Hardrock Gold Processing Plant

Rock gold refers to gold particles embedded or disseminated in rock gold mines associated with rocks. When beneficiation, it will adopt a crushing and grinding process to achieve individual dissociation of the gold particles, and then use gravity or flotation methods to separate and enrich the gold ore. The simple production process of extracting gold from rock gold ore includes crushing and screening, grinding, separation, etc.

Process Description

Crushing and screening

The original rock gold ore is relatively large, so it needs to be crushed first. The vibrating feeder transports the gold ore by a belt conveyor to a jaw crusher for rough crushing, and then the materials from the coarse jaw crusher are sent to a fine jaw crusher or cone crusher for secondary crushing. After crushing, the particle size of the gold ore is below 25mm. Those materials that meet the requirement are screened out through a vibrating screen and enter the next stage.

Grinding

After crushing, the gold ore enters the ball mill for grinding treatment. The ball mill will grind the material to 200 mesh. The ground product will go to a spiral classifier for classification. The spiral classifier will separate mud, weeds, and other substances from the gold ore, improving the grade of the gold ore.

Separation

Gravity Separation

For some rock gold ores, a good recovery rate can be obtained by gravity separation after crushing or grinding. Gravity selection usually includes two processes: rough selection and selection. In this process, centrifugal concentrator and shaking table are often used. After the grinding process, multiple groups of shaking tables are connected to obtain gold ore through multiple sorting. Or first use a Centrifugal Concentrator to roughly select minerals, and then use two sections of shaking tables to sort the Centrifugal Concentrator’s concentrate and tailings respectively. Sometimes a sluice box is also used to sort the Centrifugal Concentrator’s tailings.

Flotation Separation

Flotation is mainly suitable for the re-separation of sulfide gold ores where gold and sulfide minerals coexist, as well as some gold-rich oxidized ores, oxidized gold ores and gold-rich tailings. Flotation can effectively enrich gold and other valuable minerals and improve the recovery rate of gold.

In the separation operation, the commonly used flotation equipment is mainly mechanical agitation flotation machines (SF type, JJF type, BF type), inflatable agitation flotation machines (XCF type, KYF type) and flotation columns. Among them, SF type, JJF type and XCF type are suitable for rough selection and sweeping operations, and KYF type and BF type are suitable for rough selection and fine selection.

The equipment includes a coarse jaw crusher, fine jaw crusher, cone crusher, hammer crusher, vibrating screen, belt conveyor, wet pan mill, ball mill, spiral classifier, hydrocyclone, gold centrifugal concentrator, shaking table, etc.

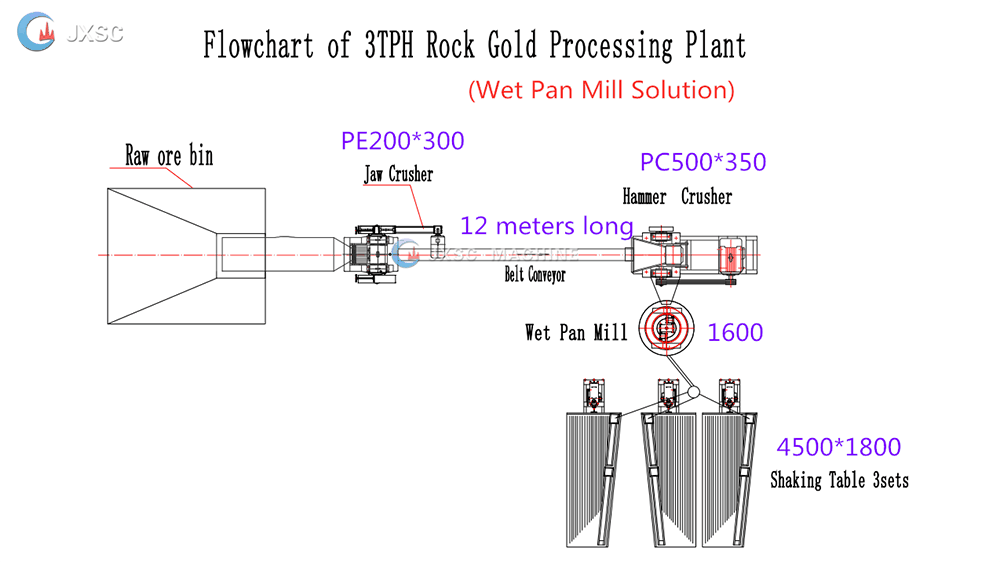

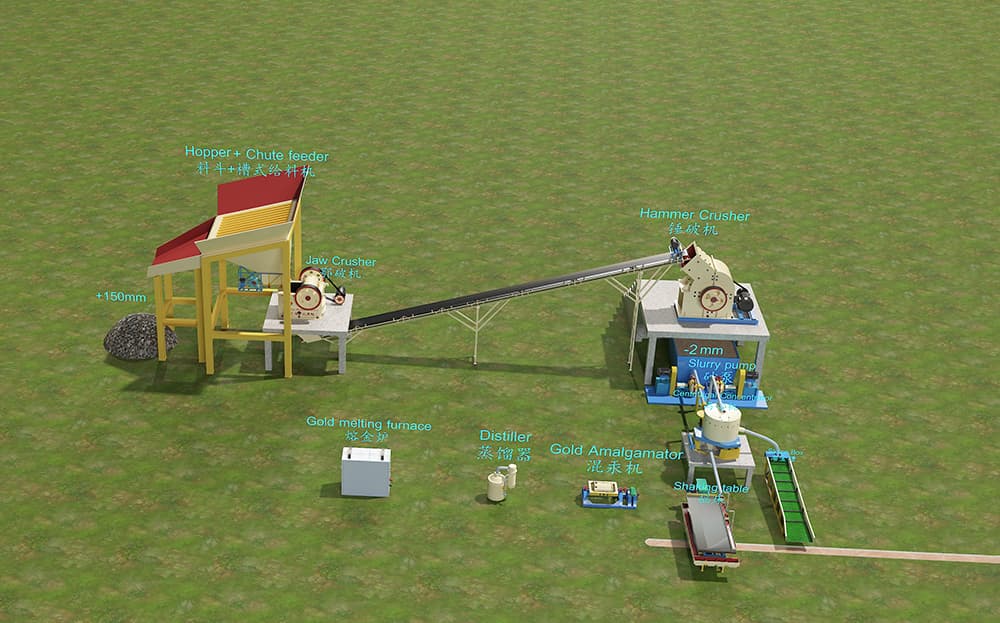

JXSC 3TPH Rock Gold Process Plant In Ghana

Rock gold mine, with a maximum feed of 150mm, Rock need be milled to 1mm below for liberate fine gold completely. JXSC provides a complete set of equipment including diesel Generator and spare parts.

1.Crushing and Griding Raw ore are manually fed to jaw crusher for crushing to 20-30mm, the discharge of jaw crusher through belt conveyor go to hammer crusher for further crushing to 6mm, then go to wet pan mill for grinding to finer powder 1mm below.

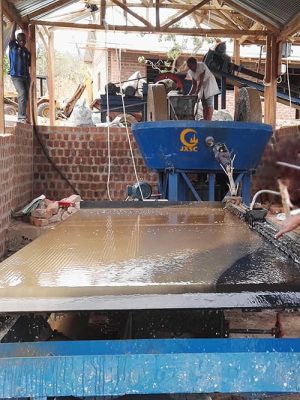

2. Gravity Separation The discharge of wet pan mill is powder slurry, utilize slurry pump to send it to shaking table for recovering fine gold.

We Provide: Jaw Crusher(PE200*300), Hammer Crusher(PC-500*350), Wet Pan Mill(1600), Shaking Table(6S-4500), Belt Conveyor(B500*10), Gold Smelting Furnace(15A), Diesel Generator(100KW), Jack hammer(YT28), Spare parts