Turnkey Solutions

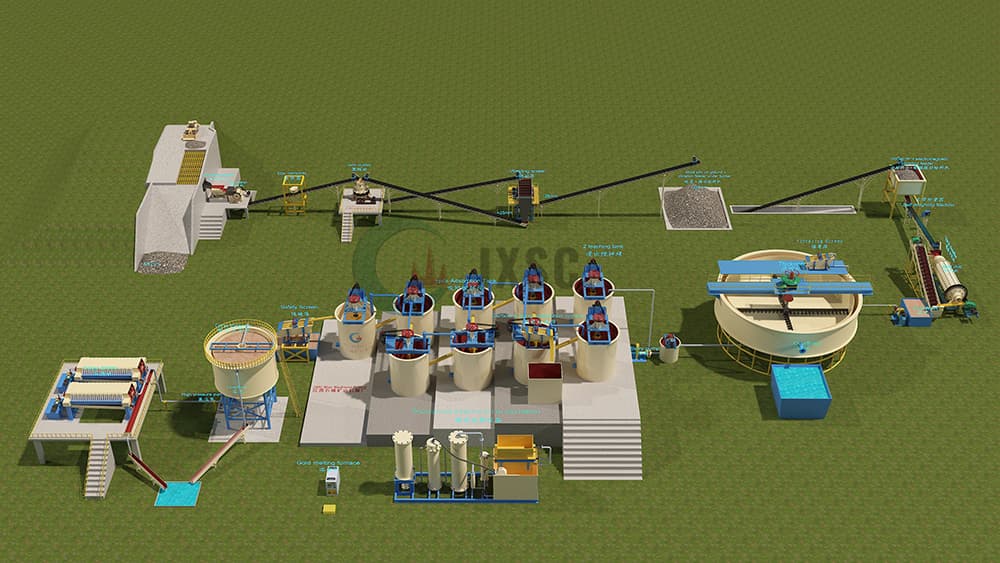

Cip Gold Processing Plant

CIP (Carbon In Pulp), also known as carbon slurry method for extracting gold. It is an unfiltered cyanide slurry process that directly uses activated carbon to adsorb and recover gold from cyanide slurry. It includes seven operational stages: preparation of slurry leaching, cyanide leaching, adsorption of activated carbon, desorption of gold-loaded carbon, obtaining gold mud through electricity, recycling of gold removal carbon, and treatment of leaching slurry.

Process Description

The main steps of the Carbon Pulp Process (CIP) include feeding, crushing and screening, grinding, leaching pretreatment, leaching, activated carbon adsorption, gold-loaded carbon desorption and electrolysis, gold melting, carbon recovery and utilization, and tailings water recovery.

1. Feeding+crushing screening process

The vibrating feeder evenly transports the raw ore to the jaw crushers, and the fine jaw crusher crushes the rock below 20-25mm. The +20mm material is back to the fine jaw crusher for further crushing. The 0-20mm powder material is transported to the ball mill for grinding.

2. Grinding

Grind the 0-20mm material from the jaw crusher into fine powder to release gold from the stone. The discharge from the ball mill enters the spiral classifier or hydrocyclone for classification. The return sand (bottom flow) from the classifier or cyclone will return to the ball mill for further grinding. The overflow of a classifier or cyclone are small particles, with 80% less than 200 mesh (0.074mm).

3. Leaching pretreatment

Pump the 200 mesh slurry to the thickener. Before the slurry enters the thickener, there is a safety screen to prevent coarse particles.

The slurry under the screen directly enters the thickener, and it needs to add flocculants to the thickener to accelerate sedimentation. The overflow water from the thickener enters the sedimentation tank, and the settled water is recyclable. The function of a thickener is to allow the slurry to reach a certain concentration before entering the following leaching tank.

4. Leaching:

The bottom flow of the thickener will enter the mixing tank with a height difference. Then the slurry pump pumps the mixed slurry into the double impeller leaching tank and adds sodium cyanide, without activated carbon.

5. Activated carbon adsorption treatment

After the gold is leached and dissolved in the solution, the slurry flows into the double impeller stirring adsorption tank at the back, where activated carbon is in it. The activated carbon adsorbs the gold in the slurry to become the gold-carrying carbon, then extracts gold by a carbon extractor.

6. Desorption and electrolysis of gold loaded carbon

The gold-loaded carbon is filtered through a linear vibrating screen to remove impurities. The gold-loaded carbon enters a normal temperature and pressure desorption electrolysis system, and after electrolysis, obtains gold mud. Then dry the gold mud in an oven. Finally, use a gold melting furnace to melt the gold bars.

7. Gold-loaded carbon recycling:

The desorbed gold-loaded carbon can be dried in a drying oven and reused.

8. Tailings water recovery system:

The tailings from the adsorption tank first enter the linear screen to screen out the carbon shavings. The tailings slurry is pumped to the cone concentration tank to reach the appropriate slurry concentration before filtration. Then, the tailings slurry is fed to the plate filter press by a high-pressure pump for filtration and recovery of tailings water. The filtered dry tailings are transported by truck and the tailings flow into the water tank.

If there is no request to recycle tailings water or treat tailings, add some bleaching powder to the tailings to treat acidic chemicals and reduce their impact on the environment. Then, the tailings can be discharged to distant places through water pipes.

Related Case

JXSC has designed a complete set Flowchart and provided a complete set processing plant machines &all accessories for Kenya customer 12TPH (300TPD) Gold CIP Plant.

Also Have Provided After-sale Engineer Service, sending engineers to the Mine site for installation&commissioning guidance.

The Main Machines and accessories include the following:

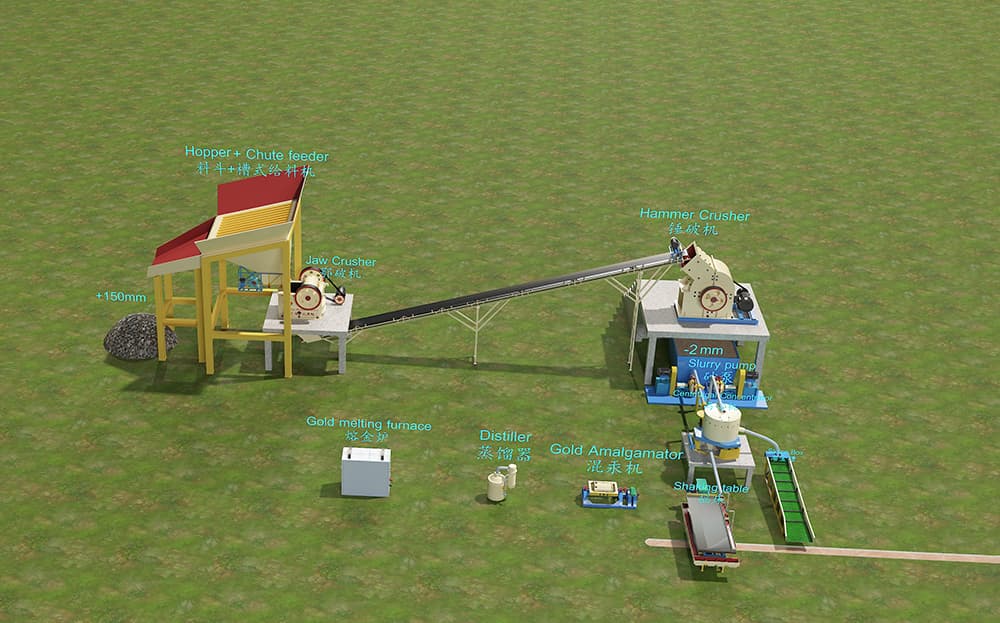

- Feeding + Crushing system crush rock from 210mm to below 5mm :

Feeding hopper+chute feeder+ rough Jaw crusher+belt conveyor+fine jaw crusher+vibration screen+ roller crusher

- Grinding System (grinding material to small powder 200mesh) :

Storage bin+ electromagnetic vibration feeder+ belt conveyor+ball mill+hydrocyclone

- Leaching Pretreatment :

Include thickener + agitation tank ( for adjusting the density of slurry after thickener) +liner vibrating screen

- Leaching and Activated Carbon Adsorption processing :

include 2pcs double impeller Leaching agitation tank+ 7pcs double impeller adsorption agitation tanks+ roots blower (work for adsorption agitation tank)+ liner vibrating screen for tailing dewatering+ liner vibrating screen for screening carbon+ cabon extractor +cabon screen

- Gold-loaded carbon desorption and electrolytic Stage:

Include: Normal temperature& normal pressure Elution & Electrolysis system Oven for gold mud+ gold smelting furnace

- Carbon kiln for carbon regeneration

- Tailing Water recycle system :

High-pressure slurry pump+plate filter press+cone slurry tank for making the suitable density of the slurry, before sending it to the filter

- Five Reagent adding devices system:

Each system includes a reagent agitation tank and a reagent slurry pump reagent tank.

1) Flocculant make-up system for thickener.

2) Sodium cyanide reagent make-up system for 2pcs leaching agitation tank

3) Lime make-up system for 2pcs leaching agitation tank (for PH control)

4) Sodium hydroxide&hydrochloric acid reagent make-up system for cone agitation tank

5) Sodium hydroxide&&clean water&sodium cyanide reagent make-up System for Elution & Electrolysis system

- Water pumps for water supply to complete plant.

- Slurry pumps for plant

- Complete set of electric control panels

- Complete set cables&wires

- Diesel Generator for plant machines power

- Complete set of water pipes &slurry pipes