The gold mining industry has been profitable for centuries, but it also generates a significant amount of waste called tailings. These tailings consist of finely divided rock and mineral residues that are produced during the mining process. If not managed properly, these tailings can pose environmental and safety risks due to their high water content and potential for toxic pollutants to leach into nearby ecosystems. To address these concerns, it is crucial to have efficient dewatering equipment that can remove excess water from the tailings before disposal or recycling. Most gold mine tailings require dehydration and dry discharge for environmental protection and safety reasons. This helps reduce pressure on tailings ponds and minimizes the risk of hazards. Additionally, it helps control pollution from the tailings to the environment. Common dewatering equipment for gold tailings includes hydrocyclones, thickeners, dewatering screens, and filter presses. Through comprehensive analysis, mining operators can determine the most suitable dewatering equipment for their specific needs, while also minimizing environmental impact and maximizing operational efficiency.

Introduction to Gold Tailings Dewatering Equipment

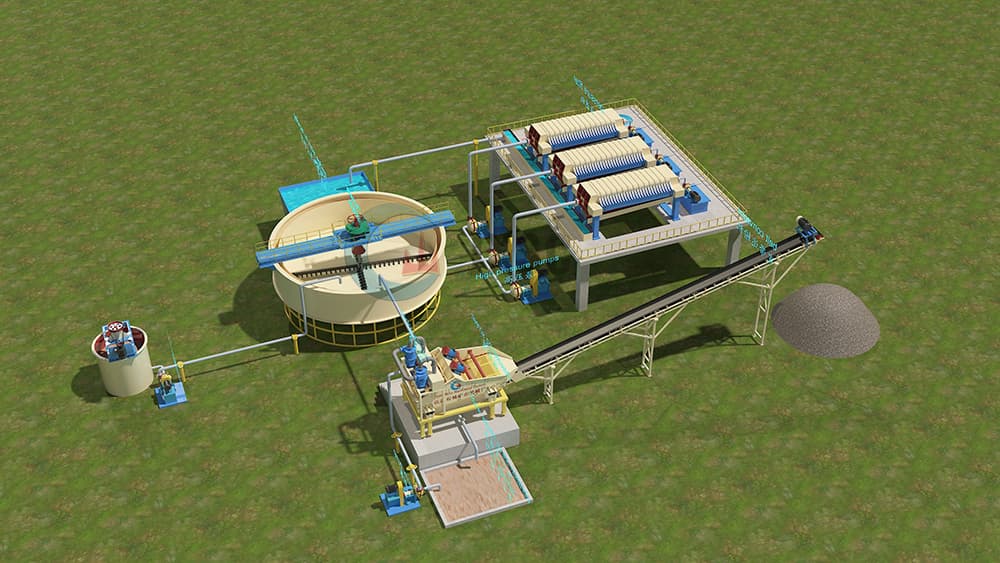

The system for concentrating and transporting tailings consists of equipment for tailings concentration and dewatering, pipelines for tailings transportation, and pipelines for dispersing tailings. This equipment is used to transport the tailings generated by the beneficiation plant to the tailings pond.

The system for returning tailings water includes a vertical pumping station, a return water pipe, and a return water tank for discharging sand from the tailings. It is designed to recover water from the tailings concentration tank, undergo dehydration, filtration, and be stored in a waste water tank before being returned to the beneficiation plant for reuse.

The system for storing tailings, commonly referred to as a tailings pond, is used to store the tailings slurry discharged from the beneficiation plant.

The system for treating tailings water includes sedimentation tanks, vertical pumping stations for transporting wastewater, facilities for intercepting and recovering leakage. It is used to process recycled water and tailings water that does not meet the discharge standards.