Turnkey Solutions

Tailings Processing

The dry tailings process is a relatively safe and environmentally friendly method for tailings treatment. The dry discharge of tailings replaces the direct discharge of tailings by slurry pumps. Through dry discharge, wet tailings are dehydrated and stored, which enables the recovery and utilization of tailings water, and reduces environmental pollution, land occupation, and dam collapse hazards. It is an essential process for green mining construction.

Process Description

1. Tailings concentration and transportation

The tailings concentration and conveying system includes tailings concentration and dewatering equipment, tailings transportation pipelines, and tailings dispersion pipelines. This equipment will transport the tailings produced by the beneficiation plant to the tailings pond.

2. Tailings return water system

The tailings return water system includes a vertical pumping station, return water pipe, and return water tank for the sand discharge of tailings. It is for recovering water from the tailings concentration tank, dehydration, filtration, and waste water tank, and returning it to the beneficiation plant for production for reuse.

3. Tailings storage system

A tailings storage system, commonly known as a tailings pond, stores tailings slurry discharged from the beneficiation plant.

4. Tailings water treatment system

The tailings water treatment system includes sedimentation tanks, vertical pumping stations for transporting wastewater, leakage interception, and recovery facilities. It is for processing recycled water and tailings water that does not meet the discharge standards.

Related Case

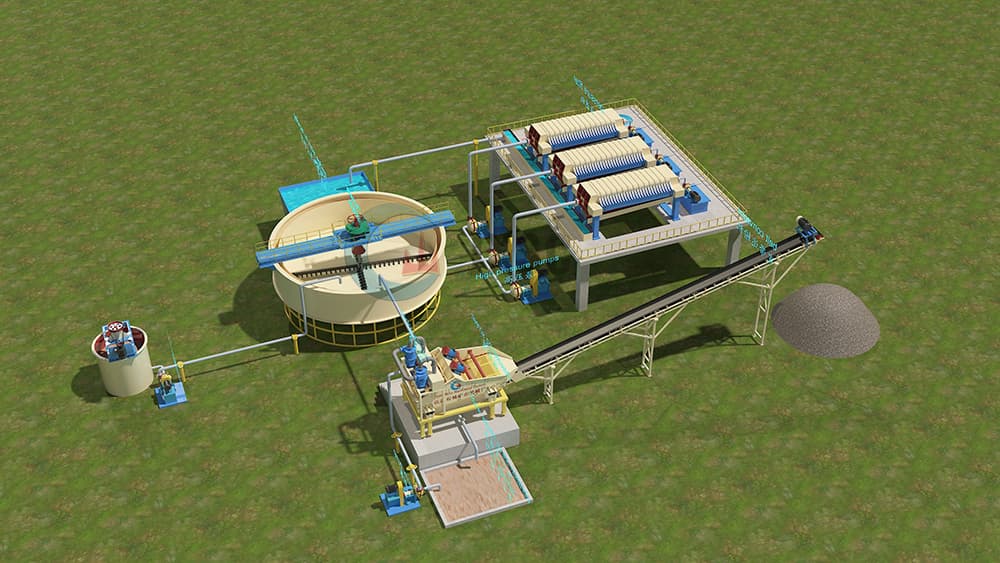

It is the 200tph tailing dry processing plant flow chart we designed for our client.

The main configuration includes a dewatering screen with a hydrocyclone, thickener, dissolving tank, filter press, belt conveyor, and related pumps.

Tailing process:

1)The slurry pump pumps the tailings to the hydrocyclone over the dewatering screen, and the underflow goes to the screen for dewatering. The vibration screen filtrates water and goes to the tailings slurry pool as a closed circle.

2)The overflow of the hydrocyclone goes to the thickener for precipitation.

3)At the same time, a flocculant will be added to the thickener. The flocculant will be put into a dissolving tank, and pumped into the thickener by a dosing pump.

4) The overflow from the thickener for recycling; the underflow from the thickener goes to the filter press.

5) The filter press for filtering, the solid is dry enough, and the belt conveyor will transfer it to the tailing pile.