sorted according to their size and shape, so that valuable minerals can be further purified. - Drying

Drying refers to drying the concentrated minerals. Ovens, dryers, and other equipment are usually used for drying. Dried minerals can be better stored and transported.

Specific beneficiation steps may vary due to differences in ore composition.

Related Case

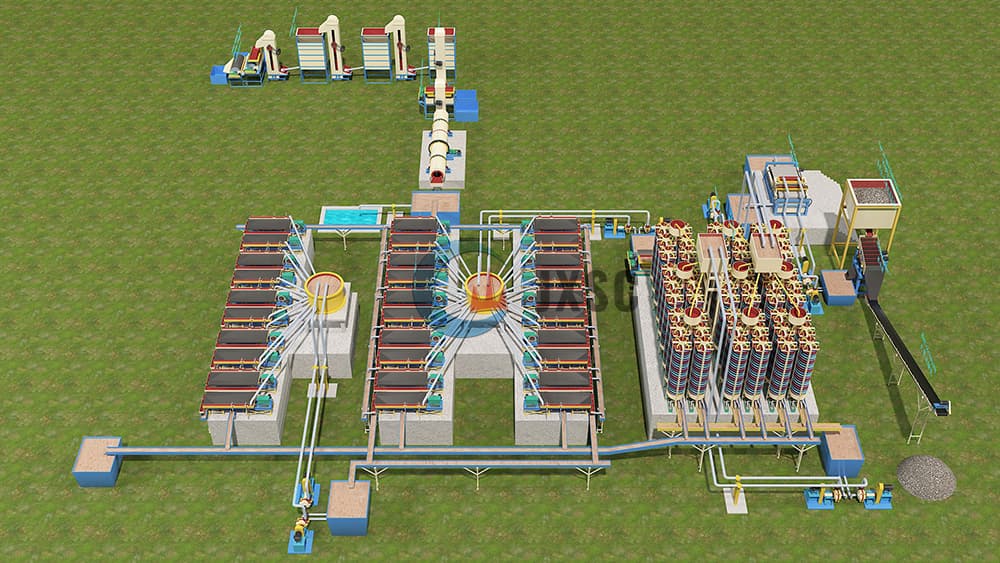

Capacity: 100tph

Raw Ore: Above 2mm impurities are removed, need separate rutile, monazite, zircon, ilmenite, magnetite from the beach sand

Equipment: Feeder, vibrating screen, belt conveyor, slurry pump, magnetic separator, spiral chute, shaking table, dryer, electrostatic separator.

100TPH Beach Sand Process Flowchart

- The excavator or loader feeds raw sand to the raw ore bin and then feeds the vibrating screen through the electromagnetic vibrating feeder.

- Vibrating screen with one layer screen with 2mm mesh size to remove impurities above 2mm.

- Below 2mm go to magnetic separator by slurry pump for separating magnetite.

- Output of the magnetic separator is sent to the spiral chute by a slurry pump. The gravity separation method is used to remove light minerals.

- Spiral chute gravity separation plant has two stages: the middling from the first stage spiral chute plant goes to the second stage spiral chute for reprocessing.

- All concentrates from two stages of spiral chute plants are sent to 1st double drum magnetic separator for separating ilmenite.

- Output of 1st double drum magnetic separator is sent to the shaking table by slurry pump for removing light minerals by gravity principle.

- Shaking table has two stages: the middling from the first stage shaking table is sent to the second stage shaking table for further processing by a slurry pump.

- All concentrate from the two stages of shaking the table plant is sent to the rotary dryer for drying material.

- After drying, dry materials through hoist machine to 2nd double drum magnetic separator for separating ilmenite.

- Other minerals from 2nd double drum magnetic separator go to 1st electrostatic separator through the hoist machine for separating the rutile, other minerals through the hoist machine to 2nd electrostatic separator for separating the rutile, other minerals through the hoist machine to the 3rd electrostatic separator for separating rutile.

- Other minerals from the 3rd electrostatic separator go to the double roller strong magnetic separator via a hoisting machine for separating zircon and monazite.