Turnkey Solutions

Iron Ore Beneficiation Plant

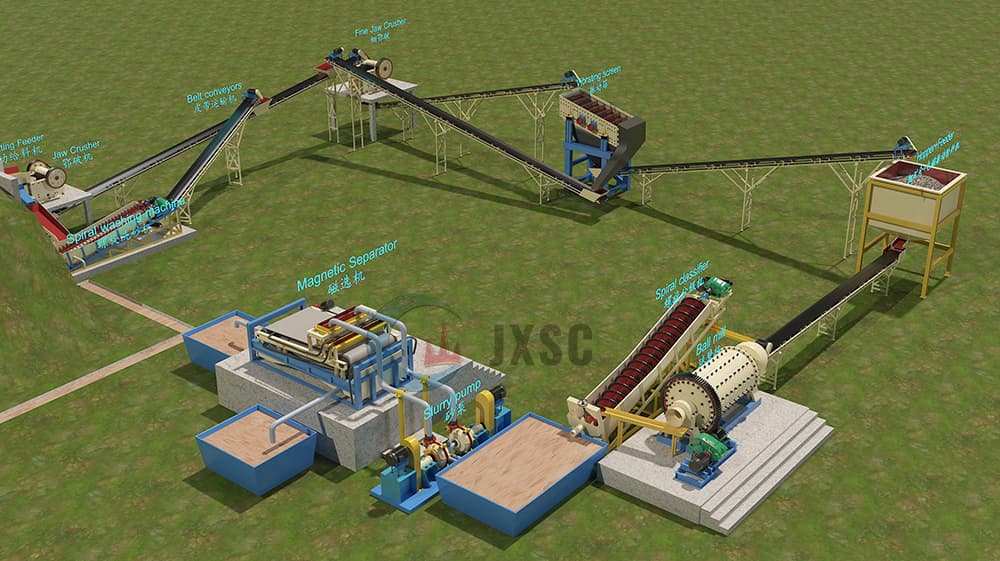

Iron ore (the ore of oxide mineral magnetite) is a granular aggregate with magnetism and wide distribution. According to the different types of iron ore, it includes single magnetite and mixed ore. According to the properties of iron ore, there are multiple different process solutions. Mineral processing plants generally adopt a three-stage crushing process of coarse, medium, and fine crushing to crush iron ore. The jaw crusher is widely used for coarse crushing, while a cone crusher is for medium and fine crushing. Through rough crushing, the qualified particle size enters the ball mill. The specific process is as follows.

Process Description

Crushing: The jaw crusher crushes the iron ore to the required size and enters the following equipment.

Grinding: The material from the jaw crusher enters the ball mill. After grinding, the fine material enters the spiral classifier for classification. Based on the principle that the density of solid particles and the speed of precipitation in the liquid varies to wash and classify the material.

Magnetic separation: Finally, the graded iron ore enters a magnetic separator for separation. It utilizes the different specific magnetization coefficients when passing through a magnetic separator to separate the iron minerals.

Drying: Feed the iron powder to a rotary dryer, and the dryer in the beneficiation will remove the moisture of the iron powder to obtain high-quality iron concentrate.

Alluvial iron ore

Due to the sand-like nature of the alluvial iron ore, which is composed of sand and gravel, the particle size is generally under 5mm. For this reason, the beneficiation process is relatively simple, without the need for coarse or fine crushing. If there is a lot of sand in the original ore, clean it with Trommel washing screen equipment and then beneficiation with gravity and magnetic separation equipment.

Related Case

Ore type: Alluvial ilmenite with clay

Process

- The truck unloads the material to the hopper. The vibrating feeder under the hopper transports the material evenly to the trommel scrubber for clay washing and screening big stones.

- After trommel scrubber washing, the materials enter the spiral chute for separation.

3 . The iron concentrate from the spiral chute enters the magnetic separator for separation and improves the grade to get the final product.

Equipment:

Hopper, trommel scrubber, spiral chutes, magnetic separators, auxiliary equipment, etc.