Turnkey Solutions

Diamond Mining Process

The diamond type is divided into alluvial diamond and rock diamond. The former has a relatively simple beneficiation process, which only requires washing, screening, gravity separation, and concentration to separate sand and rock minerals. Therefore, diamond beneficiation includes two different methods: one is to extract diamonds from sand minerals, while the latter requires crushing, screening, gravity separation, and concentration to separate diamonds.

Process Description

The diamond beneficiation production line is very similar to the sand gold production line. They usually consist of a washing machine plus a sorting machine. Ore washing equipment can be divided into trommel screen and rotary scrubber according to the different mud content. The separator usually uses a jig machine.

1. Crushing and screening

For large rock diamond, the vibrating feeder transports them into the stone crusher. Then the crushed material goes to the vibrating screen, and the material reaches the required size will be transported to the following processing machine. Alluvial diamonds don’t need a crushing process and only require washing and screening equipment.

2. Washing and Screening

Trommel scrubber and vibrating screen are used to remove impurities such as clay and mud, and the materials are graded at the same time.

3. Gravity separator

Diamonds have a higher specific gravity than gangue and are suitable for separation with a jig separator. Diamonds settle to the bottom under the action of water flow and vibration, while lighter impurities float on the water surface and are discharged with the overflow.

4.Diamond recovery

The heavy fraction containing the diamonds is further processed to recover the diamonds. Various methods can be employed, including X-ray sorting, grease tables, and hand sorting, depending on the size and quality of the diamonds.

Mobile, Portable and Small Scale Diamond Washing Plant for Sale

JXSC provides an efficient and economical mobile diamond processing plant. Mainly composed of trommel screen and jig separator.

1. The mobile jig separator is very suitable for alluvial minerals without clay. If the material contains clay, a mineral washing machine can be used instead of the drum screen.

2. Equipped with complete water system, include water pump, water spray and pipes, wash thoroughly for the minerals.

3. With feeding hopper, mobile system with rubber wheels, easily move to anywhere.

It is often used to process diamond ores, gold ores and tantalum-niobium ores. When used in gold mines, it can also be used in conjunction with gold sluice boxe and shaking table to further purify minerals.

Related Case

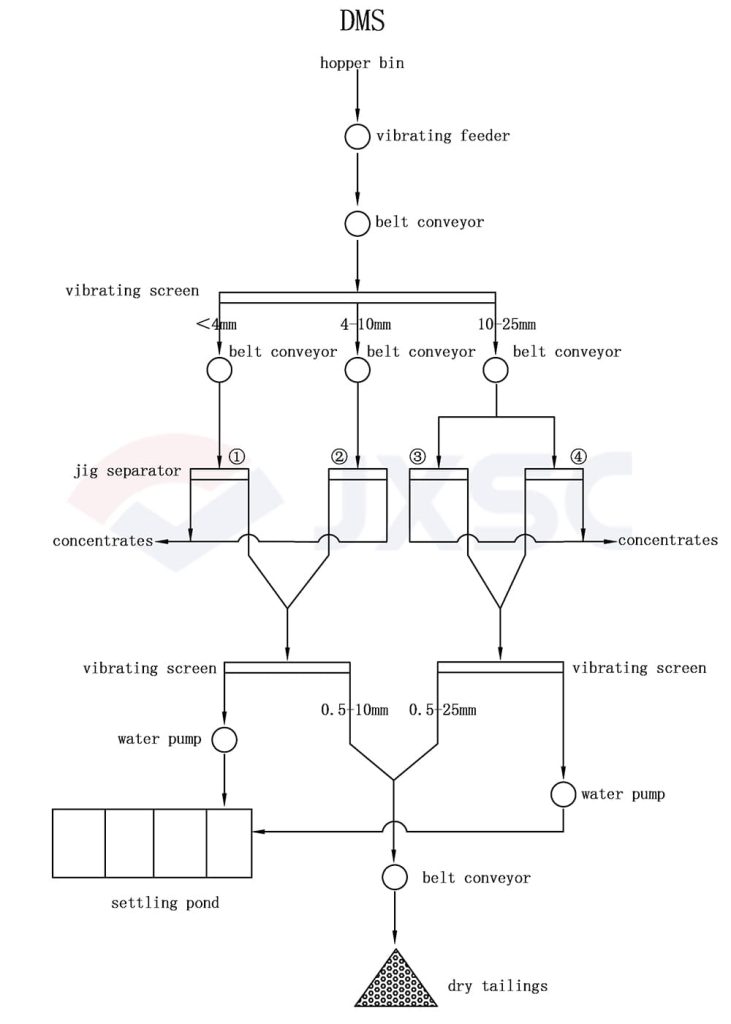

Raw ore information: Kimberley diamond veins, placer, and rock mixed ore, there are diamonds in the stone, and the friction coefficient of the stone is relatively large. The raw ore contains more slime and is not easy to clean. The diamond size in the placer is 1-25mm.

The customer has two old processing lines, both of which have been working for a long time. All have screen washing and DMS sorting systems.

Customers require wash and separate diamond ore sizes of 2-25 mm. Other sizes of materials are not needed.

Process flowchart as below:

1. First use a vibration feeder with the grizzly bar to remove size stones,

2. smaller particles go to the Trommel scrubber washing machine to wash and clean the diamond, then separate 2-25 mm particles.

3. Because it is probable there will mix with some other sizes of particles in 2-25 mm, it needs to use the high frequency to separate the 2-25 mm material again to remove -2mm and +25 mm particles.Equipment

1. feeding hopper

2. vibration feeder: 1 set, 6000*1300mm

3. jaw crusher: 1 set, PE 750*1060

4. trommel scrubber: 1set, 2.4m*(6m drum length +2m screen length)

5. vibration screen: 1set, JXSC-2445, 2layer PU screen

6. belt conveyor: 750*30m, 12set

7. vibration feeder: 1set, 380*95mm

8. cone crusher: 1set, LYH-300

9. vibration screen: 1set, JXSC-1845, 2layer PU screen.

10. water pump: 3set 12inch, 2set 8inch, 4sets 6 inch

11. slurry pump: 3set 4 /3inch, 1set 8/6inch

12. vibration screen: 1set, JXSC-1536, 2 layers PU screen

13. jig machine: 4set JT4-2 double gearbox and motor

14. full set electric control panel and cables

15. HDPE main water pipe, water pipe inside the plant, connection parts of water pipes, flange, valves, etc.

16. slurry pipes