Beach sand deposits are sand deposits formed by waves and shore currents. Heavy mineral sands are washed up on the coast and deposited, while particles with small specific gravity and fine particle size are brought back to the sea. Beach sand contains rich rutile and zircon sand, which has important industrial value.

Beach sand zircon sand rutile minerals generally contain multiple minerals at the same time: zircon, monazite, rutile, hematite, ilmenite, iron or magnetitie, tin, garnet, silica, and usually need to combine multiple beneficiation methods to improve the grade of the concentrate.

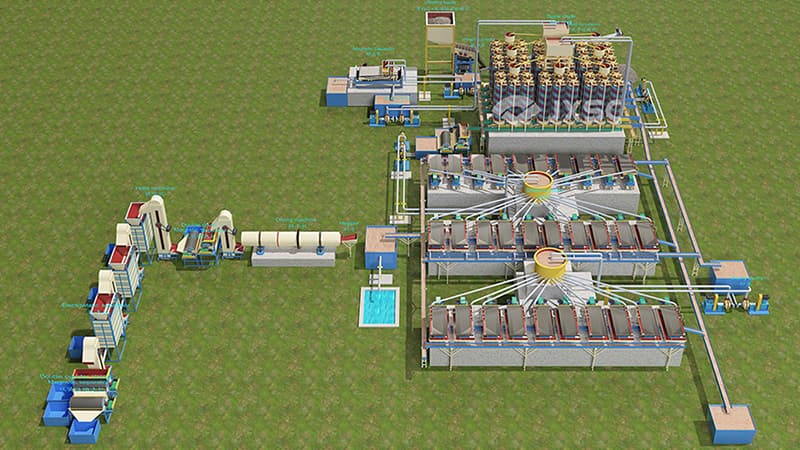

The beneficiation methods of beach sand ore mainly include gravity separation, magnetic separation and electrostatic separation. Since beach sand contains a large amount of heavy minerals, gravity separation is an effective method to separate these minerals. At the same time, the magnetite in it is magnetic and can be separated by a magnetic separator, while rutile can be selected by an electrostatic separator because it has strong conductivity.

Before designing a beach sand processing line, we need to analyze the ore sample to understand the mineral composition and proportion. Select the appropriate beneficiation equipment based on the results. For most beach sands, the following treatment methods can usually be used to obtain ideal concentrates.

Beach sand beneficiation process

Screening and ravity separation

1. Screening impurities: If it is untreated beach sand, there may be some impurities in it, which need to be screened out by high-frequency vibrating screen or trommel screen to remove impurities and gangue larger than 2mm.

2. Gravity separation: The feed particle size of beach sand is small and the processing volume is large. First, spiral chute is used for two-stage gravity separation. Spiral chute occupies a small area and has a large processing volume, which is very suitable for processing beach sand. The middlings of the first spiral chute enter the second spiral chute, the tailings of the two spiral chute are thrown away, and the concentrate enters the next process together.

Weak magnetic separation and gravity separation

3. Weak magnetic separation: For beach sand with a high magnetite content, a weak magnetic separator (drum magnetic separator) is used to remove most of the magnetite.

4. Gravity separation: Other minerals and a small part of magnetic minerals after magnetic separation enter the two-stage shaking table sorting process to remove the light gangue again. The intermediate ore from the first shaking table enters the second shaking table for sorting, the tailings from the two shaking tables are discarded, and the concentrate enters the next process.

Magnetic separation and electrostatic separation

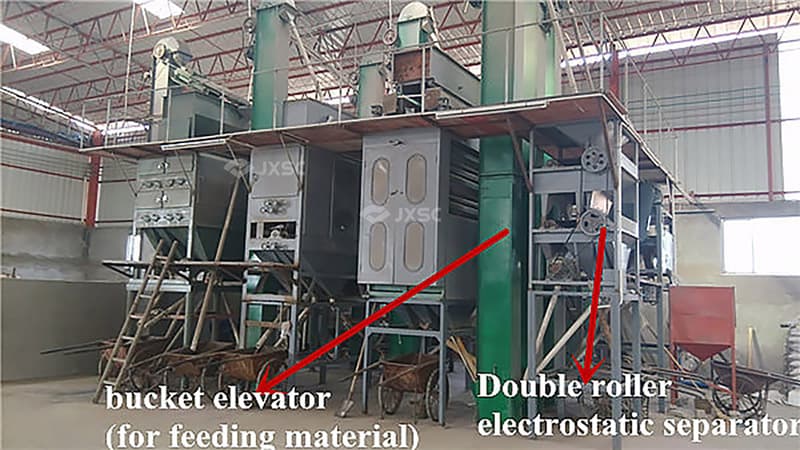

5. Drying treatment: The subsequent electrostatic separator and magnetic separator are dry processing equipment, so the concentrate produced by the shaking table must be dehydrated and dried. First, the water is removed by the dehydration screen, and then the dryer is used for drying.

6. Magnetic separation treatment: Use a high intensity dry magnetic Separator to remove weakly magnetic minerals in the concentrate, such as ilmenite.

7. Electrostatic separation treatment: Use an electrostatic separator to separate conductive and non-conductive substances. Rutile can be separated in this step.

8. Magnetic separation treatment: In order to further improve the grade of the concentrate, a high intensity dry magnetic Separator is used to remove weakly magnetic minerals, such as monazite and garnet.

The above is a commonly used beach sand beneficiation process. Different raw ore conditions also require the selection of appropriate magnetic separators and electrostatic separators according to the mineral composition. The higher the grade requirements, the more magnetic and electrostatic separation equipment is used, and the same equipment can also be sorted multiple times.

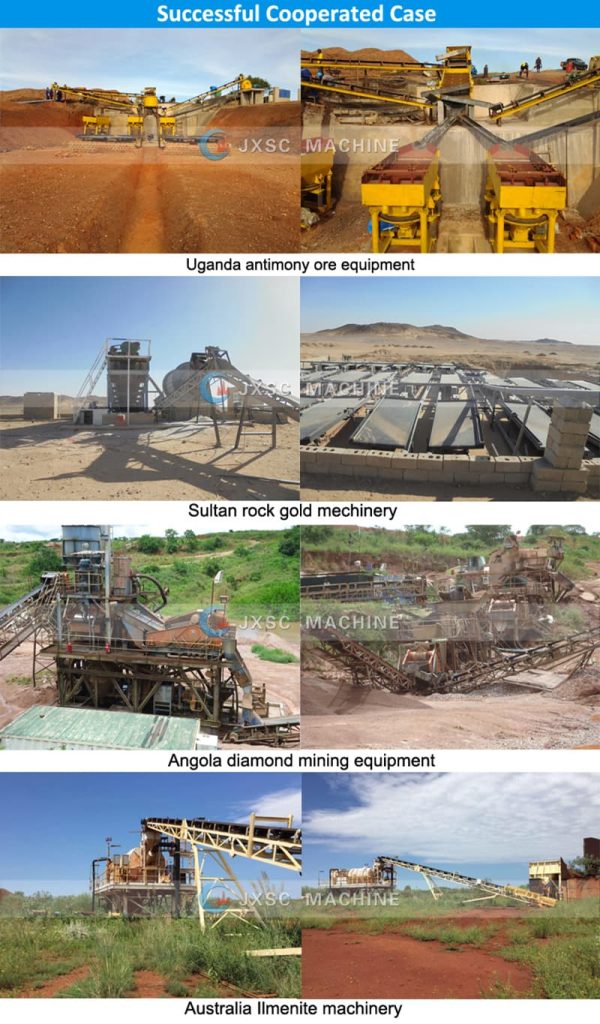

JXSC has 38 years of experience in the mining industry, and many experienced engineers provide professional technical support to customers. We focus on providing mineral turnkey solutions and full equipment sales services. We have served hundreds of customers at home and abroad over the years. Please send us your mineral mining information. A technician will contact you immediately.