Turnkey Solutions

Cil Gold Processing Plant

CIL (Carbon In Leach) is an activated-carbon leaching method for extracting gold. It is a process of adding activated carbon to the slurry and simultaneously leaching and adsorption, which simplifies the leaching and cyanide process of the CIP gold processing plant.The CIL processing plant is suitable for processing flotation gold concentrate or mixed mercury, gravity gold tailings, argillaceous oxidized ore, and sulfide rock gold. The CIL process is widely used in processing high-grade large gold mines and gold mines with highly associated silver and copper.

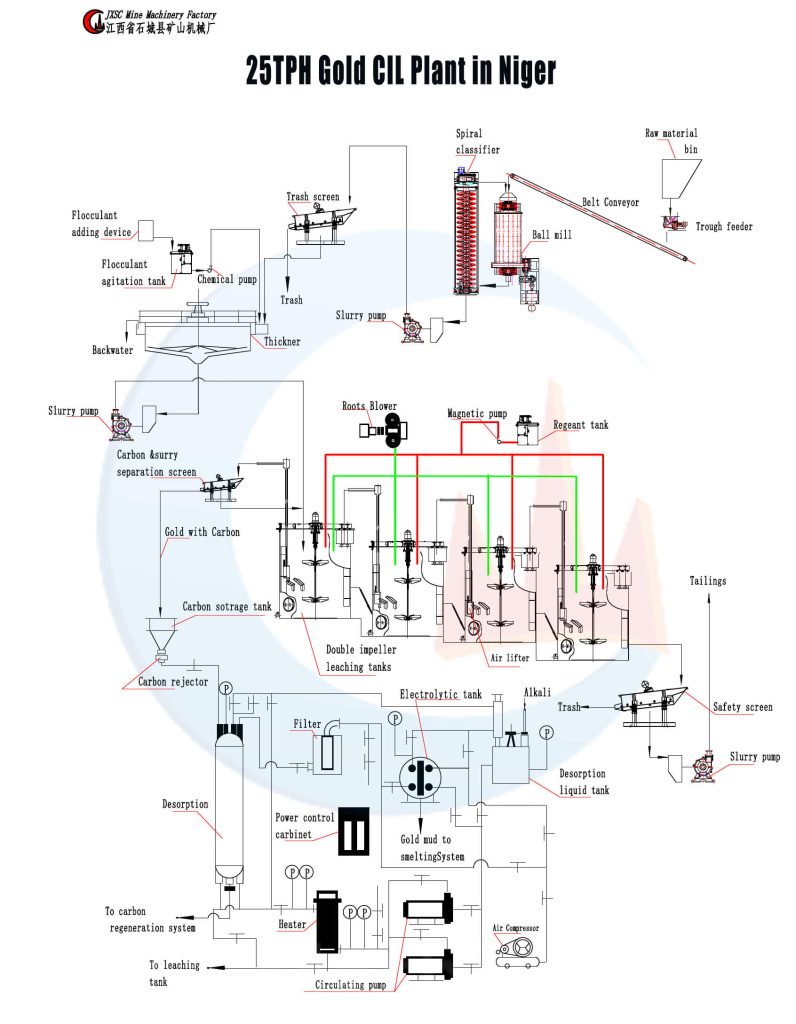

Process Description

The production process of the CIL carbon leaching method for gold extraction in the gold mine production line mainly includes stages such as impurity removal, pre-leaching concentration, leaching and adsorption, elution & electrolysis, wet smelting, activated carbon regeneration, tailings filtration, and sewage treatment.

1. Pulp impurity removal: Before adsorption, it should remove impurities in cyanide pulp like sawdust to prevent sawdust from adsorbing gold in the pulp and mixing into the rich carbon. At the same time, it should prevent sawdust from blocking the charcoal screen.

2. Pre-leaching concentration: The slurry will be dehydrated by a thickener before leaching to achieve the appropriate leaching concentration. The concentration not only affects the leaching time but also affects the suspended state of activated carbon.

3. Leaching and adsorption: The impurity-removed and concentrated pulp will be pumped into a high-efficiency leaching tank in a ladder-like distribution, generally arranged in series with 5-8 tanks. Cyanide is added to the first two tanks, and activated carbon in the last five tanks. The slurry and activated carbon are countercurrent adsorbed. Activated carbon becomes gold-loaded carbon due to the adsorption of gold in the slurry. After activated adsorption, the gold-loaded carbon slurry will go to the carbon extraction screen, and the carbon extraction screen separates the activated carbon and the slurry.

4. Gold-loaded carbon desorption and electrolytic: The desorption of gold-loaded carbon and the electrolytic deposition of liquid gold are completed in a closed system. Under high temperatures and pressure, gold-loaded carbon will quickly absorb and electrodeposit into gold mud and poor carbon. The processing equipment includes desorption columns, pickling tanks, heaters, filters, desorption liquid tanks, electrolytic tanks, etc.

5. Smelting: After the acid washing and impurity removal, the obtained gold mud can be smelted into a gold bar. By adopting the wet metallurgy method, the purity of the gold bar can reach over 99.99%.

6. The regeneration and utilization of activated carbon: The desorbed activated carbon goes through acid-washing to remove carbonate and other accumulated substances. After several times of reuse, it needs to be thermally activated to restore the adsorption activity of the carbon. The equipment includes an activated carbon regeneration kiln, water quenching tank, fine carbon separation screen, etc.